Difference between revisions of "Neutron TGEM Detector Abdel"

| Line 116: | Line 116: | ||

Neutron cross sections for different elements [[Media:Neutron_cross_sections.pdf]] | Neutron cross sections for different elements [[Media:Neutron_cross_sections.pdf]] | ||

| − | |||

http://www-nds.iaea.org/RIPL-2/ | http://www-nds.iaea.org/RIPL-2/ | ||

Revision as of 15:34, 27 February 2009

Haithem's logbook for developing neutron sensitive TGEM detector

1/23/09

image

1.) Search the web for patent which coats GEM detector with neutron sensitive materials. I think it is for Thermal neutrons.

Materials of high neutron capture cross section are studied widely, an example is the following patent

[[1]]

Most of the high neutron capture cross section materials were measured for different neutron energies. A comprehensive work is published in 2000. The project was supported by Korea Atomic Energy Research Institute and Brookhaven National Laboratory [[2]]

U-235 is the one of the best choices since it has a high neutron fission cross section and a long half life compared to other the other isotopes that may come under choice.

A second choice is Th-238 and U-238 which have fission cross section less than that of U-235 but still good for our experiment.[[3]]

A boron coated GEM foil is being made by the company below http://n-cdt.com/

Another method uses BF3.

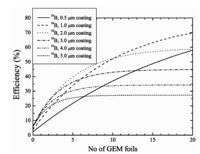

We are interested in a fissionable material coated onto the copper foils that is thin enough to allow the fission fragments to escape the foil and ionize the gas in the detector.

2.) Search for companies which use either sputtering or coating technology to apply the above material to caopper PCboards with hole int them such that the material does not fill up the hole. Hole diameter = ?

The material sputter onto the copper would have thickness on the order of Angstroms.

The TGEM PCboard would have a surface area of 10 cm x 10 cm.

3.) Current neutron efficiency plots for several detector

Media:NeutronDetectionEfficiency-vs-Energy_Ne-213_BaF.pdf

1/30/09

1.) Investigate if Thorium Oxide will be a good candidate for the fission chamber. You would use electrolysis to coat a TGEM board.

Ways to make thorium fission chamber

2.) Find reference for THGEM9, this was used to determine optimal THGEM design 2 years ago

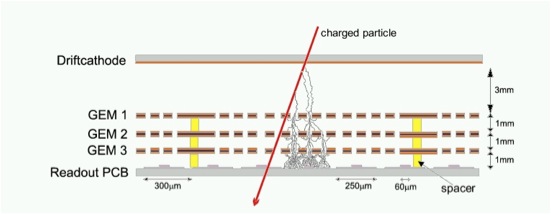

GEM-copper plate has dimensions of 3X3cm or 10X10cm with thinkness 5 micrometer copper layers.It has holes with diameter 60-80 micrometer.(From Operation of a triple GEM detector with CsI photocathode in pure BF4)

2/6/09

Thin deposition ThO2 molecular plating

2/13/09

Check if the people below can deliver Th coated Al or Cu sheets , coating thickness smaller than 5 micron, the thinner the better. http://www-wnt.gsi.de/tasca/

2/20/09

2.5 x 2.5 cm thorium coated TGEM cards coated by ISU chemistry.

chemistry Department cant not do the sputtering for safety purposes, they like to avoid radiation contamination.

Need a mask for the predrilled TGEM cards to prevent Thorium from entering holes

Radioactive waste procedure if we are allowed to sputter in chemistry.

Write report describing the process we want to do.

Radioactiving of Thorium may be a stumbling blog because of waste generated.

If we go for non-radioactive materials look up fission X-sect for Bismuth and Dysprosium

Fission cross section for Bi starts to be effective when the neutron energy is more than the range of interest.

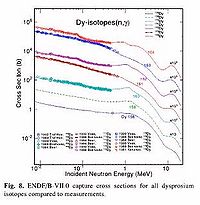

Dy-isotopes are very good for absorbing neutrons in the range between 0.01- 10 MeV.

References

Media:Shalem_MSthesis_march2005.pdf

http://www.ippe.obninsk.ru/podr/cjd/kobra13.php?SubentID=30974002

http://www.americanelements.com/thoxst.html

http://arxiv.org/pdf/physics/0404119

Media:NIM_A590_2008_pg134_Eberhardt.pdf Prep Targets

Neutron cross sections for different elements Media:Neutron_cross_sections.pdf