Difference between revisions of "CLAS12 R1"

| (63 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | [[File:08172012_TheTeam.png| 100 px]] | |

| − | |||

| − | |||

| − | |||

| + | =CLAS12_R1_Progress_Reports= | ||

| + | |||

| + | PR: | ||

| + | |||

| + | A particle detector build by ISU was successfully commissioned last month at the Department of Energy's Jefferson Lab facility in Newport News, Va. | ||

| + | |||

| + | |||

| + | |||

| + | [[CLAS12_R1_Progress_Reports]] | ||

=Time line= | =Time line= | ||

| Line 59: | Line 65: | ||

| 36 || Dec. 12, 2011 || ||Hire and begin training 2nd stringing team | | 36 || Dec. 12, 2011 || ||Hire and begin training 2nd stringing team | ||

|- | |- | ||

| − | | 40 || Jan. 9, 2012 ||March 20, 2012 ||[https://wiki.iac.isu.edu/index.php/201203_R1ProgressRep#3.2F20.2F12 Begin stringing R1 Chamber 3] | + | | 40 || Jan. 9, 2012 ||March 20, 2012 ||[https://wiki.iac.isu.edu/index.php/201203_R1ProgressRep#3.2F20.2F12 Begin stringing R1 Chamber 3 S6] |

|- | |- | ||

| || March 2, 2012|| Jan. 23, 2012 || [https://wiki.iac.isu.edu/index.php/201201_R1ProgressRep#1.2F23.2F12 Complete stringing R1 C2 Sector 1] | | || March 2, 2012|| Jan. 23, 2012 || [https://wiki.iac.isu.edu/index.php/201201_R1ProgressRep#1.2F23.2F12 Complete stringing R1 C2 Sector 1] | ||

|- | |- | ||

| − | | || March 14, 2012|| ||Begin stringing R1 C4 Sector 5 | + | | || March 14, 2012|| April 30, 2012 ||[https://wiki.iac.isu.edu/index.php/201204_R1ProgressRep#4.2F30.2F12 Begin stringing R1 C4 Sector 5] |

| + | |- | ||

| + | | 45 || March 20, 2012|| March 6, 2012 ||[https://wiki.iac.isu.edu/index.php/201203_R1ProgressRep#3.2F6.2F2012 Complete stringing and wire tests R1 C2] | ||

| + | |- | ||

| + | | || || March 31, 2012 ||[https://wiki.iac.isu.edu/index.php/201203_R1ProgressRep#3.2F31.2F12 First Signals from R1 C2] | ||

| + | |- | ||

| + | |66 ||Aug 13, 2012 || Oct. 29, 2012 || [https://wiki.iac.isu.edu/index.php/201210_R1ProgressRep#10.2F29.2F12 Complete Stringing and wire tests R1 C3 S6] dealys due to glue in feedthroughs and more complete measurements of all wire tensions | ||

|- | |- | ||

| − | | | + | | 71 || Sept 16, 2012 || Jan 7, 2013 ||[https://wiki.iac.isu.edu/index.php/201301_R1ProgressRep#01.2F07.2F13 Complete Stringing and wire tests R1 C4 S5] |

|- | |- | ||

| − | | | + | | || || Feb 19, 2013||[https://wiki.iac.isu.edu/index.php/201302_R1ProgressRep#2.2F21.2F13 Begin Stringing R1 C5 S2] |

|- | |- | ||

| − | | | + | | || ||Feb. 21, 2013||[https://wiki.iac.isu.edu/index.php/201302_R1ProgressRep#2.2F21.2F13 Begin Stringing R1 C6 S3] |

|- | |- | ||

|94 || Feb 25, 2013 || ||Complete Stringing and wire tests R1 C5 | |94 || Feb 25, 2013 || ||Complete Stringing and wire tests R1 C5 | ||

| Line 78: | Line 90: | ||

|} | |} | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| Line 187: | Line 176: | ||

| 1/6/12 || [http://www.ckgas.com/html/FM-1050-Series-Flowmeter.html Gas Flow Meter Tube E406 and HA valve] or [http://www.mathesongas.com/pdfs/products/Model-7300-&-7400-Proportioners-&-Mixers.pdf mixer AL end block Buna seals E401,E201,E910 tubes] order part # MF3-6D201-E406-E201-E910 || <math>6' \times 6' \times 1 ft^3</math>|| || || ||No | | 1/6/12 || [http://www.ckgas.com/html/FM-1050-Series-Flowmeter.html Gas Flow Meter Tube E406 and HA valve] or [http://www.mathesongas.com/pdfs/products/Model-7300-&-7400-Proportioners-&-Mixers.pdf mixer AL end block Buna seals E401,E201,E910 tubes] order part # MF3-6D201-E406-E201-E910 || <math>6' \times 6' \times 1 ft^3</math>|| || || ||No | ||

