Difference between revisions of "CLAS12 R1 Progress Reports"

m (→10/12/11) |

|||

| (124 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

[http://clasweb.jlab.org/wiki/index.php/CLAS12_Drift_Chambers The Drift Chamber Wiki at JLab] | [http://clasweb.jlab.org/wiki/index.php/CLAS12_Drift_Chambers The Drift Chamber Wiki at JLab] | ||

| + | |||

| + | [http://wwwold.jlab.org/Hall-B/clas12-web/ CLAS12 Web page] | ||

| + | |||

| + | 1) Dial toll free, 866-740-1260 | ||

| + | 2) Enter the 7 digit Access Code, 6074391, followed by the "#" key. | ||

| + | |||

| + | |||

| + | [http://128.82.116.28:2342/ODU+DAQ/ ODUs logbook] | ||

| + | |||

| + | |||

| + | [http://daq1.physics.isu.edu/cgi-bin/r1dc_dbPlotter.pl Database Viewer] | ||

| + | |||

| + | |||

| + | or if the DAQ computer is at the IAC | ||

| + | |||

| + | [http://daq1.iac.isu.edu/cgi-bin/r1dc_dbPlotter.pl Database Viewer] | ||

| + | |||

| + | service httpd start | ||

=Clean room Prep= | =Clean room Prep= | ||

| Line 15: | Line 33: | ||

= Jlab Stringing Prep= | = Jlab Stringing Prep= | ||

| − | + | [[CLAS12_CleaRoomPrep_2011]] | |

| − | = | + | =September 2011= |

| + | [[201109_R1ProgressRep]] | ||

| − | + | =October 2011 = | |

| + | [[201110_R1ProgressRep]] | ||

| − | [[ | + | =November 2011= |

| + | [[201111_R1ProgressRep]] | ||

| + | =December 2011= | ||

| + | [[201112_R1ProgressRep]] | ||

| − | + | =January 2012= | |

| + | [[201201_R1ProgressRep]] | ||

| − | [[ | + | =February 2012= |

| + | [[201202_R1ProgressRep]] | ||

| + | =March 2012= | ||

| + | [[201203_R1ProgressRep]] | ||

| − | |||

| − | [[ | + | [[ CLAS12_R1]] |

| − | + | [[ PhysicsCleanRoomParticleCountLog | ISU - Clean Room Particle Count Log]] | |

| − | |||

| − | [[ | + | =April 2012= |

| + | [[201204_R1ProgressRep]] | ||

| − | |||

| − | |||

| − | + | [[ CLAS12_R1]] | |

| − | + | [[ PhysicsCleanRoomParticleCountLog | ISU - Clean Room Particle Count Log]] | |

