CLAS12 R1

Time line

Time needed to train lead stringer at JLab = 4-6 weeks?

| Start Date | End Date | Actually End Date | Description |

| 5/17/10 | 9/30/10 | 8/6/10 | Sign MOU |

| 5/17/10 | 9/30/11 | 4/12/11 | Contract recieved |

| 8/3/2010 | 8/3/2010 | Readiness Review | |

| 9/1/10 | 10/29/10 | Hire and train R1 Lead Stringer | |

| 10/1/10 | 2/28/11 | Hire and train 2 R1 stringers | |

| 11/16/09 | 11/30/10 | Build R1 Cleanroom | |

| 11/5/2010 | 11/12/2011 | Ship 1st R1 Box From JLab to ISU | |

| 12/17/2010 | 2/28/2011 | String First R1 Chambers | |

| 2/21/2011 | 3/31/2011 | Ship remaining R1 Boxes From JLab to ISU | |

| 7/13/12 | Complete 6th R1 chamber | ||

| 4/5/13 | 9/30/13 | Ship chambers, fixtures, platforms and crane to JLab |

| Week | Expected Date | Actual Date | Description |

| 0 | April 4, 2011 | 4/12/11 | Issue Construction contract |

| 4 | May 2,2011 | 6/13/11 | Hire lead stringer send to JLab for training |

| 14 | July 11, 2011 | August 18, 2011 | Clean room installed at ISU, Readiness Review, Hire 1st stringing team |

| Nov, 2011 | Finish guard and field wires on Region 1 Chamber 2 | ||

| 36 | Dec. 12, 2011 | Hire and begin training 2nd stringing team | |

| 40 | Jan. 9, 2012 | Begin stringing R1 Chamber 3 | |

| 45 | Feb. 13, 2012 | Complete stringing R1 C2 | |

| 66 | July 9, 2012 | Complete Stringing R1 C3 | |

| 71 | Aug. 13, 2012 | Complete Stringing R1 C4 | |

| 94 | Jan. 21, 2013 | Complete Stringing R1 C5 | |

| 97 | Feb 11, 2013 | Complete Stringing R1 C6 | |

| 104 | April 1, 2013 | Ship chambers, fixtures, platforms and crane to JLab |

4 ingredients to contract

1.) MOU: Memorandum of Understanding,

2.) SOW: Statement of Work

3.) Detailed Schedule

4.) Sole Source Justification

5.) Contact person: Pre Award Dave Harris? Approve Terms and conditions

University gets a Purchase Req: covers SOW, Terms & Condition, & Schedule.

We respond with proposal containing exceptions and work plan. 1 team of 2 stringers can do a wire in 6 minutes. Stringers spend 1/2 of their time stringing the rest of time preparing , Q&A, ... JLab expects a crew of 5 people. If we think we can't make the schedule we need to ask for more people. Stringers hourly rate ($30-$35/hr with overhead and benefits). Lead stringer is +$5/hr more.

Then they respond with contract.

"Cost Reimbursable" contract, University not liable if we go over budget

Can we survey to 50 microns? No. 200 microns.

| Items From JLab |

| $2,500 Crane to mount DC (use grant to buy) |

| (Done) comes with stringing fixtures!. platform to take chamber from upper level to lower |

| JLab will order 2 Man Lifts to reach 15' |

| Primary magnets for wire tension measurements will be sent by JLab (We have budgeted for power supply get one that is 15 V, 100 amp Analog better than switching) |

Purchasing

Things we need to buy and when they need to be here

Equipment

| Arrival Date | Item to Purchase | Sample Item | Lead Time | Budget | Cost | Done |

| 6/10/11 | Get Shipping Company for Clean room (??? Weight and Dimensions) | quote from CleanAirQuote from shipper | 1925 | yes | ||

| 6/13/11 | Get Mobile Crane Company for Clean room Unloading | 1-2 days | ? | yes | ||

| 6/20/11 | $2,500 Crane to mount DC (use grant to buy) | Arnold Machinery | 7-10 days | 2882 | yes | |

| 6/20/11 | Crane chain and chain hoists (use grant to buy) | Empire Machinery | 7-10 days | 1155 | yes | |

| 8/1/11 | Clean room Quality worktable ( ?? Quantity & Size) | Stainless Steel Top Item 1521-55 | 1530 | 1198 | Yes | |