|- | |- | ||

| − | | 10/15/12 || Chain Bag || Jett chain hoist JT-101706 Call Eric at 232-8302 (Industrial Tool & Supply) || || || || | + | | 10/15/12 || Chain Bag [[http://www.bairstow.com/product/1-chain-hoist-bag-8x8x12-937.cfm chain bag]] || Jett chain hoist JT-101706 Call Eric at 232-8302 (Industrial Tool & Supply) || || || || |

|} | |} | ||

| Line 206: | Line 195: | ||

| Ordered 2 bags 4"x4" || Lint free clean room wipes ||4000 || || http://www.valutek.com/Cleanroom-Wipers/Cleanroom-Non-Woven-Wipers_2 | | Ordered 2 bags 4"x4" || Lint free clean room wipes ||4000 || || http://www.valutek.com/Cleanroom-Wipers/Cleanroom-Non-Woven-Wipers_2 | ||

|- | |- | ||

| − | | Yes | + | | Yes || tacky mats 18" x 36" ||1800 || || https://www.americanfloormats.com/clean-room-sticky-mats/ |

|- | |- | ||

| Yes(5) || get handle and head 18" tacky roller with replacement heads (3" core) ||500 || || http://www.cleanroomworld.com/category/index.cfm?cid=153&lvl=3 (no 3" replacement heads?) | | Yes(5) || get handle and head 18" tacky roller with replacement heads (3" core) ||500 || || http://www.cleanroomworld.com/category/index.cfm?cid=153&lvl=3 (no 3" replacement heads?) | ||

| Line 212: | Line 201: | ||

| Yes || glue applicator syringe ||400 || || Weller A10LL Air Operated Luer Lok Tip Syringes, 10CC, 15/Pkg | | Yes || glue applicator syringe ||400 || || Weller A10LL Air Operated Luer Lok Tip Syringes, 10CC, 15/Pkg | ||

|- | |- | ||

| − | | Yes || glue applicator needle || | + | | Yes || glue applicator needle || || || Grainger 18 and 20 GA with 1 inch cannula (Item #15VZV5 and #5FVH8) |

|- | |- | ||

| Yes || 1mm box chain || ? || || http://www.walmart.com/ip/1mm-Sterling-Silver-Diagonal-Box-Cut-Italian-Chain-Necklace-16/14892573 | | Yes || 1mm box chain || ? || || http://www.walmart.com/ip/1mm-Sterling-Silver-Diagonal-Box-Cut-Italian-Chain-Necklace-16/14892573 | ||

| Line 226: | Line 215: | ||

|- | |- | ||

| Yes || Foam Rubber Gasket || ? || || http://www.mcmaster.com/#93625k54/=eqcihp | | Yes || Foam Rubber Gasket || ? || || http://www.mcmaster.com/#93625k54/=eqcihp | ||

| + | |- | ||

| + | | yes || plastic plugs for feedthrough crimppin boots || ? || || Value Plastics, part #PIP210-2, http://www.valueplastics.com, 970-267-5200 | ||

|- | |- | ||

| ? || HVTB -> ADB Round-to-Flat Signal Cable || ? || 252.23 + S&H || Mouser | | ? || HVTB -> ADB Round-to-Flat Signal Cable || ? || 252.23 + S&H || Mouser | ||

| Line 233: | Line 224: | ||

<br /> Manufacturer: Amphenol Spectra-Strip | <br /> Manufacturer: Amphenol Spectra-Strip | ||

|- | |- | ||

| − | + | | Yes || Stringing needles (44 thousands or 1.1 mm in diameter) || || || | |

| + | |- | ||

| + | | 2/28/13 || Scissor lift replacement battery (90 Ah, (L:W:H=30.5:16.5:19.5 cm)[http://global.rakuten.com/en/store/aida-sangyo/item/10002454/?s-id=borderless_recommend_item_en] | ||

| + | || || || || || | ||

|} | |} | ||

| − | + | =CLAS 10,000= | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Definition | Definition | ||

