Mini-prototype

Drift Chamber prototypes were constructed to evaluate drift chamber designs for CLAS12.

Run Plan for Mini-prototype Performance Measurements

Description of General Operation

Chamber Ionization Gas

Our initial plan will be to use (75/25) flowing though the chamber at a flow rate high enough to exchange the volume once a day.

high Voltage supply

A CAEN 4 channel high voltage supply (N470) will be used to supply HV to the drift chambers. The supply is capable of monitoring currents at the microAmp(A) level and voltages at the Volt (V) level.

An e-mail from Mac has suggested we run the chamber such that the voltage difference between the sense and field wire be about 2490 Volts. He suggests sense:field:guard voltages of 1660:-830:830 respectively as a starting point and recommends keeping the ratio 2:-1:1 in order to have equal gain among the sense wires.

Signal Processing

Each sense wire is capacitively coupled to a preamplifier by a 221 pF capacitor. A schematic of the preamplifier (CP01H1- Hybrid) is shown below.

File:MiniProtoDC PreamplifierCircuit.pdf

File:MiniProtoDC BFT25.pdf

File:MiniProtoDC BFT92.pdf

a signal translator board was designed to power the 7 preamplifiers for each sense wire. A negative voltage regulator (Fairchild part # LM7905CT File:MiniProtoDC VoltageReg LM790CT.pdf) is used to regulate the +5 voltage voltage input thereby "floating" the ground of the circuit. The layout of this board is shown below.

File:MiniProtoDC SignalTranslatorBoard.pdf

The 7 sense wire signals from the Drift Chambers signal translator board will be processed through several

NIM based modules.

One can expect to amplify the sense wire output from a factor of 10 to 30 times. We will use our

Ortec amplifier to amplify the

sense wire output by a factor of 10.

A descriminator from Lecroy with a threshold range from 30 mV up to 1.5 Volts will be used to create a stop pulse for TDCs

that are started by scintillators which detect either an electron, during tests at the IAC, or cosmic rays, during tests at the LDS (see below). Hall B has loaned the ISU group a

TDC module for the drift chamber studies. Pulse height studies may also be done using an ADC. The DAQ system to manage the signal processing electronics is described below.

DAQ System

The DAQ system is described here

Cosmic tests

Apparatus

Place chamber between two plastic scintillator paddles to check signals. We will use the large area 7 cm by 50 cm paddles with the Russian PMTs operating at 1300 V and threshold > 150 mV to select energetic cosmic rays. We will arrange the paddles so that they are perpendicular to one another. From above, the paddles will have 7 cm by 7 cm overlap. This will allow for testing the chamber along its length.

scope pulses

We will insert oscilloscope pictures of the Drift Chamber output signals we observe.

Planned tests

We will use the scintillator paddles to detect cosmic rays and perform the following tests:

1. Efficiency along length of chamber with overlapping array of scint. paddles optimized for normal incidence.

2. Efficiency as a function of discriminator threshold, i.e. what is the required energy of the cosmic ray.

3. Efficiency as a function of angle. Count rates will decrease so we will have to determine the best overlapping configuration of the paddles.

4. Noise Rates. Generate a delayed OR gate from the two cosmic ray detectors in order to measure noise in the baby chamber. Record pulse heights on all wires + scintillators.

The above tests will give us a baseline for the drift chamber and are not designed to evaluate the efficiency as a function of distance from the endplate due to the large angular divergence of the incident cosmic rays and the limited counting statistics. We will use a finely collimated secondary electron beam at the IAC in order to make precision measurements of the efficiency as a function the ionization event distance from the endplate.

Electron test facility

IAC 25 MeV electron accelerator

The Idaho Accelerator Center (IAC) operates a 25 MeV Linac capable of delivering instantaneous electron currents of 80 mA/pulse. Pulse widths range from 80 ns to 2 s and repetition rates from single shot to 1 kHz. Drift Chamber testing will use this accelerator to create a secondary electron beam as described below.

secondary electron beam setup

We will need to bring the electron beam from Accelerator lab #1 to the experimental testing cell labeled as "target room" .

Floor Plan of IAC.

Floor Plan of IAC.

An evacuated beam pipe from the current exit window of the LINAC to the collimator entrance at the wall will be built to accomplish this. Magnetic elements are already in place to stear electrons into the "target room". The pipe will have aluminum windows at either end to allow for passage of the electron beam. Phil will be responsible for the design and safety concerns of implementing the pipe. The wall is 6' thick, which is 4' of packed earth sandwiched between 1' of concrete on either side. Upon reaching the wall the electron beam will travel through the hole defined by the collimator aperture. The electron beam will have to travel through a distance of 8' of air as it goes into the experimental test cell. The radiation length of air at STP is over 300 m, so this ought not be a problem. We can place an insert into the collimator on the test cell side to define the electron beam if need be.

