Neutron TGEM Detector Abdel

Haithem's logbook for developing neutron sensitive TGEM detector

Resistive paste thickness-mass calibration curve

- Aim

Studying the relationship between the mass and thickness of the resistive paste painted over 10X10 HTTGEM Foil.

- Experiment equipments and restrictions

Accurate scale (), SEM (scanning electron microscope).

SEM sample's height limit : 5 cm.

(Dr. David Peterson Assistant Professor in Anthropology,Research Scientist, Center for Archaeology, Materials and Applied Spectroscopy (CAMAS) , 157 Graveley Hall,Idaho State University)

- Procedure

Measuring the mass of Prepared samples of 0.5 thickness FR4 square plates with different surface areas as in the table below before and after painting the paste.

Studying the paste distribution and thickness under SEM.

- Experimental Data

| Plate Surface area (cm^2) (length ) | mass (g) before applying the paste | mass (g) after applying the paste | notes | |

| 1X1 | 0.2627 | 0.2634 | 0.7 | paste on both sides |

| 2X2 | 0.9776 | 0.9793 | 0.4 | paste on both sides |

| 3X3 | 2.5074 | 2.5074 | 0 | paste on one side |

| 4X4 | 4.4923 | 4.4940 | paste on one side | |

| 5X5 | 7.3261 | 7.3250 | paste on one side (paste is not uniform) |

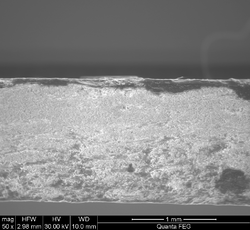

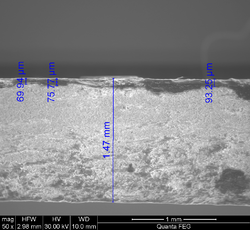

- SEM Images

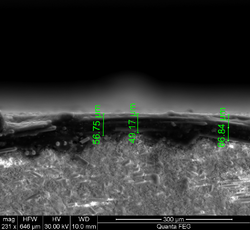

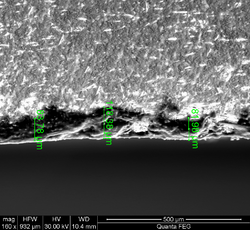

- 2x2 sample

| Image(a) | Image(b) | Image(c) | |

|

|

|

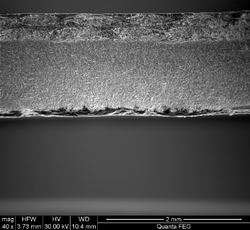

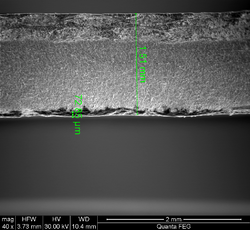

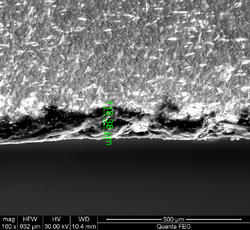

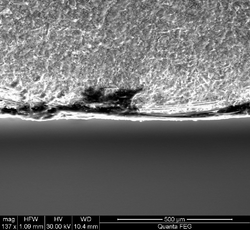

- 4x4 sample

| Image(1) | Image(2) | Image(3) | Image(4) | Image(5) |

|

|

|

|

|

- Conclusions and Next step(s)

-Using SEM is accurate enough to measure the paste thickness within few micros depending on the HFW (horixzontal field width) value (determined for each image).

- Highly recommended to use a high precision scale for measuring the mass variation accurately for each samples, not only for this experiment but also for the future samples that will contain a radioactive materials.

- Preferable size for the best image is 2x2 cm with clean edges and reference line.

- The resistive paste thickness changes from one sample to another and is not unform surface within the micrometer scale, for the 4x4 sample maxmimum value measured or the paste thickness was 120 um, and the minimum was 80 um. Successivly, the 2x2 sample paste thickness was measured with a maximum of 66.84 um and mimimum 49.17 um.

- The measurements were accurate whenever the paste is distiguished from the over flow of the paste on the edge, and as the charging on the sample is the least. (When the sample was inside the SEM-chamber, a beam of electrons hit the sample and created charged areas that soemtimes ddi not make the edge image sharp enough, this is clear by comparing image (4) and image (5)).

- New samples will be prepared, all have the 2x2 cm^2 area, with a small groove on the edge to have new images by SEM, each sample will have a cerain amount of the resistitive paste, the mass of the paste accuratlely be determined (hopefully) using a high presicion scale.