| 8/1/11 | 2 Clean room Quality Storage Cabinet | Acrylic Storage Cabinets 9011-07 | 2800 | 911x2 | Yes | |

| 8/1/11 | 2 Clean room Quality Utility carts | Utility Carts 1401-46 | 1200 | 599x2 | Yes | |

| 8/1/11 | 4 Clean room Quality chairs | Ergonomic Lab Chairs 2801-02 | 1 week | 1000 | 366x4 | yes |

| 8/1/11 | 1 Clean room Quality tool chest | 1000 | ||||

| 8/1/11 | 1 Clean room Quality and fire safe trash containers and bags | Stainless Steel 24Gallon 1456-03 | 1 week | 1000 | 550 | Yes (need more bags) |

| 8/1/11 | Primary magnets power suppllies 15 V, 100 amp Analog better than switching | 3000 | ||||

| 8/1/11 | Clean room Particle Counter | Kanomax 3887 Handheld Laser Particle Counter. 0.3 - 5.0 microns, 3 Channels, 0.1 CFM. | 3 days | 2000 | 1875 | yes |

| 8/1/11 | CAEN N479 or equivalent | 6000 |

Consumables

| Need to Order? | Item to Purchase | Budget | Cost | Vendor |

| No | Frocks and pants | 3000 | ||

| No | Shoe cover | 1000 | http://www.pro-tect.com/Pro-Tect-Catalog/Jobsite/Shoe-Booties.html or 4953-59 and 4953-60 | |

| No | head covers | 1000 | 4953-85 | |

| Headcover + mask in one | 1000 | Clas 100 rating so overkill 4953-15 | ||

| - | Face masks | 800 | ||

| No | nitrile gloves (L, M) | 27000 | http://www.terrauniversal.com/cleanroom-equipment/qualatrile-nitrile-gloves.php | |

| No | Lint free clean room wipes | 4000 | http://www.terrauniversal.com/cleanroom-equipment/cleanroom-wipers.php#nonwoven | |

| Yes | tacky mats | 1800 | http://www.pro-tect.com/Pro-Tect-Catalog/Surface-Protection/Tacky-Mats.html | |

| Yes | 18" tacky roller with replacement heads (3" core) | 500 | http://www.cleanroomworld.com/category/index.cfm?cid=153&lvl=3 (no 3" replacement heads?) | |

| Yes | glue applicator syringe | 400 | http://www.hobbylinc.com/htm/hca/hcahcar3785.htm | |

| Yes | Epon 829 Resin (3 year shelf life) | 1300 | ||

| Yes | Versamid 140 Hardener (?? shelf life) | 800 | ||

| Yes | Staticide - anti-static cleaner | ? | http://www.aclstaticide.com/01/index.html |

ISU Clean Room Facility

- The chamber's longest wire should be lifted 4 ft off the floor.

- Need a hand rail system so people don't fall off the ledge because they mistake the clean room wall for a solid structure.

File:BasementRenovationDrawing 6-16-10.pdf

File:BasementRenovationDrawing 6-28-10.pdf Changes to machine shop door

File:BasementRenovationDrawing 7-26-10.pdf Maybe the Final design with 8' hallways and 8' doors to the clean room

Media:Series575_CleanRoom_InstallManual.pdf

Ed cash : 242-8192 (manages electricians, call to be sure work order is in place for )

CLAS 10,000

Definition

| Class | maximum particles/m³ | FED STD 209E equivalent | |||||

|---|---|---|---|---|---|---|---|

| ≥0.1 µm | ≥0.2 µm | ≥0.3 µm | ≥0.5 µm | ≥1 µm | ≥5 µm | ||

| ISO 7 | 352,000 | 83,200 | 2,930 | Class 10,000 | |||

| ISO 9 | 35,200,000 | 8,320,000 | 293,000 | Room air | |||

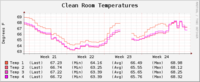

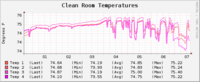

ISU Clean room Environment monitors

Temperature

Temp1 == Top of clean room middle.