| Line 308: | Line 284: | ||

[[Clean_Room_Particle_Counter_User_Directions]] | [[Clean_Room_Particle_Counter_User_Directions]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==Environmental control needed== | ==Environmental control needed== | ||

| Line 435: | Line 304: | ||

http://hal.iac.isu.edu/cacti-graphs/graph_6.html | http://hal.iac.isu.edu/cacti-graphs/graph_6.html | ||

| − | + | IP address of the above nagios monitor server known as hal is : | |

| + | :134.50.3.3 | ||

| − | + | From daq3 you can get to the hal VPN server using the SSH command | |

| − | + | ssh -Y -L 5900:localhost:5900 foretony@134.50.3.3 | |

| − | + | ===Sept 11 power outage recovery=== | |

| − | |||

| − | [[File: | + | [[File:HVAC_TempLog_9-11-11.png | 200 px]] |

| − | + | ==Cleaning Procedures== | |

| − | + | =R1 Construction preparations= | |

| + | == Wire Tension== | ||

| − | + | A Helmholtz coil is used to test the wire tension | |

| − | + | CLAS6 R1 wire tension measurement technique NIM article | |

| − | + | [[File:CLAS6_DCWireTensMeasTech_1996.pdf]] | |

| − | + | Below is a write up from BaBar | |

| − | + | [[File:Device2MeasureWireTension_Covery_BaBarReportTNDC-96-39_1996.pdf]] | |

| − | [[File: | + | [[File:ODU_WireTensionMeasurements_10-2009.pdf]] |

| − | + | An excel spreadsheet to calculate fields for such coils is given at | |

| − | + | http://clasweb.jlab.org/drawings/CLAS12/DRIFT_CHAMBERS/Helmholz_calculator.xls | |

| − | + | The formula is from Physics 10X but more importantly it contains wire parameters useful for the calculation | |

| − | + | ==Construction First R1 Chamber at JLab== | |

| − | + | As measured on the spit in the JLab clean room on April 28, 2011. The narrowest part of the R1 detector was 78". A door should accomodate 78" + box. | |

| − | + | The Tip of the stringing fixture was 13' 5" high from the floor. | |

| − | |||

| − | + | {| border="1" |cellpadding="20" cellspacing="0 | |

| + | |- | ||

| + | |[[File:R1CH1_4-28-2011_1.jpg | 200 px]] || [[File:R1CH1_4-28-2011_2.jpg | 200 px]] | ||

| + | |- | ||

| + | |[[File:R1CH1_4-28-2011_3.jpg | 200 px]] || [[File:R1CH1_4-28-2011_4.jpg | 200 px]] | ||

| + | |- | ||

| + | |[[File:R1CH1_4-28-2011_5.jpg | 200 px]] || [[File:R1CH1_4-28-2011_6.jpg | 200 px]] | ||

| + | |} | ||

| − | + | =CLAS12 R1 SOW= | |

| − | [[ | + | [[CLAS12_R1_SOW]] |

| − | |||

| − | + | =Readiness Review= | |

| − | + | [[CLAS12R1ReadinessReview2011]] | |

| − | + | =Region 1 Q &A = | |

| − | + | The voltage ratio should be S:F:G=2:1:5/7 (1500:-750:535). | |

| − | + | ==Wire quality== | |

| − | + | The visual inspection of the drift chamber wires after stringing led to the discovery of a variation of the wire appearance. There isn't a clear indication if this variation has an impact on the wire quality | |

| − | + | [[CLAS12R1_WireQualPic]] | |

| − | + | ==Particle Counter== | |

| + | [[File:PartCounter_Cert_112912.pdf]] | ||

| − | == | + | ==Cosmic Test Stand== |

| − | [[ | + | [[CLAS12R1_CosmicTestStand]] |

| − | |||

| − | = | + | ==ADB crate== |

| − | + | [[ADBcrate_CLAS12]] | |

| − | + | ==R1S1== | |

| − | + | [[CLAS12_R1_S1_QA]] | |

| − | + | ==R1S2== | |

| − | + | [[CLAS12_R1_S2_QA]] | |

| − | + | ==R1S3== | |

| − | [[ | + | [[CLAS12_R1_S3_QA]] |

| − | |||

| − | |||

| − | + | ==R1S5== | |

| − | + | [[CLAS12_R1_S5_QA]] | |

| − | == | + | ==R1S6== |

| + | [[CLAS12_R1_S6_QA]] | ||

| + | = Vendors= | ||

| − | + | http://www.cleanairproducts.com/ | |

| − | + | ==Shipping== | |

| − | |||

| − | + | Navis | |

| − | + | http://www.gonavis.com/about/ut1032 | |

| − | + | Artech | |

| − | + | http://artechseattle.com | |

| + | Artex | ||

| − | + | http://www.artexfas.com/services/ | |

| − | + | Fed Ex white glove | |

| − | + | http://customcritical.fedex.com/us/services/white-glove/default.shtml | |