Experiment Tasks timetable

| Date | Task | Notes |

| 10/20/10 | Preparing the samples in different areas | Done on time |

| 10/21/10 | painting and curing the paste, measuring the mass before and after painting the paste | measuring the mass is accurate enough, even we borrow the scale and put it in table without anything around and without being moved just for the day of the taking the data or finding a more accurate one in a more stable measuring conditions. |

| 10/22/10 | studying the samples using SEM | CAMAS facility across Alvin Ricken Drive from the Idaho Accelerator Center, at 11:00 AM |

| 10/28/10 | studying the 2x2 samples using SEM | (postpone) CAMAS facility across Alvin Ricken Drive from the Idaho Accelerator Center, at 11:00 AM |

| 11/4/10 | studying the 2x2 samples using SEM | CAMAS facility across Alvin Ricken Drive from the Idaho Accelerator Center, at 11:00 AM ?? |

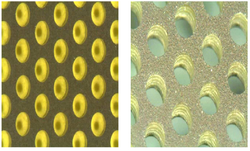

RETGEM vs. THCOBRA

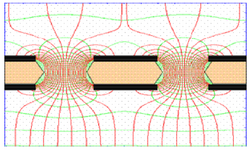

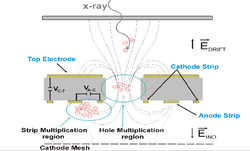

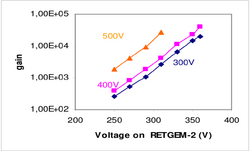

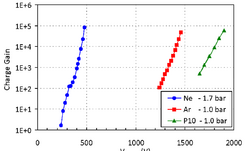

| RETGEM | THCOBRA |

|

|

|

|

|

|

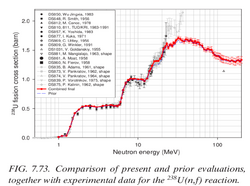

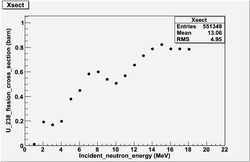

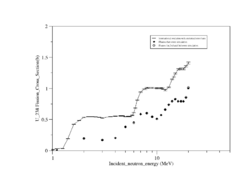

Comparison ENDF evaluation of U-238 neutron fission xsection and GEANT4

|

|

|

INTERNATIONAL EVALUATION OF NEUTRON CROSS-SECTION STANDARDS, INTERNATIONAL ATOMIC ENERGY AGENCY,VIENNA, 2007 File:U238-xsection.pdf

- absolute f_xsection in the table 7.1 p.91

| Ref. number | inxn | data description | author | citation | notes |

| 809 | 238U(n,f) | Absolute | G. Winkler et al. | 91Jülich (1991) 514 | the paper represents f_xsection ratio measurements of U_238 to Al_27, Na_24, Fe_56, Mn_56 * found in library QC770 N742 1992) |

| 810 | 238U(n,f) | Absolute | K. Merla et al. | 91Jülich (1991) 510 | * The paper represents f_xsection ratio measurements of U_238, U_235 , Np_237, and Pu_239 for 4.45 MeV, 8.46 MeV, 18.8 MeV * very accurate description for the experiment details and through the figures and the tables * found in library QC770 N742 1992) |

| 877 | 238U(n,f) | Absolute | I.M. Kuks et al. | At. Energy 30 (1971) 55 | *measured f_xsection U_238 fission for 2.5 MeV Neutrons |

| 860 | 238U(n,f) | Absolute | N.N. Flerov et al. | At. Energy 5 (1958) 657 | *title : antinutrino , Mean number of neutrons emitted in fission of U235 and U238 by 14-Mev neutrons, Mean number of neutrons emitted in fission of U235 and U238 by 14-Mev neutrons |

Done In April (edited by 04/30/10)

1.)Testing the new laminate with random holes after applying the resistive paste on both sides. Also, the trial of applying the paste was done, 0.1 inch brush is used for that to avoid covering the holes with the paste. the following procedure were taken:

a- Voltage is applied on the the foil to check the first sparking place.

b- Applying the paste carefully on the area between the holes with very small quantities.

- Result

a) Applying the paste shifts the sparking area to next neighboring one, so looks this will lead us to cover all the areas between the holes to kill the sparks.

b)A need to keep the foil under voltage to keep tracking of the sparks which lead unfortunately led to loss the voltage between the two copper layers.

