Difference between revisions of "CLAS12 R1 Progress Reports"

m (→10/14/11) |

m (→10/14/11) |

||

| Line 151: | Line 151: | ||

[[file:10142011_Temp1.png | 400 px]] [[file:10142011_Temp2.png | 400 px]] | [[file:10142011_Temp1.png | 400 px]] [[file:10142011_Temp2.png | 400 px]] | ||

| − | While working as the bottom stringer, I noticed my cleanroom cap making contact with the crimp pins near the nose. This prompted me to find a way to prevent any contact with the crimp pins. My solution was to cut out a piece of my black foam board and attaching it to the rails of the endplate. The crimp pins did not appear to protrude past the endplate rails and the double sided tape used to keep the board attached to the rails are about 2mm thick, so there shouldn't be any contact with the board and the crimp pins. I also verified this visually. | + | While working as the bottom stringer, I noticed my cleanroom cap making contact with the crimp pins near the nose. This prompted me to find a way to prevent any further contact with the crimp pins. My solution was to cut out a piece of my black foam board and attaching it to the rails of the endplate. The crimp pins did not appear to protrude past the endplate rails and the double sided tape used to keep the board attached to the rails are about 2mm thick, so there shouldn't be any contact with the board and the crimp pins. I also verified this visually. |

[[file:10142011_Board.jpg | 400 px]] | [[file:10142011_Board.jpg | 400 px]] | ||

Revision as of 20:46, 16 October 2011

The Drift Chamber Wiki at JLab

Clean room Prep

Clean room Construction 2011

Jlab Shipment 8/8/2011

Jlab Stringing Prep

Install fixtures

8/9/11

Installed the crane

Brought down the platforms

Bring down the scissor lifts

8/17/11

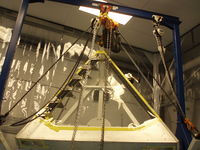

Install A-Frame for mounting DCs

Mounting Sector 1 DC

Changing Room

8/23/11

Finished installing the changing room. The changing room is used to put on clean room apparel prior to entering the clean room. A HEPA filter is placed on top of the room and set to high in order to blow particles off a person before they enter the clean room.

We still need to install a hard door between the changing room and the clean room.

Clean Room 8/23/11

September 2011

October 2011

10/7/11

63 wires were strung today.

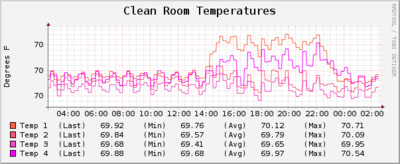

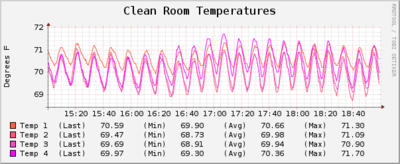

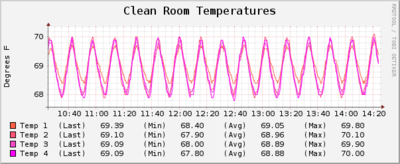

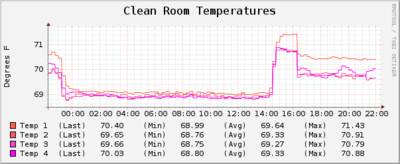

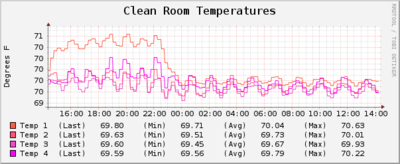

14:00 on the temperature graph is 8:00 AM.

10/10/11

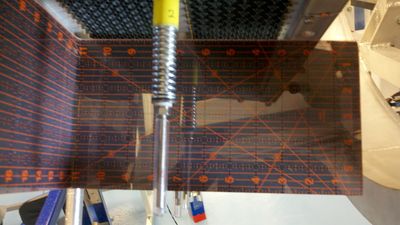

In an effort to increase the speed and accuracy of the tensioner, I (Larry) made this little do-hicky:

This is a Fiskars 6"x24" Acrylic Ruler with black foam board glued to the backside. I used a heat gun to bend it 90°. I was just trying this out to see how well it works. If my stringers like it, I will remove the foam board and paint the backside black.

The lines on the acrylic ruler allow a stringer to more easily position the wire perpendicular to the end plate when adjusting the pulley used for hanging weights.

The glossy finish might pose a problem, but we will give it a try and see how it works out.

Temperatures this afternoon climbed up to 71.7°. This does not show up on the 5 minute average, so here is the 1 minute average.

Temperature sensitivity (%Delta;t) was changed to ±1° at around 12:45 PM. Will continue to monitor this.

Changing the sensitivity caused our average to drop about 0.5° but the amplitude of our fluctuations decreased. The minimum is lower than I would like, so the sensitivity is being changed back to ±2° at 3:20 PM.