Temp2 == South wall bottom

Temp3 == South wall top

http://hal.iac.isu.edu/cacti-graphs/graph_6.html

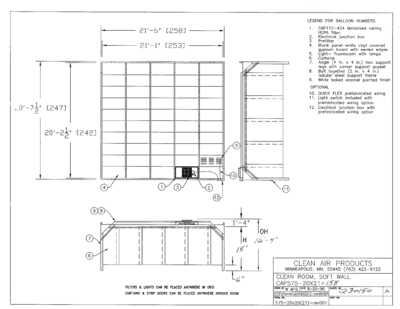

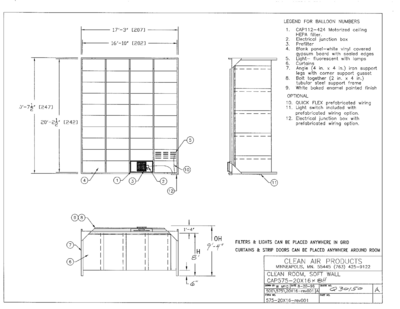

The ISU clean rooom is 20' x 21' x 15' = 6300 ft^3 = 178 m^3

PhysicsCleanRoomParticleCountLog

Clean_Room_Particle_Counter_User_Directions

Construction Quotes

We are currently waiting on quotes from the following companies on the construction of the Clean Room (both specs) at ISU. They are Modular Clean Rooms and Clean Air Products. Once quotes are received, pdf's of the quotes will be uploaded online.

2010 July 14

Quote from Clean Air Products for the ISU Basement:

Latest quote

File:Clean Air Quote 4-27-11.pdf

File:Clean Air Quote 10-15-10.pdfFile:Clean Air FilterQuote 10-15-10.pdf

File:Clean Air FilterDescript 10-15-10.pdf

File:Clean Air Quote No Filters.pdf

Dimensions of door from loading dock to clean room 65" wide 90" high

The doors into and out of the different areas will be 9'8" high in order to help facilitate the transport of equipment into and out of the different areas of the clean room.

The desks in the clean room will act as a table top area to place tools and other equipment currently in use during the construction of the wire chambers. Also, they will serve as a place to perform any calculations or other miscellaneous work that may come up while construction is ongoing.

The cabinets on the other side of the room will be a permanent storage area for all tools and equipment not currently in use at the two work stations.

The path in between the workstations and the cabinets will be kept clear of all obstructions in order facilitate the movement of equipment into and out of the room as needed.

The two workstations will be where the wire chambers are constructed. The workstations will have a standing/sitting apparatus built around them in order to help those who are stringing the wire chambers to have better access to the chambers from above. Schematics for these will be uploaded as they are designed.

The heavy equipment storage area will be where all the heavier equipment (i.e. dollies, fabrication materials, etc...) that will not fit, or does not need to be stored in the individual work station cabinets will be kept.

The HEPA filters will cover roughly ~10-12% of the ceiling in order to maintain a Class 10,000 environment. The filters will move approximately 35-40 air volumes per hour.

Overhead lighting will be suspended from the frame in order to provide sufficient lighting for the room occupants to work within.

Floor paint

File:ArmoSeal1000epoxypaint.pdf

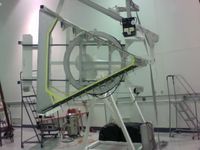

Pictures of Path from Dock to clean room

As measured on the spit in the JLab clean room on April 28, 2011. The narrowest part of the R1 detector was 78". A door should accomodate 78" + box.

The Tip of the stringing fixture was 13' 5" high from the floor.

Below are pictures showing how our R1 mock up, an equilateral triangle 8' on the side, passes from the loading dock to the clean room area.

|

|

| The 8' wide mock up is a few inches larger than the loading dock door. | The mock up is just able to pass through the door when standing up. |

The R1 chambers will pass through 2 newly cut doorways to the clean room

|

|

| The 8' wide mock has several inches to spare going through the first doorway. | The second doorway is the same width as the first. |

- Photos courtesy of Dr. Philip Cole

Pictures of the ISU Squash Court

6/18/09

The clean room needs space for instrumenting. The DC will be layed horizontal so PC cards can be mounted and tested.

6/24/10

11' = hook height in stringing clean room

There are 2 stringing strong back and 6 shipping strong backs. They bolt on separate sides of the chambers.

Idea: Instrument the chamber on the ledge above the squash court. Put a lift on the pole which we can use to turn the DC from its standing (stringing) position to its horizontal (instrumentation) position then "swing" it over onto the squash court ledge.