Even a drop of paste got stuck in one of the holes(which has low possibility since I cleaned all the paste applied very well), or the two layers are no longer isolated from each other!

2.)Final touches on the HV-circuit are done, diagrams are done by eagle with Gerber files, the chamber is ready for redesigning.

3.)Running Th-232 fission simulation without ionization on inca and daq1. Energies 1-9MeV (inca) and 19-22 MeV(daq1) will be done by today(04/30/10).

4.)Tracking the process to get Th-232, contacting other vendors for radioactive isotopes, trying to get low cost ones.

AFCRD Reports-2011

Th-232 and U-238 Activity in mCi

General information:

| Physical properties | U-238 | Th-232 |

| Half life in years | 4.468 X 10^9 | 1.405 X 10^10 |

| Decay rate per second | 4.91 X 10^-18 | 1.56 X 10^ -18 |

| Molar Mass g/mol | 238.02891 | 232.0381 |

| Activity of 2 kg in mCi | 0.68 | 0.22 |

Avogadro's number is 6.0221 X 10^23 /mol

1 Ci = 3.7 X 10^10 disintegration/ second

References

- 2010 THGEM design(s)

File:THGEM 2009 design gas efficiency.pdf

Simulations_of_Particle_Interactions_with_Matter

Voss and 3 russian references for Dy(n,x) cross sections

Media:Shalem_MSthesis_march2005.pdf

http://arxiv.org/abs/0903.3819 Dy photon gammas spectrum

http://www.ippe.obninsk.ru/podr/cjd/kobra13.php?SubentID=30974002

http://www.americanelements.com/thoxst.html

http://arxiv.org/pdf/physics/0404119

NIM_A535_2004_93[1]

File:NIM A590 2008 pg134 Eberhardt.pdf Prep Targets

Neutron cross sections for different elements Media:Neutron_cross_sections.pdf

http://www-nds.iaea.org/RIPL-2/

Media:n gamma cross sections at 25 keV.jpg

Media:n alpha cross section at 14.2 MeV.jpg

Media:ne cross section at 14 MeV.jpg

Media:high enegy fission x-section.jpg

Media:N_gamma_x-section_at_400_keV.jpg

Media:x-sections of reactions at 14 MeV.jpg

Media:n p x-section at 14.3MeV.jpg

Media: n gamma x-section at 14.5 MeV.jpg

Media: elastic x-section at 0.5 MeV.jpg

Media: n gamma x-section at 1 MeV.jpg

Media: n 2n x-section at 14.3 MeV.jpg

Donald James Hughes, Neutron cross sections, 2nd edition 1958, u.s.a atomic energy commission.Media:Neutron cross sections.pdf

File:NSAE 151 2005 319-334 Y.D. Lee.pdf

TGEM-2009 File:TGEM 2009.pdf

12 Volt power supply system.

http://www.lnf.infn.it/esperimenti/imagem/doc/NIMA_46128.pdf

http://electrontube.com.Media: rp097mono HV divier.pdf

http://www.cerac.com/pubs/proddata/thf4.htm#anchor550078

http://en.wikipedia.org/wiki/PC_board

GEANT4_Paticles_Models[2]

Resistors online store : http://www.justradios.com/rescart.html

RETGEMs

Media:Jinst8_02_p02012_THGEM_spark.pdf

- Thick GEM COBRA

Media: Nucl_Phys_B_Bidault_ novel UV photon detector.pdf

Media:Mauro micro pattern gaseuos detectors.pdf

Media:Development and First Tests of GEM-Like Detectors With Resistive Electrodes.pdf

http://www.supplydivision.co.uk/genitem.htm

Thick_GEM_versus_thin_GEM_in_two_phase_argon_avalanche_detectors (HV circuit)[3]

Stainless Steel deflection [4]

Th-Xsection references

File:Th-232 fxsection Behrens 0.7-1.4MeV.pdf

File:Th-232 fxsection Blons 1975 1.2-1.8MeV.pdf

File:Th-232 fxsection ermagambetov 0-3MeV.pdf

File:Th-232 fxsection Henkel 0-9MeV.pdf

File:Th-232 fxsection Ohsawa original.pdf

File:Th-232 fxsection pankratov 3-35MeV.pdf

File:Th-232 fxsection protopopov distancefromthesource.pdf

File:Th-232 fxsection rago 12.5-18MeV.pdf

U-238-Xsection and coating references

relative cross section and calibration samples characteristics for a well determined number of fissions per second

