CLAS12 R1 Progress Reports

The Drift Chamber Wiki at JLab

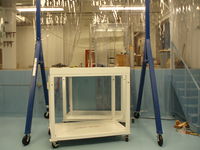

Clean room Prep

Clean room Construction 2011

Jlab Shipment 8/8/2011

Jlab Stringing Prep

Install fixtures

8/9/11

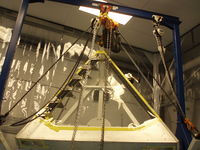

Installed the crane

Brought down the platforms

Bring down the scissor lifts

8/17/11

Install A-Frame for mounting DCs

Mounting Sector 1 DC

Changing Room

8/23/11

Finished installing the changing room. The changing room is used to put on clean room apparel prior to entering the clean room. A HEPA filter is placed on top of the room and set to high in order to blow particles off a person before they enter the clean room.

We still need to install a hard door between the changing room and the clean room.

Clean Room 8/23/11

September 2011

October

10/3/11

124 guard wires were strung today.

10/4/11

90 guard wires were strung today.

All guard wires have been strung.

The chamber has been rotated and we will start stringing field wires tomorrow.

10/5/11

48 field wires were strung today. Tension measurements were made for all of these wires also.

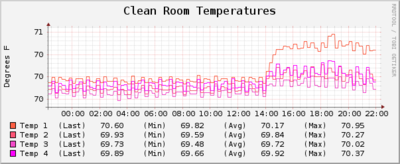

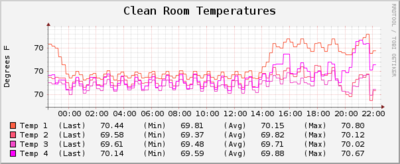

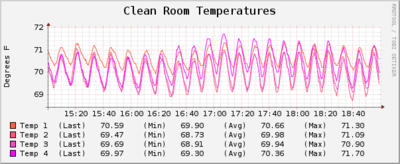

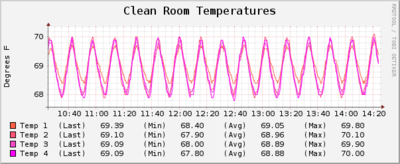

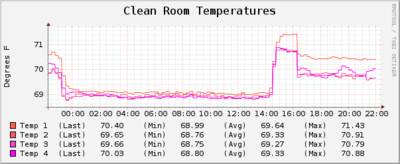

Temperature measurements are odd and are a concern. Will continue to monitor this. Possibly the heat created by the magnet and it's proximity to the temperature sensor?

10/6/11

49 field wires were strung today as well as 8 redo's.

10/7/11

63 wires were strung today.

14:00 on the temperature graph is 8:00 AM.

10/10/11

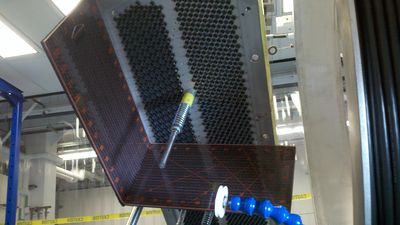

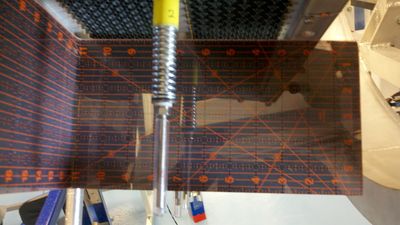

In an effort to increase the speed and accuracy of the tensioner, I (Larry) made this little do-hicky:

This is a Fiskars 6"x24" Acrylic Ruler with black foam board glued to the backside. I used a heat gun to bend it 90°. I was just trying this out to see how well it works. If my stringers like it, I will remove the foam board and paint the backside black.

The lines on the acrylic ruler allow a stringer to more easily position the wire perpendicular to the end plate when adjusting the pulley used for hanging weights.

The glossy finish might pose a problem, but we will give it a try and see how it works out.