We will use Dan's idea of elastic scattering. See: http://www.physics.isu.edu/~cole/IAC/DC_prototype/Detector-Test.pdf

The idea: the beam is incident upon a pencil lead target and the electrons will elastically scatter off the carbon atoms. The prototype will be positioned perpendicular to the incident electron beam so that only the elastically scattered electrons will pass through the chamber. We will place 5 mm by 5 mm scintillators on either side of the chamber. This scintillator arrangement allows for triggering and defining the beam. The paddles will be fixed and the prototype will be on a moveable platform that will be controlled by a stepper motor. This will allow us to measure the sense wire efficiency along the length of the wire and, in particular, the efficiency in close proximity to the feedthroughs.

Description of how beam size will be measured or why it isn't needed.

stepper device

I think the device below can be used to move the minichamber across the backscattered electron beam. The device is over 3 feet in length and has a platform with is 6" x 6". We should configure the platform so it can hold both chambers "back-to-back" in order to test both chambers at the same time. The first chamber has four 3/8" bolts on the bottom for mounting but the 2nd one has yet to have anything.

Drift Chamber efficiency measurements

Efficiency -vs- Distance

The secondary electron beam will be moved towards the drift chamber endplate while the efficiency is measured. The results of our tests will be placed below.

| Distance | Feedthrough Efficiency | |

| (mm) | plastic | metal |

| 2 | ||

| 4 | ||

| 6 | ||

| 8 | ||

| 10 | ||

| 12 | ||

| 14 | ||

Metal feedthrough

Radiation Tests on Gas

Place chamber in main hall and direct high current electrons through the prototype.

1. Do not flush gas. How long does it take before the efficiency detiorates due to radiation damage of the gas.

2. Flush gas at variable rates to determine what the minimum flush rate is to ascertain proper stable efficiency.

Measurements in LDS

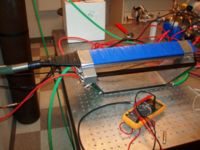

HV connections and Readout

The High Voltage lines are shown below along with labels for the three voltages. I will try to install SHV connectors as well as a plastic safety shield to keep a student's finger away from the HV.

After Installing SHV BNC connectors

Preamp power connector inputs

Output connector. Preamp output signals are differential.

Inspecting Detector Signals

The sense wire drift chamber output was monitored to search for ionization events from cosmic rays. A scintillator paddle was place on top of the detector in order to create a scope trigger which would indicate the passage of a charged particle.

The link below describes scope measurements taken in the LDS

MiniDC_Signals_10-0-07

MiniDC_Signals_4-22-08

MiniDC_Signals_4-25-08

Preamp Output

The preamplifiers described above are capacitively connected to the sense wires using the custom built signal translator board. I applied 5.7 to 6.0 Volts to the board based on observations using a test pulses input to the signal board. Under operating conditions a RC like feedback noise with an MHz frequency and 50 mV amplitude was observed as the voltage to the preamp board is increased from about 2.8 volts to 5.5 volts. The link below documents our observations.

The next step will be to setup the DAQ system to perform to measure the sense wire outputs. I will use the cosmic telescope to generate a trigger pulse when cosmic rays pass through the drift chamber. When we install the system up at the IAC the beam RF will be used as the trigger.

Determining Min operating HV

The output of all seven sense wires was measured using a scope in order to identify the high voltage settings to be used when operating the drift chamber.

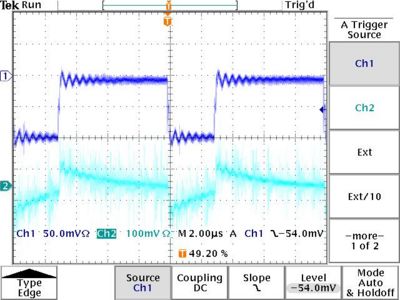

Post Amp NIM Module

The DC preamp output is sent to a translator board in a NIM bin module. The translator board takes the differential preamplifier output as input and outputs a single ended pulse through the front panel lemo connectors. A 100 mV negative test pulse was injected into the preamplifier board and sent to all preamp channels. The output of the translator board was looked at on a scope and compared to the preamp input pulse. The image below shows the input pulse to the drift chamber preamp circuit via the lemo input on the top trace and the translator output on the bottom trace. All signals were terminated in 50 Ohms on the scope.

Metalica_TestPulseoutput_12-20-07

Metalica_TestPulseoutput_12-21-07

CAEN V792 ADC calibration

MiniPrototype_CAEN_V792_Calibration

Cosmic runs

MiniPrototype_CosmicRuns

MiniPrototype_SinglesCosmicRuns_2008

MiniPrototype_CoincidenceCosmicRuns_2008

MiniPrototype_Operation_Regions_2008

GEM_and_Mini_Prototype_DC_Cosmics_Run

Analysis

Programs

On the DAQ machine in the subdirectory

/home/daq/CODA/CODAreader/UsingROOTnEVIO/evio2root

there are 2 programs

evio2nt will create a ROOT tree using the CODA data file usage:

evio2nt -f/data1/rxxx.dat or for data taken on Jan 08, 2008

evio2nt -f/data1/BabyChamberEfficiency_1-08_1550SenseWires/rxxx.dat

this output a file called "rxxx" which you need to renamen to "rxxx.root" and then you can look at it.