| − | |||

| − | [[ | + | =May 2012= |

| + | [[201205_R1ProgressRep]] | ||

| − | |||

| − | |||

| − | [[ | + | [[ CLAS12_R1]] |

| − | |||

| − | == | + | =June 2012= |

| + | [[201206_R1ProgressRep]] | ||

| − | |||

| + | [[ CLAS12_R1]] | ||

| − | |||

| − | + | =July 2012= | |

| + | [[201207_R1ProgressRep]] | ||

| − | |||

| − | + | [[ CLAS12_R1]] | |

| − | |||

| − | == | + | =August 2012= |

| + | [[201208_R1ProgressRep]] | ||

| − | |||

| − | + | [[ CLAS12_R1]] | |

| + | |||

| + | |||

| + | =September 2012= | ||

| + | [[201209_R1ProgressRep]] | ||

| + | |||

| + | ==JLab Shipment== | ||

| + | |||

| + | [[09122012_JlabShipment]] | ||

| + | |||

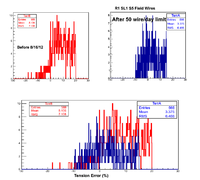

| + | [[File:925R1SL1S5_FieldTensionCompare.png || 200 px]] | ||

| + | |||

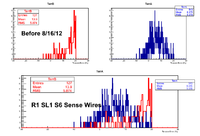

| + | [[File:925R1SL1S6_SenseTensionCompare.png || 200 px]] | ||

| + | |||

| + | [[ CLAS12_R1]] | ||

| + | |||

| − | == | + | =October 2012= |

| + | [[201210_R1ProgressRep]] | ||

| − | |||

| − | + | ==Potting== | |

| − | + | Epoxy Ratio 2.33:1 (Epon 828 Resin : Versamid 140). | |

| − | |||

| − | |||

| − | + | [[ CLAS12_R1]] | |

| − | |||

| − | + | =November 2012= | |

| + | [[201211_R1ProgressRep]] | ||

| − | [[ | + | =December 2012= |

| + | [[201212_R1ProgressRep]] | ||

| − | + | ==12/3/12 Meeting Notes with Mac and George at ISU== | |

| − | |||

| − | + | ===Construction Proceedures:=== | |

| − | + | Chambers outside cleanroom should have covers to keep dust off buss wires | |

| − | + | Cap 113 (Brown one) needs to be replaced on STB board. | |

| − | |||

| − | + | Need 2 amp fuse on 5 Volt supply to pre-amps. | |

| − | + | operate chamber STB voltage at 6 Volts | |

| − | |||

| − | |||

| − | + | Chamber grounding (ground through HV cable) | |

| − | + | ===Chamber operating procedures=== | |

| − | + | 1.) post amplifier in VME crate had 150 mV peak-peak noise | |

| − | + | 2.) Stop using the current ADB crate | |

| − | + | 3.) New nominal Voltages from Mac are | |

| − | + | S:F:G = 1300:-650: | |

| − | + | S/F = 2 | |

| − | + | S/G = 5/7 | |

| − | + | Signal output doubles every 75 Volts difference between sense and field | |

| − | |||

| − | + | 4.) Discriminator level for signals: | |

| − | + | 5.) Need to lower the HV trip current back to 1 microA. May increase it to 5 micro Amps when burning in. | |

| − | + | 6.) Change trip speed to 0.1 sec | |

| − | |||

| − | |||

| − | |||

| − | + | ===ISU Tasks:=== | |

| − | + | 1.) Install cover on top of chamber, top could be made from home insulation sheets that has been covered with paper or plastic sheeting. | |

| − | |||

| − | + | 2.) Install 208 Volts for ADB crates that will be sent by JLab to replace the one they have given us. | |

| − | + | 3.) solder jumpers onto HV boards, install them in January when George returns | |

| − | + | 4.) Mylar window on S1 chamber needs to have some tape and weather stripping redone or modified | |

| − | + | 5.) Get allen head 3/32 for torque wrench, remember to replace brass screws if they are removed for some reason | |

| − | + | 6.) do not do final instrumentation, purge covers, and dust covers on the last 2 chambers until checking with JLab, the may want to survey them after delivery | |

| − | |||

| − | |||

| − | + | ===JLab Tasks=== | |

| − | + | 1.) What are the fault conditions on the STB board when the power supply exceeds voltage/current | |

| − | + | 2.) Need signal cables with strain relief connects that have the shielding wrap grounded on the STB board but not grounded on the DAQ cabinet | |

| − | |||

| − | + | 3.) George will send purge covers and come back in January to install | |

