Difference between revisions of "CLAS12 R1 Progress Reports"

m (→10/11/2011) |

m (→10/11/11) |

||

| Line 218: | Line 218: | ||

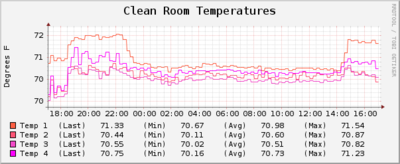

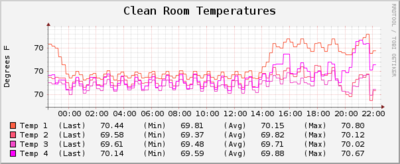

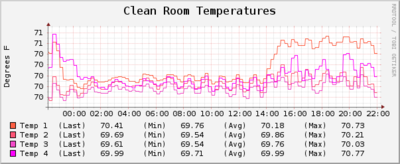

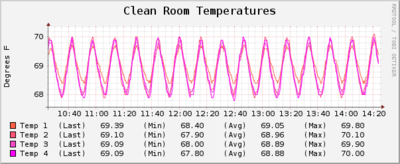

It appears that changing our HVAC filter dropped our average temperature to 69° with fluctuations of ±1°. | It appears that changing our HVAC filter dropped our average temperature to 69° with fluctuations of ±1°. | ||

| − | [[file:10112011_CleanroomTemperature_1.png | 400 px]] | + | [[file:10112011_CleanroomTemperature_1.png | 400 px]] [[file:10112011_CleanroomTemperature_2.png | 400 px]] |

The temperature setpoint is being increased to 69° in an attempt to get our average to 70°. | The temperature setpoint is being increased to 69° in an attempt to get our average to 70°. | ||

Revision as of 14:27, 11 October 2011

The Drift Chamber Wiki at JLab

Clean room Prep

Clean room Construction 2011

Jlab Shipment 8/8/2011

Jlab Stringing Prep

Install fixtures

8/9/11

Installed the crane

Brought down the platforms

Bring down the scissor lifts

8/17/11

Install A-Frame for mounting DCs

Mounting Sector 1 DC

Changing Room

8/23/11

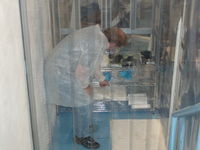

Finished installing the changing room. The changing room is used to put on clean room apparel prior to entering the clean room. A HEPA filter is placed on top of the room and set to high in order to blow particles off a person before they enter the clean room.

We still need to install a hard door between the changing room and the clean room.

Clean Room 8/23/11

September

9/22/11

The doors into the clean room have been sealed by temporary walls for the renovation project which will start in the room next door. Below is a picture of the wall which has sheet rock on top of a plastic cover surrounding metal studs. The wall has been calked on the outside to prevent dust from coming through.

Also note that the HVAC temperature setpoint was changed to 68° F around noon.

9/23/11

2 - 480 V outlets have been installed.

Cleanroom fans were turned on this afternoon around 2:30 PM.

9/25/11

The chamber was wiped down and vacuumed.

All of the pre-tensioners have been set to a spring height of 1.75".

9/26/11 - Stringing Begins

Temperature fluctuations were within ± 2° during the stringing

HVAC temperature setting was dropped to 67° from 68° and the Δt was changed from ±2° to ±4° at around 1 PM.

Due to the late start this afternoon, we were only able to string 3 guard wires.

9/27/11

Temperature fluctuations were within ± 1° during the stringing

With 3 stringers rotating, we were able to string 45 Guard wires today.

9/28/11

A strip door was installed between the cleanroom area and the beam lab counting room. Several ducting pipes that are connected to adjacent rooms were also sealed off.

69 Guard wires were strung today.

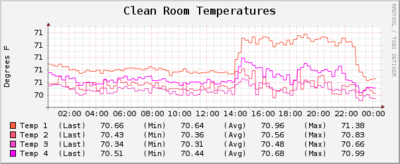

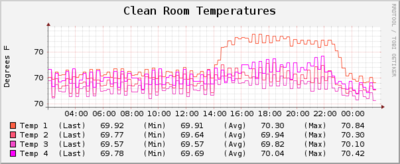

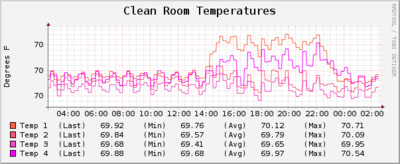

The graph below was drawn at 6:32 pm on 9/29/11. It seems time stamp 0:00 corresponds to 6pm. It appears that the stringers enter the clean room around 8am (14:00) and warm up the clean room by almost 1 degree. TEMP4 is a thermometer on the vinyl wall right next to the chamber that is currently being strung. Temp1 is the middle of the clean room. Temp2 and Temp3 are on the opposite wall to the drift chamber currently being strung.

9/29/11

Since the previous change of our Δt to ±4° only changed the amplitude of our temperature change and didn't change our frequency, our Δt was changed back to ±2° at 2:30 PM.

91 guard wires were strung today.

The HVAC temperature set point was increased to 68° F at 4:15 PM.