No Halogen lighting.

Think about air conditioning. People are space heaters.

Have shoes specific for clean room instead of booties.

Clean room floor plan for Basement and Airport

Here is a preliminary floor plan for the Updated clean room in the ISU Basement

File:Clean Room Squash Court.eps

replace the above with a PNG or JPG file so we can see it in the wiki

Pros and Cons of Locations

- Physics Basement

- Pros

1.) similar size to ODU just 5 feet shorter.

20x39x15' -vs- 20x40x20;

2.) more quality control: 4 Physics professors more likely to look in on construction in between classes

3.)established record of temperature control

4.) closer to other facilities; machine shops, electronics, ...

- Cons

1.) must move detector standing up to get through 6' hallway

2.) more heavy lifting when bringing in and out of basement (this is only 2 day out of the months involved in construction)

- Airport

- Pros

1.) Plenty of Room

- Cons

1.)adds > $10k to cost of clean room

2.) far away from professors eyes (could be a pro)

ODU's Clean Room

ODU's current clean room size:

20 ' high 20 ' Width 40 ' Length

CLAS 10,00 clean rooms

Environmental control needed

Temperature control constraint is

The wire tension can fluctuate no more than 5% from the mean wire tension specification.

This means that the temperature should be controlled to within +/- 2 Degrees Ferenheit

Humidity control: 55 % or less

File:KashyHallBTempReport 2-09.docFile:KashyHallBTempReport 2-09.pdf

Online Room Temp monitors

http://hal.iac.isu.edu/cacti-graphs/graph_6.html

HVAC performance June 2011

The HVAC system has been repaired. It was set to a temperature of 66 +/- 2 degree F. I saw the cooling light turn on at least once. On June 21,2011 the set point was changed from 66 to 72.

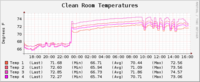

Below is a snapshot after I turned the set point from 66 to 72. It looks like the cycle time was about 20 minutes when set to 66 degrees and 2 degree stability.

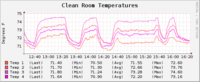

The temperatures measured after changing the temperature set point to 72.

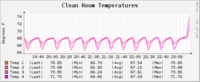

Temperature Oscillations observed before adding a tarp over the large doorway

Some IAC personnel moved the tarp for a little while at time index 18:40. Fortunately there will be 2 doors put in. One where the tarp is now and another 5 feet towards the basement exit. Otherwise, I would worry about the impact of opening the large door on stringing.

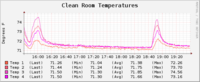

The temperature seems to be more stable now with the tarp over the doorway, allowing the HVAC to control the temperature in only the clean room area. Below is a graph of the temperature in the room over a 6 hour period starting at 8 am until 2 pm on June 24, 2011.

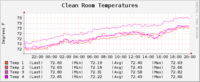

Below is a plot of the temperatures recorded over the last 7 days (4/18 - 24 / 11) when all the changes were happening to try and bring the temperature up to 72 degrees.

Below is a plot of the temperatures recorded over the last 7 days (4/21 - 27 / 11) . There appears to be a slow rise?

- 6/28/11

I went down to the clean room and and saw that the Duct work was started. There are open holes into the adjacent room right now which need to be closed up.

- I also saw that the set point has been raise to 73 degrees. This explains the temperature rise above.

- 8/11/11

Began moving the temperature sensors to new locations in the clean room. We plan on mounting them at locations which will measure the stringing temperature at the top and bottom of a chamber while we are stringing the chamber

- 8/24/11

Installed an air deflector on the vent furthest from the HVAC unit at approximately 11:30 AM.

July 2011 HVAC performance

6/6/11

Construction begins in the clean room. I opened the tarp over our big door a little bit and now I see temperature oscillations again.

6/7/11

The first few days of July were stable but there was a positive temperature gradient slowly increasing the temperature about +1/3 degree F per day. Then on July 4 something caused temperatures to fluctuate at least 1 degree within a day. Could it be that the university turned off the AC over the weekend and there was a delay seeing the building aclimate?