File:Eismont relative absolute nf induced intermediate energy.pdf

- U_238 cross section error analysis

INTERNATIONAL EVALUATION OF NEUTRON CROSS-SECTION STANDARDS, INTERNATIONAL ATOMIC ENERGY AGENCY,VIENNA, 2007 File:U238-xsection.pdf

U_238 (0.5-4MeV) and Th_232 (1-6MeV) fission cross section with statistical error.File:Th-232 U238 xsetion data ebars.txt

File:Pankratov fxsection Th232 U233 U235 Np237 U238 5-37MeV.pdf

Thorium Coating

ThF4 target for sputtering coatings

http://www.cerac.com/pubs/proddata/thf4.htm

Machining Uranium

Uranium will ignite in powder form

http://www.springerlink.com/content/rr072r52163x0833/

- coating Uranium

http://cat.inist.fr/?aModele=afficheN&cpsidt=16864172

Calorimeters/Detectors: DU sheet is in wide-scale use as an absorber material in high-energy physics research at large accelerator laboratories. The high atomic number and density of DU presents a large number of atoms per unit volume to interact with the particles emerging from collisions in these detectors. Also the slight background radiation from DU enables in situ calibration of the electronic read out devices within such detectors, thereby improving the accuracy of measurement.

http://www.2spi.com/catalog/chem/depleted-uranium-products.html

- IAEA Photonuclear Data Library [5]

- Data Acquisition

Warren_logbook[6]

Warren_Thesis [7]

Related To Gaseous Detectors

Breakdown and Detector Failure (10/21/10)

- Different kind of micro-pattern detectors

- References

1- A. Bressan, M. Hocha : NIM A 424 (1999) 321—342 File:High rate behavior and discharge limits in micro-pattern detectors .pdf

2- Fonte and Peskov IEEE 1999 :File:Fundamental limitations of high rate gaseous detectors.pdf

3- B. Schmidt: NIM A 419 (1998) 230—238 File:Microstrip gas chambers Recent developments radiation damage.pdf

Ideas

1.) Can we mix resistive paste (Encre MINICO) with TH-232. We construct a "bed of nails" to place a predrilled G-10 board with a copper border. The nails fill in the holes of the G-10 to keep the paste out. Ecre MINICO is a resistive paste used for transistors.

a.) Get some resistive paste.

http://www.leggesystems.com/p-253-elimstat-uxm-ccp.aspx

Resistive glue to compare

http://www.ellsworth.com/conformal.html?tab=Products

http://www.ellsworth.com/display/productdetail.html?productid=764&Tab=Products

http://www.ellsworth.com/display/productdetail.html?productid=2067&Tab=Products

http://www.cotronics.com/vo/cotr/ea_electricalresistant.htm

b.) mix with a metal similar to Th-232.

c.) construct bed of 0.4 mm nails. Look for 0.4 mm diameter pins.

7/31/2009

New vendor for carbon paste.

http://www.electrapolymers.com/productItem.asp?id=33

The data sheet does not show any information about the thickness of the paste.

The company has a distributor in the usa (877)-867-9668. A phone call is expected on Sat. 8/3/2009 about the availability of the product.

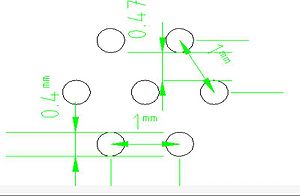

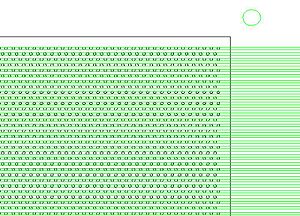

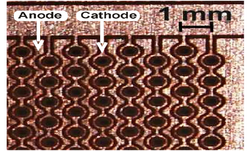

TGEM Mask Design

Coating U-238 or Th-232 is essential for neutron detection in the range 2-14 MeV, but THGEM contains holes that should be protected from any coating material. So, a mask is designed to cover these holes. The holes are in drilled to be on the corners of hexagonal of 1mm side length as in the figure:

The mask is made of stainless steel, 10 um laser tolerance with cut the plate to get the shape in the figure:

Please look at the following files for more details:

Make number bold black font. Add color so it is clear that they are holes in a material.

P_D

Vendor

Thick Film Screen Printers

http://www.sciquip.com/browses/browse_Cat.asp?Category=Screen+Printers