| − | + | US art | |

| − | + | http://www.usart.com/Pages/Home.html | |

| − | + | Atelier 4 (trucks are 92" wide x 120 " long x 98") | |

| − | + | climate controlled trailer exclusive shipping | |

| − | + | http://www.atelier4.com | |

| − | + | http://www.atelier4.com | |

| − | + | =References= | |

| + | ==CLAS6 NIM Drift Chamber paper== | ||

| + | [[File:NIM_A_449_2000_pg81.pdf]] | ||

| + | ==[[CLAS12_R1_Prototype_2-20-08]]== | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==JLab Drawing repository== | ==JLab Drawing repository== | ||

| Line 635: | Line 489: | ||

http://clasweb.jlab.org/drawings/CLAS12/DRIFT_CHAMBERS/R1_End_Plate_Assembly_Procedure_RevA.doc | http://clasweb.jlab.org/drawings/CLAS12/DRIFT_CHAMBERS/R1_End_Plate_Assembly_Procedure_RevA.doc | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | ==Project factoids== | ||

| − | [[ | + | [[CLAS12DC_ProjFactoids]] |

| + | [[Old_CLAS12]] | ||

[http://wiki.iac.isu.edu/index.php/Hall_B] Go Back to [[Hall_B]] | [http://wiki.iac.isu.edu/index.php/Hall_B] Go Back to [[Hall_B]] | ||

Latest revision as of 22:29, 27 February 2017

CLAS12_R1_Progress_Reports

PR:

A particle detector build by ISU was successfully commissioned last month at the Department of Energy's Jefferson Lab facility in Newport News, Va.

Time line

Time needed to train lead stringer at JLab = 4-6 weeks?

| Start Date | End Date | Actually End Date | Description |

| 5/17/10 | 9/30/10 | 8/6/10 | Sign MOU |

| 5/17/10 | 9/30/11 | 4/12/11 | Contract recieved |

| 8/3/2010 | 8/3/2010 | 8/18/2011 | Readiness Review |

| 9/1/10 | 10/29/10 | 6/16/2011 | Hire and train R1 Lead Stringer |

| 10/1/10 | 2/28/11 | Hire and train 2 R1 stringers | |

| 11/16/09 | 11/30/10 | Build R1 Cleanroom | |

| 11/5/2010 | 11/12/2011 | 8/16/2011 | Ship 1st R1 Box From JLab to ISU |

| 12/17/2010 | 2/28/2011 | String First R1 Chambers | |

| 2/21/2011 | 3/31/2011 | Ship remaining R1 Boxes From JLab to ISU | |

| 3/31/2011 | 1/25/2012 | Fixture and 2 chambers arrive at ISU | |

| 7/13/12 | Complete 6th R1 chamber | ||

| 4/5/13 | 9/30/13 | Ship chambers, fixtures, platforms and crane to JLab |

| Week | Expected Date | Actual Date | Description |

| 0 | April 4, 2011 | 4/12/11 | Issue Construction contract |

| 4 | May 2,2011 | 6/13/11 | Hire lead stringer send to JLab for training |

| 14 | July 11, 2011 | August 18, 2011 | Clean room installed at ISU, Readiness Review, Hire 1st stringing team |

| Sept. 26, 2011 | Begin stringing R1 chamber 2 | ||

| Nov, 2011 | Dec. 2, 2011 | Finish guard and field wires on Region 1 Chamber 2 | |

| 36 | Dec. 12, 2011 | Hire and begin training 2nd stringing team | |

| 40 | Jan. 9, 2012 | March 20, 2012 | Begin stringing R1 Chamber 3 S6 |

| March 2, 2012 | Jan. 23, 2012 | Complete stringing R1 C2 Sector 1 | |

| March 14, 2012 | April 30, 2012 | Begin stringing R1 C4 Sector 5 | |

| 45 | March 20, 2012 | March 6, 2012 | Complete stringing and wire tests R1 C2 |