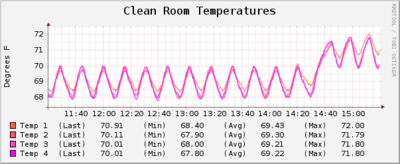

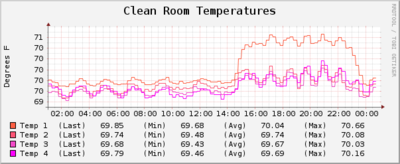

Temperatures this afternoon climbed up to 71.7°. This does not show up on the 5 minute average, so here is the 1 minute average.

Temperature sensitivity (%Delta;t) was changed to ±1° at around 12:45 PM. Will continue to monitor this.

Changing the sensitivity caused our average to drop about 0.5° but the amplitude of our fluctuations decreased. The minimum is lower than I would like, so the sensitivity is being changed back to ±2° at 3:20 PM.

The HVAC filters showed up this afternoon, so this is being replaced. I will continue to monitor temperatures tomorrow. If temperatures climb back up to 72° again, I will change our sensitivity back down to ±1° as well as change our temperature setpoint to 69° (up 1°) in an attempt to keep our average closer to 70°.

63 field wires were strung today.

10/11/11

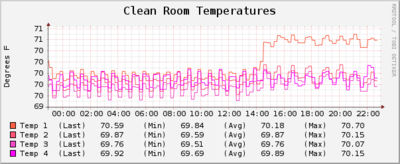

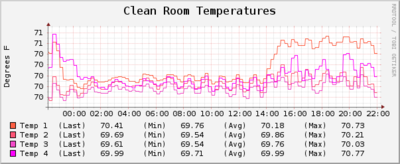

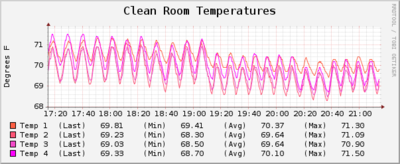

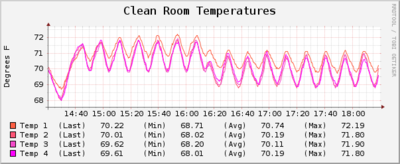

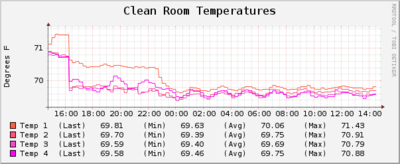

It appears that changing our HVAC filter dropped our average temperature to 69° with fluctuations of ±1°.

The temperature setpoint is being increased to 69° in an attempt to get our average to 70°. This was done around 9 AM.

This change did not work as hoped for. This 1° change in our setpoint increased our cleanroom average temperature to 71° with fluctuations of ±1°.

There was no stringing done this morning.

The temperature set point was changed back to 68°. The average temperature did not drop back down to 69°, but only dropped down to 70°.

Stringing resumed once temperatures stayed within acceptable levels (~11 AM).

Average temperatures remained right at 70° with ±1° fluctuations the remainder of the day, even with both of us stringing and measuring tensions.

Even with no stringing this morning, Marcie and I still managed to string 63 wires today.

10/12/11

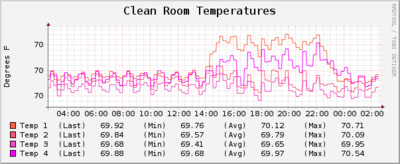

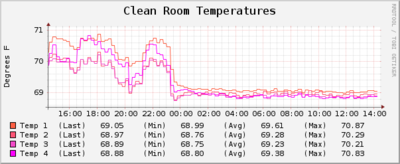

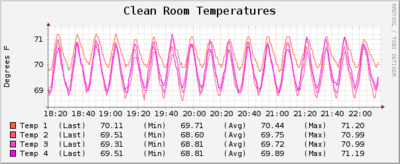

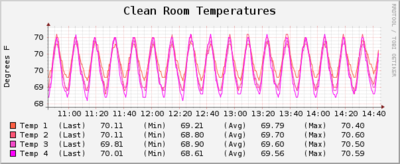

Temperatures look much better this morning. Screenshots were taken at 8:45 AM.

It was just me (Larry) stringing today, but I still managed to string 42 wires.

My do-hicky seems to be working out well (see pics at 10/10/11). It seems to speed up tensioning wires. Marcie likes it as well.