A few commands

root[] new TBrowser();

root[] ntuple->Draw("ADC1")

root[] ntuple->Draw("ADC1","ADC1<4096")

root[] ntuple->Draw("ADC1:ADC2")

IAC Runs

HRRL runs

UV laser tests

CLAS 12 Tracking workshop 2/21/08

Design review in May 2008 with Hall D

mrad

Acceptance: 50% of 2 at 5 degree scattering angle.

30 sense wire

92/08 ArCO2

24000 wires in CLAS12 and 34000 sense wires in CLAS6

Baby chamber HV setting

Mac's e-mail from 3=20-08

I have been checking my voltage calculations for the 7-cell

chambers using GARFIELD and my own program.

For 30-micron wire, a surface electric field of 188 kV/cm should give a gain of 1*10^4 and a surface field of 204 kV/cm should give a gain of 5*10^4 for 90:10 Ar:CO2. (NOTE: for a 20-micron wire a surface field of 234 kV/cm is required for the same gain of 1*10^4.)

So if you raise your voltage by a factor 204/188 = 1.085; you'll change the gain by a factor of 5.

The voltages required to get to these surface field depends on the cell geometry (7-cell, or regular superlayer), on the size (8 mm cell, 2 cm cell, etc.) and on the radius of the field wire (70 micron, 140 microns, etc.) The cell capacitance changes with field wire diameter and so the required voltage difference to get the same surface charge on the sense wire changes. To keep gain constant while you're changing the field wire diameter you have to decrease the voltage for a larger field wire. The voltage factor for field wire diameter (normalized to 50 micron field wire) is 1:0.983:0.966:0.949 for 50,70,100 and 140 micron field wire.

To keep the surface field and thus the gain constant on ALL of the sense wires, requires a certain ratio of sense to field to guard wire voltages. For a regular superlayer this ratio is 1:-0.5:0.36; for example, 1500,-750,535 for our present r3 chambers. For a 7-cell chamber there is a much bigger "perimeter" and the guard wire voltage has to be raised. Here the ratio is 1:-0.5,0.7.

So, now you know how to scale for various changes. That said Vs,f,g of 1530,-765,1065 gives a gain of 1*10^4 for a 7-cell chamber with 30 micron sense wire and 70 micron field wire and 140 micron guard wire and an 8mm sense to field wire distance; in other words, "BABY"!!

If your "baby" has 140 micron field wire, then scale the voltages by 0.949/0.983.

If you want to raise the gain to 5*10^4 then scale the voltages

I have been checking my voltage calculations for the 7-cell chambers using GARFIELD and my own program.

For 30-micron wire, a surface electric field of 188 kV/cm should give a gain of 1*10^4 and a surface field of 204 kV/cm should give a gain of 5*10^4 for 90:10 Ar:CO2. (NOTE: for a 20-micron wire a surface field of 234 kV/cm is required for the same gain of 1*10^4.)

So if you raise your voltage by a factor 204/188 = 1.085; you'll change the gain by a factor of 5.

The voltages required to get to these surface field depends on the cell geometry (7-cell, or regular superlayer), on the size (8 mm cell, 2 cm cell, etc.) and on the radius of the field wire (70 micron, 140 microns, etc.) The cell capacitance changes with field wire diameter and so the required voltage difference to get the same surface charge on the sense wire changes. To keep gain constant while you're changing the field wire diameter you have to decrease the voltage for a larger field wire. The voltage factor for field wire diameter (normalized to 50 micron field wire) is 1:0.983:0.966:0.949 for 50,70,100 and 140 micron field wire.

To keep the surface field and thus the gain constant on ALL of the sense wires, requires a certain ratio of sense to field to guard wire voltages. For a regular superlayer this ratio is 1:-0.5:0.36; for example, 1500,-750,535 for our present r3 chambers. For a 7-cell chamber there is a much bigger "perimeter" and the guard wire voltage has to be raised. Here the ratio is 1:-0.5,0.7.

So, now you know how to scale for various changes. That said Vs,f,g of 1530,-765,1065 gives a gain of 1*10^4 for a 7-cell chamber with 30 micron sense wire and 70 micron field wire and 140 micron guard wire and an 8mm sense to field wire distance; in other words, "BABY"!!

If your "baby" has 140 micron field wire, then scale the voltages by 0.949/0.983.

If you want to raise the gain to 5*10^4 then scale the voltages by 204/188.

Metalica and Plastika have 30 micron sense and 140 microns field/guard wire diameters.

by 204/188.

| HV settings | ||

| Wire | Volts | current (A) |

| Sense | 1500 | |

| Field | -726 | |

| Guard | 1047 | |