| March 31, 2012 | First Signals from R1 C2 | ||

| 66 | Aug 13, 2012 | Oct. 29, 2012 | Complete Stringing and wire tests R1 C3 S6 dealys due to glue in feedthroughs and more complete measurements of all wire tensions |

| 71 | Sept 16, 2012 | Jan 7, 2013 | Complete Stringing and wire tests R1 C4 S5 |

| Feb 19, 2013 | Begin Stringing R1 C5 S2 | ||

| Feb. 21, 2013 | Begin Stringing R1 C6 S3 | ||

| 94 | Feb 25, 2013 | Complete Stringing and wire tests R1 C5 | |

| 97 | March 18, 2013 | Complete Stringing and wire tests R1 C6 | |

| 104 | April 27, 2013 | November, 2014 | Ship chambers, fixtures, platforms and crane to JLab |

| Items From JLab |

| $2,500 Crane to mount DC (use grant to buy) |

| (Done) comes with stringing fixtures!. platform to take chamber from upper level to lower |

| JLab will order 2 Man Lifts to reach 15' |

| Primary magnets for wire tension measurements will be sent by JLab (We have budgeted for power supply get one that is 15 V, 100 amp Analog better than switching) |

Task list

Secure strip doorDrill holes and Mount braces for seismic....geo....something requirements- Make door for storage area under stairs

Get 480 V outlets installed - Currently in progress. Estimated completion date: September 23, 2011.- Order changing room items (bench, storage rack for clothes)

Fix vinyl wall around fixture (need to install snaps)Mount power supply under fixture. Attach coil wires to power supplies (terminal ends for 1 gauge wire? maybe from an automotive store for battery cables)- Find/build tray for manlift (1-2 feet wide , 6 inches deep) - Grainger part number: 2NXN5.

Test stringing machine- Door for entrance to clean room

Cordless phone for cleanroom (call telecommunications 4541, 4900) Beam lab #2631Build adjustable pulley for bottom stringerBuild chain weights for stringingBuild tension weights- Order torque wrench (in*lbs) – contact Steve Christo for part number. More than likely this is an expensive item, might cost $200-300 from Snap-On...maybe

Order several power strips (min 3) - may need extension cords also- Hard door for changing room

Order

Scale - prefer digital that can measure to 1/10th gram. I put a link on the wiki page but I'm sure we can find this locallyDremel engraving bit- Order snap fasteners ~100

Purchasing

Things we need to buy and when they need to be here

Equipment

| Arrival Date | Item to Purchase | Sample Item | Lead Time | Budget | Cost | Done |

| 6/10/11 | Get Shipping Company for Clean room (??? Weight and Dimensions) | quote from CleanAirQuote from shipper | 1925 | Yes | ||

| 6/13/11 | Get Mobile Crane Company for Clean room Unloading | 1-2 days | ? | Yes | ||

| 6/20/11 | $2,500 Crane to mount DC (use grant to buy) | Arnold Machinery | 7-10 days | 2882 | Yes | |

| 6/20/11 | Crane chain and chain hoists (use grant to buy) | Empire Machinery | 7-10 days | 1155 | Yes | |

| 8/1/11 | Clean room Quality worktable ( ?? Quantity & Size) | Stainless Steel Top Item 1521-55 | 1530 | 1198 | Yes | |

| 8/1/11 | 2 Clean room Quality Storage Cabinet | Acrylic Storage Cabinets 9011-07 | 2800 | 911x2 | Yes | |

| 8/1/11 | 2 Clean room Quality Utility carts | Utility Carts 1401-46 | 1200 | 599x2 | Yes | |

| 8/1/11 | 4 Clean room Quality chairs | Ergonomic Lab Chairs 2801-02 | 1 week | 1000 | 366x4 | Yes |

| 8/1/11 | 1 Clean room Quality tool chest | Craftsman 41" 11-Drawer SS Toolbox | 1000 | 600 | Yes | |

| 8/1/11 | 1 Clean room Quality and fire safe trash containers and bags | Stainless Steel 24Gallon 1456-03 | 1 week | 1000 | 550 | Yes (need more bags) |

| 8/1/11 | Primary magnets power suppllies 40 V, 100 amp Analog better than switching | Model REK 45-78 $8k | 3000 | Yes | ||