Cleaning Procedures

R1 Construction preparations

Wire Tension

A Helmholtz coil is used to test the wire tension

Below is a write up from BaBar

File:Device2MeasureWireTension Covery BaBarReportTNDC-96-39 1996.pdf

File:ODU WireTensionMeasurements 10-2009.pdf

An excel spreadsheet to calculate fields for such coils is given at

http://clasweb.jlab.org/drawings/CLAS12/DRIFT_CHAMBERS/Helmholz_calculator.xls

The formula is from Physics 10X but more importantly it contains wire parameters useful for the calculation

Discussion items

1.) Budget

- JLab to ISU travel for JLab personnel to inspect operations

- shipping container for R1 chambers

2.) Clean room

cost =

assume we copy the ODU clean room

Using IAC conference room space, need to remove carpet and paint floor.

3.) hiring timeline

9/08 NSF proposal submission

4.) stringing platform and DC stringing support arm

5.) Manpower

6.) MOU to support post doc request or faculty release time

7.) Stringing equipment

a.) crimping tool

b.) glue

c.) wire or feedthroughs?

d.) wire tension measurement (PC, Magnets, associated electronics

A few pictures ff the R1 full size proto type from my JLab visit on 9/16/07. It is about 6 feet tall. CLAS12_R1_Prototype_9-16-07

The air actuated crimping tool:

Construction First R1 Chamber at JLab

As measured on the spit in the JLab clean room on April 28, 2011. The narrowest part of the R1 detector was 78". A door should accomodate 78" + box.

The Tip of the stringing fixture was 13' 5" high from the floor.

|

|

|

|

|

|

R1 Proceedures

Gas flow operation

Standard operating pressure is 0.05" inches of water.

the bubbler exhaust tip should barely touch the oil enough to cause bubbles.

http://clasweb.jlab.org/drawings/CLAS12/DRIFT_CHAMBERS/R1_Chamber_Assembly_Procedure.doc

http://clasweb.jlab.org/drawings/CLAS12/DRIFT_CHAMBERS/R1_End_Plate_Assembly_Procedure_RevA.doc

CLAS12 R1 SOW

Readiness Review

CLAS12_R1_Progress_Reports

Vendors

http://www.cleanairproducts.com/

References

Stringing Manual

Media:R1_CLAS12_StringingManual_2008.doc Media:R1_CLAS12_StringingManual_2008.pdf

Media:R1_CLAS12_StringingManual_2011_V1.2.pdf

JLab job posting for lead stringer

add should be available at

https://isujobs.net/applicants/jsp/shared/Welcome_css.jsp

CLAS Wire Chamber Technician

Requisition Number 10534 Job Category Technician/Drafter Percentage of Travel No Travel Job Responsibilities (TERM POSITION ENDING TWO YEARS FROM HIRE DATE)

DATE POSTED: FEBRUARY 11, 2010

SALARY RANGE: $45,500 - $61,900 (TD II)

DUTIES: Technician will be responsible for the fabrication of very large and very precise particle detection units called "wire chambers" in support of the CLAS 12 GEV project. These "wire chambers" will be built in a clean room by teams. Incumbent is expected to lead these fabrication teams. Specifically, individual will be responsible for leading a team in building these detectors and maintaining strict quality controls. Will be required to learn all aspects of detector fabrication, stringing and testing. Will fabricate and string the detectors maintaining high precision and quality. Will receive, clean and inspect parts for compliance with technical specifications.

Experience/Education Required MINIMUM QUALIFICATIONS:

Associates Degree plus 3 years of applicable experience or equivalent combination of education and relevant experience. Knowledge of basic electricity and/or electronics required. Knowledge and experience in the proper use of hand and power tools as well as ability to follow written procedures in operating and technical manuals also required. Basic computer skills such as Excel and/or CAD experience is a plus. Ability to work in a team environment. A background in quality control as well as experience supervising and motivating others in a team setting preferred.

Physical Requirements: - Pass all medical requirements for the following qualifications: Rad Worker, ODH, Crane Operator, Forklift Operator, Aerial Platform Operator, etc. - Cannot have a fear of heights or confined spaces. - Must be able to climb stairs, ladders, vertical escape ladders and work in close quarters with others. - Steady hands and eyes for delicate close-up work.

During interview have them try to crimp a wire.

Master rigger, to manipulate the chamber onto the stringing platform.

Master rigger class at JLab on November 2-4, 2010. Overhead training class pre-req. contact kelley

Overhead crane class,