The HVAC filters showed up this afternoon, so this is being replaced. I will continue to monitor temperatures tomorrow. If temperatures climb back up to 72° again, I will change our sensitivity back down to ±1° as well as change our temperature setpoint to 69° (up 1°) in an attempt to keep our average closer to 70°.

63 field wires were strung today.

10/11/11

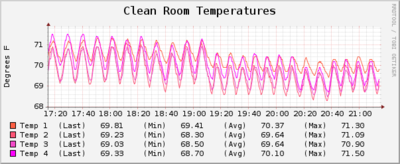

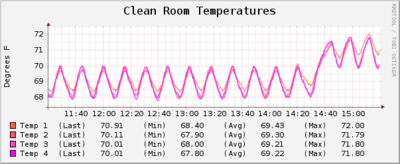

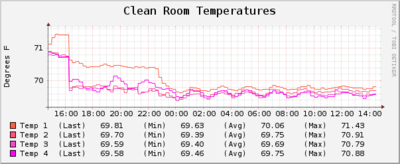

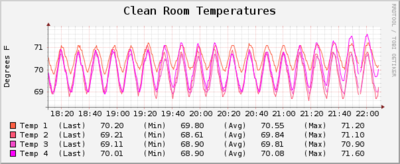

It appears that changing our HVAC filter dropped our average temperature to 69° with fluctuations of ±1°.

The temperature setpoint is being increased to 69° in an attempt to get our average to 70°. This was done around 9 AM.

This change did not work as hoped for. This 1° change in our setpoint increased our cleanroom average temperature to 71° with fluctuations of ±1°.

There was no stringing done this morning.

The temperature set point was changed back to 68°. The average temperature did not drop back down to 69°, but only dropped down to 70°.

Stringing resumed once temperatures stayed within acceptable levels (~11 AM).

Average temperatures remained right at 70° with ±1° fluctuations the remainder of the day, even with both of us stringing and measuring tensions.

Even with no stringing this morning, Marcie and I still managed to string 63 wires today.

10/12/11

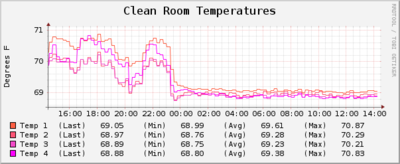

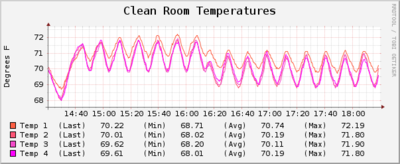

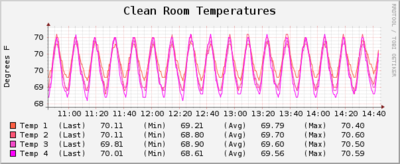

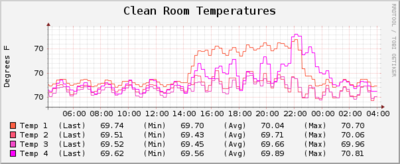

Temperatures look much better this morning. Screenshots were taken at 8:45 AM.

It was just me (Larry) stringing today, but I still managed to string 42 wires.

My do-hicky seems to be working out well (see pics at 10/10/11). It seems to speed up tensioning wires. Marcie likes it as well.

10/13/11

63 wires were strung today.

10/14/11

98 wires were strung today.

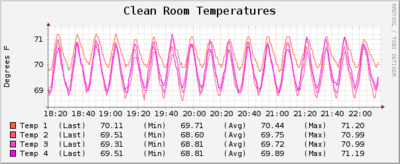

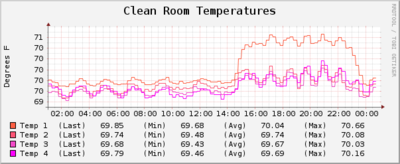

After measuring tension for an extended period of time, temperatures started to climb past 71°. They still remained under 72°.

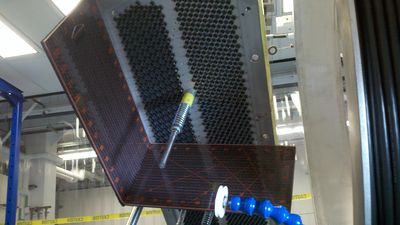

While working as the bottom stringer, I noticed my cleanroom cap making contact with the crimp pins near the nose. This prompted me to find a way to prevent any further contact with the crimp pins. My solution was to cut out a piece of my black foam board and attaching it to the rails of the endplate. The crimp pins did not appear to protrude past the endplate rails and the double sided tape used to keep the board attached to the rails are about 2mm thick, so there shouldn't be any contact with the board and the crimp pins. I also verified this visually.

This was just a simple and quick way to solve this problem. A more permanent solution will be made once I am afforded the time. Maybe a thin sheet of aluminum with 1/8" spacers.