| 8/1/11 | Clean room Particle Counter | Kanomax 3887 Handheld Laser Particle Counter. 0.3 - 5.0 microns, 3 Channels, 0.1 CFM. | 3 days | 2000 | 1875 | Yes |

| 8/1/11 | CAEN N1471 | http://www.caen.it/csite/CaenProd.jsp?showLicence=false&parent=1&idmod=622 | 6000 | 5,932 | Yes | |

| 8/27/11 | Bench Scale | http://www.gramscales.com/product_info.php?cPath=25&products_id=338 | 1 week | ? | 45 | Yes |

| 1/6/12 | [1] Bubbler [2] or [3] or [4] | 10 days | ordered Jan 4 | |||

| 1/6/12 | Gas Flow Meter Tube E406 and HA valve or mixer AL end block Buna seals E401,E201,E910 tubes order part # MF3-6D201-E406-E201-E910 | No | ||||

| 10/15/12 | Chain Bag [chain bag] | Jett chain hoist JT-101706 Call Eric at 232-8302 (Industrial Tool & Supply) |

Consumables

| Need to Order? | Item to Purchase | Budget | Cost | Vendor | ||

| No | Frocks | 3000 | www.wenvy.com, part number 21-639-S,M,L,XL | |||

| No | Shoe cover | 1000 | Grainger From Norco its part #ENVV3100-UNIV (1 case of 150 , $0.19 each) (LDS account Z8342) | |||

| No | head covers | 1000 | 4953-85 | |||

| Yes | nitrile gloves (L, M) | 27000 | XLarge Large Medium small | |||

| Ordered 2 bags 4"x4" | Lint free clean room wipes | 4000 | http://www.valutek.com/Cleanroom-Wipers/Cleanroom-Non-Woven-Wipers_2 | |||

| Yes | tacky mats 18" x 36" | 1800 | https://www.americanfloormats.com/clean-room-sticky-mats/ | |||

| Yes(5) | get handle and head 18" tacky roller with replacement heads (3" core) | 500 | http://www.cleanroomworld.com/category/index.cfm?cid=153&lvl=3 (no 3" replacement heads?) | |||

| Yes | glue applicator syringe | 400 | Weller A10LL Air Operated Luer Lok Tip Syringes, 10CC, 15/Pkg | |||

| Yes | glue applicator needle | Grainger 18 and 20 GA with 1 inch cannula (Item #15VZV5 and #5FVH8) | ||||

| Yes | 1mm box chain | ? | http://www.walmart.com/ip/1mm-Sterling-Silver-Diagonal-Box-Cut-Italian-Chain-Necklace-16/14892573 | |||

| Yes | Epon 829 Resin (3 year shelf life) | 1300 | E.V. Roberts, 18027 Bishop Avenue, Carson, CA 90746-4019, United States, Phone +1 310-204-6159, Toll Free: +1 800-374-3872, Fax: +1 310-202-7247, http://www.evroberts.com/ | |||

| Yes | Versamid 140 Hardener (?? shelf life) | 800 | ||||

| Yes | Staticide - anti-static cleaner | ? | http://www.aclstaticide.com/01/index.html | |||

| Yes | 0.001" Aluminized Mylar | 2640 | 150 ft Sheldahl Inc at 1-507-663-8000, part# 146468 (width of 48") | |||

| Yes | Foam Rubber Gasket | ? | http://www.mcmaster.com/#93625k54/=eqcihp | |||

| yes | plastic plugs for feedthrough crimppin boots | ? | Value Plastics, part #PIP210-2, http://www.valueplastics.com, 970-267-5200 | |||

| ? | HVTB -> ADB Round-to-Flat Signal Cable | ? | 252.23 + S&H | Mouser

| ||

| Yes | Stringing needles (44 thousands or 1.1 mm in diameter) | |||||

| 2/28/13 | Scissor lift replacement battery (90 Ah, (L:W:H=30.5:16.5:19.5 cm)[5] |

CLAS 10,000

Definition

| Class | maximum particles/m³ | FED STD 209E equivalent | |||||

|---|---|---|---|---|---|---|---|

| ≥0.1 µm | ≥0.2 µm | ≥0.3 µm | ≥0.5 µm | ≥1 µm | ≥5 µm | ||

| ISO 7 | 352,000 | 83,200 | 2,930 | Class 10,000 | |||

| ISO 9 | 35,200,000 | 8,320,000 | 293,000 | Room air | |||

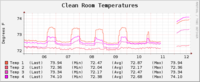

ISU Clean room Environment monitors

Temperature

Temp1 == Top of clean room middle.