9/30/11

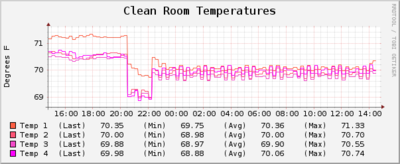

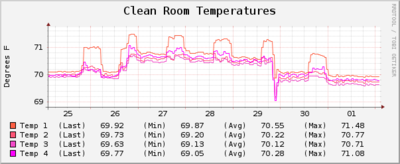

The HVAC temperature set point was increased to 68° F yesterday at 4:15 PM.

The overnight temperatures are shown below (image taken at 8:45 am on 9/30/11)

Guard wires for SL2 were completed at 11:30 AM.

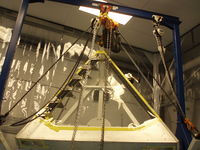

Pictures below show us rotating the chamber in preparation for stinging SL1 guard wires.

We started stringing guard wires for SL1. Total wires strung today: 51.

- Average Temperature for the First week of stringing

October

10/3/11

124 guard wires were strung today.

10/4/11

90 guard wires were strung today.

All guard wires have been strung.

The chamber has been rotated and we will start stringing field wires tomorrow.

10/5/11

48 field wires were strung today. Tension measurements were made for all of these wires also.

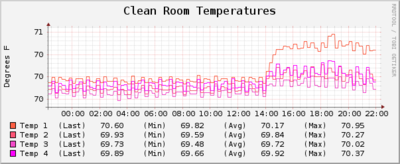

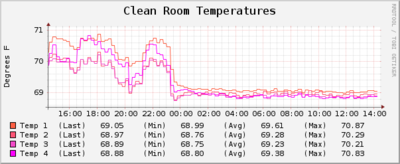

Temperature measurements are odd and are a concern. Will continue to monitor this. Possibly the heat created by the magnet and it's proximity to the temperature sensor?

10/6/11

49 field wires were strung today as well as 8 redo's.

10/7/11

63 wires were strung today.

14:00 on the temperature graph is 8:00 AM.

10/10/11

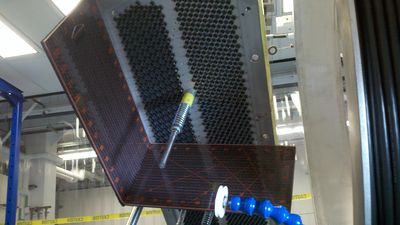

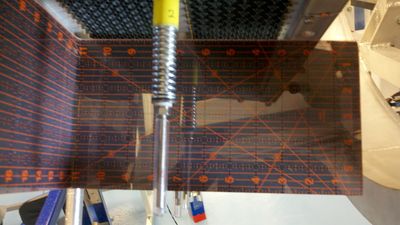

In an effort to increase the speed and accuracy of the tensioner, I (Larry) made this little do-hicky:

The lines on the acrylic allow a stringer to more easily position the wire perpendicular to the endplate when adjusting the pulley used for hanging weights.

The glossy finish might pose a problem, but we will give it a try and see how it works out.

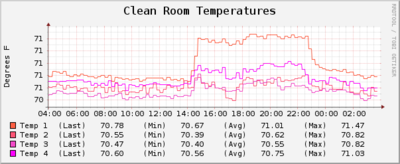

Temperatures this afternoon climbed up to 71.7°. This does not show up on the 5 minute average, so here is the 1 minute average.

Temperature sensitivity (%Delta;t) was changed to ±1° at around 12:45 PM. Will continue to monitor this.

Changing the sensitivity caused our average to drop about 0.5° but the amplitude of our fluctuations decreased. The minimum is lower than I would like, so the sensitivity is being changed back to ±2° at 3:20 PM.

The HVAC filters showed up this afternoon, so this is being replaced. I will continue to monitor temperatures tomorrow. If temperatures climb back up to 72° again, I will change our sensitivity back down to ±1° as well as change our temperature setpoint to 69° (up 1°) in an attempt to keep our average closer to 70°.

63 field wires were strung today.

10/11/11

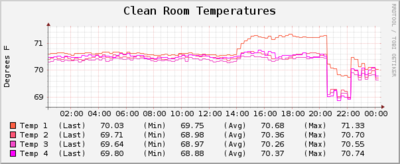

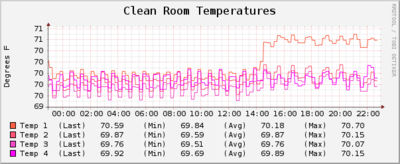

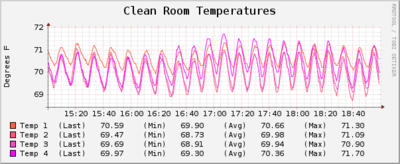

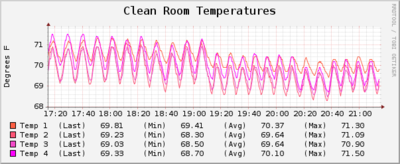

It appears that changing our HVAC filter dropped our average temperature to 69° with fluctuations of ±1°.

The temperature setpoint is being increased to 69° in an attempt to get our average to 70°.