| − | |||

| − | + | =January 2013= | |

| + | [[201301_R1ProgressRep]] | ||

| − | |||

| − | + | =February 2013= | |

| − | + | [[201302_R1ProgressRep]] | |

| − | + | =March 2013= | |

| − | + | [[201303_R1ProgressRep]] | |

| − | |||

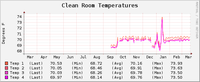

| − | + | [[File:PCR_Temps_Sept2012-March2013.png | 200 px]] | |

| − | + | =April 2013= | |

| − | [[ | + | [[201304_R1ProgressRep]] |

| + | =May 2013= | ||

| − | + | [[201305_R1ProgressRep]] | |

| − | + | =June 2013= | |

| − | [[ | + | [[201306_R1ProgressRep]] |

| + | =July 2013= | ||

| − | + | [[201307_R1ProgressRep]] | |

| − | + | =August 2013= | |

| − | = | + | [[201308_R1ProgressRep]] |

| + | =September 2013= | ||

| − | + | [[201309_R1ProgressRep]] | |

| − | |||

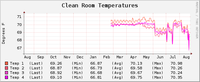

| − | + | [[File:PCR_Temps_March-Aug-2013.png | 200 px]] | |

| − | + | =October 2013= | |

| − | [[ | + | [[201310_R1ProgressRep]] |

| + | =November 2013= | ||

| − | + | [[201311_R1ProgressRep]] | |

| + | =December 2013= | ||

| − | + | [[201312_R1ProgressRep]] | |

| + | =January 2014= | ||

| − | [[ | + | [[201401_R1ProgressRep]] |

| − | |||

| − | + | ==JLab shipment== | |

| − | + | Plan: Lift chambers + Pallets out of Physics and carry them to ISU's loading dock using a fork lift on Wednesday January 8 when ISU is on Thanksgiving break. The chambers will be stored inside a heated building over thanksgiving break and be ready for pickup. | |

| − | + | Rick at Partner Steel needs to be called in December with a final date | |

| − | + | A fork lift reservation needs to be confirmed with Wade in December. | |

| − | |||

| − | |||

| − | + | [[CLAS12_R1]] | |

| − | + | =February 2014= | |

| − | [[ CLAS12_R1]] | + | [[201402_R1ProgressRep]] |

| + | =March 2014= | ||

| + | |||

| + | [[201403_R1ProgressRep]] | ||

| + | |||

| + | [[CLAS12_R1]] | ||

Latest revision as of 16:27, 7 March 2014

The Drift Chamber Wiki at JLab

1) Dial toll free, 866-740-1260 2) Enter the 7 digit Access Code, 6074391, followed by the "#" key.

or if the DAQ computer is at the IAC

service httpd start

Clean room Prep

Clean room Construction 2011

Jlab Shipment 8/8/2011

Jlab Stringing Prep

September 2011

October 2011

November 2011

December 2011

January 2012

February 2012

March 2012

ISU - Clean Room Particle Count Log

April 2012

ISU - Clean Room Particle Count Log

May 2012

June 2012

July 2012

August 2012

September 2012

JLab Shipment

October 2012

Potting

Epoxy Ratio 2.33:1 (Epon 828 Resin : Versamid 140).

November 2012

December 2012

12/3/12 Meeting Notes with Mac and George at ISU

Construction Proceedures:

Chambers outside cleanroom should have covers to keep dust off buss wires

Cap 113 (Brown one) needs to be replaced on STB board.

Need 2 amp fuse on 5 Volt supply to pre-amps.

operate chamber STB voltage at 6 Volts

Chamber grounding (ground through HV cable)

Chamber operating procedures

1.) post amplifier in VME crate had 150 mV peak-peak noise

2.) Stop using the current ADB crate

3.) New nominal Voltages from Mac are

S:F:G = 1300:-650:

S/F = 2

S/G = 5/7

Signal output doubles every 75 Volts difference between sense and field

4.) Discriminator level for signals:

5.) Need to lower the HV trip current back to 1 microA. May increase it to 5 micro Amps when burning in.

6.) Change trip speed to 0.1 sec

ISU Tasks:

1.) Install cover on top of chamber, top could be made from home insulation sheets that has been covered with paper or plastic sheeting.

2.) Install 208 Volts for ADB crates that will be sent by JLab to replace the one they have given us.

3.) solder jumpers onto HV boards, install them in January when George returns

4.) Mylar window on S1 chamber needs to have some tape and weather stripping redone or modified

5.) Get allen head 3/32 for torque wrench, remember to replace brass screws if they are removed for some reason

6.) do not do final instrumentation, purge covers, and dust covers on the last 2 chambers until checking with JLab, the may want to survey them after delivery

JLab Tasks

1.) What are the fault conditions on the STB board when the power supply exceeds voltage/current

2.) Need signal cables with strain relief connects that have the shielding wrap grounded on the STB board but not grounded on the DAQ cabinet

3.) George will send purge covers and come back in January to install

January 2013

February 2013

March 2013

April 2013

May 2013

June 2013

July 2013

August 2013

September 2013

October 2013

November 2013

December 2013

January 2014

JLab shipment

Plan: Lift chambers + Pallets out of Physics and carry them to ISU's loading dock using a fork lift on Wednesday January 8 when ISU is on Thanksgiving break. The chambers will be stored inside a heated building over thanksgiving break and be ready for pickup.

Rick at Partner Steel needs to be called in December with a final date

A fork lift reservation needs to be confirmed with Wade in December.