Temp2 == South wall bottom

Temp3 == South wall top

http://hal.iac.isu.edu/cacti-graphs/graph_6.html

The ISU clean rooom is 20' x 21' x 15' = 6300 ft^3 = 178 m^3

PhysicsCleanRoomParticleCountLog

Clean_Room_Particle_Counter_User_Directions

Environmental control needed

Temperature control constraint is

The wire tension can fluctuate no more than 5% from the mean wire tension specification.

This means that the temperature should be controlled to within +/- 2 Degrees Ferenheit

Humidity control: 55 % or less

File:KashyHallBTempReport 2-09.docFile:KashyHallBTempReport 2-09.pdf

Online Room Temp monitors

http://hal.iac.isu.edu/cacti-graphs/graph_6.html

IP address of the above nagios monitor server known as hal is :

- 134.50.3.3

From daq3 you can get to the hal VPN server using the SSH command

ssh -Y -L 5900:localhost:5900 foretony@134.50.3.3

Sept 11 power outage recovery

Cleaning Procedures

R1 Construction preparations

Wire Tension

A Helmholtz coil is used to test the wire tension

CLAS6 R1 wire tension measurement technique NIM article

File:CLAS6 DCWireTensMeasTech 1996.pdf

Below is a write up from BaBar

File:Device2MeasureWireTension Covery BaBarReportTNDC-96-39 1996.pdf

File:ODU WireTensionMeasurements 10-2009.pdf

An excel spreadsheet to calculate fields for such coils is given at

http://clasweb.jlab.org/drawings/CLAS12/DRIFT_CHAMBERS/Helmholz_calculator.xls

The formula is from Physics 10X but more importantly it contains wire parameters useful for the calculation

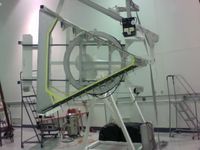

Construction First R1 Chamber at JLab

As measured on the spit in the JLab clean room on April 28, 2011. The narrowest part of the R1 detector was 78". A door should accomodate 78" + box.

The Tip of the stringing fixture was 13' 5" high from the floor.

|

|

|

|

|

|

CLAS12 R1 SOW

Readiness Review

Region 1 Q &A

The voltage ratio should be S:F:G=2:1:5/7 (1500:-750:535).

Wire quality

The visual inspection of the drift chamber wires after stringing led to the discovery of a variation of the wire appearance. There isn't a clear indication if this variation has an impact on the wire quality

Particle Counter

File:PartCounter Cert 112912.pdf

Cosmic Test Stand

ADB crate

R1S1

R1S2

R1S3

R1S5

R1S6

Vendors

http://www.cleanairproducts.com/

Shipping

Navis

http://www.gonavis.com/about/ut1032

Artech

Artex

http://www.artexfas.com/services/

Fed Ex white glove

http://customcritical.fedex.com/us/services/white-glove/default.shtml

US art

http://www.usart.com/Pages/Home.html

Atelier 4 (trucks are 92" wide x 120 " long x 98")

climate controlled trailer exclusive shipping

References

CLAS6 NIM Drift Chamber paper

CLAS12_R1_Prototype_2-20-08

JLab Drawing repository

https://userweb.jlab.org/~aellis/R1_Fixture/

R1 Fixture Procedures

File:CLAS12 R1 FixturProcedures.doc

Referenced drawings

File:Sheet1 B00000-07-04-3200.pdfFile:Sheet2 B00000-07-04-3200.pdfFile:Sheet3 B00000-07-04-3200.pdf

Stringing Manual

Stringing Manual

Media:R1_CLAS12_StringingManual_2008.doc Media:R1_CLAS12_StringingManual_2008.pdf

File:2012CLAS12R1AmmendedStringingManual.pdf

Gas flow operation

Standard operating pressure is 0.05" inches of water.

the bubbler exhaust tip should barely touch the oil enough to cause bubbles.

http://clasweb.jlab.org/drawings/CLAS12/DRIFT_CHAMBERS/R1_Chamber_Assembly_Procedure.doc

http://clasweb.jlab.org/drawings/CLAS12/DRIFT_CHAMBERS/R1_End_Plate_Assembly_Procedure_RevA.doc