Difference between revisions of "2010"

(Created page with '=01/05/10= ;Simulation of the mass distribution spectra for Thorium-232 for 7.5 MeV: 100px 100px (…') |

|||

| (10 intermediate revisions by the same user not shown) | |||

| Line 1,027: | Line 1,027: | ||

The number of incident particles per Area = <math>\rho_{Th-232} V /A = \rho_{Th-232} L_{target} </math> | The number of incident particles per Area = <math>\rho_{Th-232} V /A = \rho_{Th-232} L_{target} </math> | ||

| − | <math>\rho_{ | + | <math>\rho_{U-238} = 19.1 g/cm^3 </math> |

<math>\Rightarrow 19.1 g/cm^3 \frac{1 mol}{238.029 g}\frac{ 6.02 \times 10^{23} Atoms}{mole} = 4.83 \times 10^{22}</math> | <math>\Rightarrow 19.1 g/cm^3 \frac{1 mol}{238.029 g}\frac{ 6.02 \times 10^{23} Atoms}{mole} = 4.83 \times 10^{22}</math> | ||

| Line 1,818: | Line 1,818: | ||

[[File:20_1.27_connector.jpeg || 250 px]] | [[File:20_1.27_connector.jpeg || 250 px]] | ||

| + | |||

| + | |||

| + | =Resistive paste thickness-mass calibration curve= | ||

| + | |||

| + | ;Aim | ||

| + | |||

| + | Studying the relationship between the mass and thickness of the resistive paste painted over 10X10 HTTGEM Foil. | ||

| + | |||

| + | ;Experiment equipments and restrictions: | ||

| + | |||

| + | Accurate scale (<math> \pm 0.1 g </math>), SEM (scanning electron microscope). | ||

| + | |||

| + | SEM sample's height limit : 5 cm. | ||

| + | |||

| + | (Dr. David Peterson Assistant Professor in Anthropology,Research Scientist, Center for Archaeology, Materials and Applied Spectroscopy (CAMAS) , 157 Graveley Hall,Idaho State University) | ||

| + | |||

| + | |||

| + | ;Procedure: | ||

| + | |||

| + | Measuring the mass of Prepared samples of 0.5 thickness FR4 square plates with different surface areas as in the table below before and after painting the paste. | ||

| + | |||

| + | Studying the paste distribution and thickness under SEM. | ||

| + | |||

| + | ;Experimental Data | ||

| + | |||

| + | {| border="1" cellpadding="4" | ||

| + | |- | ||

| + | | Plate Surface area (cm^2) (length <math> \pm 0.1 cm </math> ) || mass (g)<math> \pm 0.1mg </math> before applying the paste || mass (g)<math> \pm 0.1mg </math> after applying the paste ||<math>\frac{mg}{cm^2}</math> ||notes | ||

| + | |- | ||

| + | | 1.0X1.0 || 0.2627 || 0.2634 || 0.7|| paste on both sides | ||

| + | |- | ||

| + | | 2.0X2.0 || 0.9776 || 0.9793 || 0.4 || paste on both sides | ||

| + | |- | ||

| + | | 3.0X3.0 || 2.5074 || 2.5074 || 0 || paste on one side | ||

| + | |- | ||

| + | | 4.0X4.0 || 4.4923 || 4.4940 || || paste on one side | ||

| + | |- | ||

| + | | 5.0X5.0 || 7.3261 || 7.3250 || || paste on one side (paste is not uniform) | ||

| + | |} | ||

| + | |||

| + | |||

| + | |||

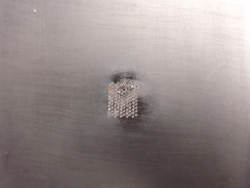

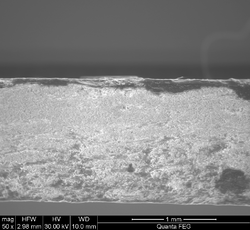

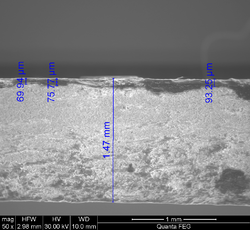

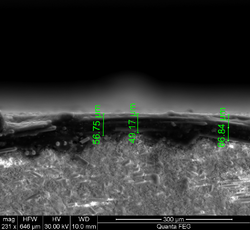

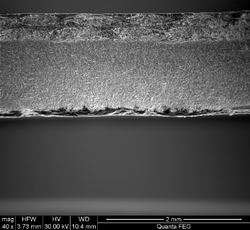

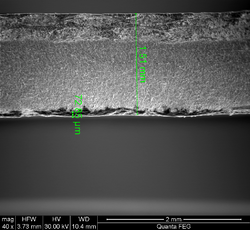

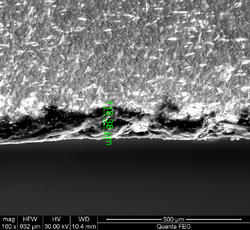

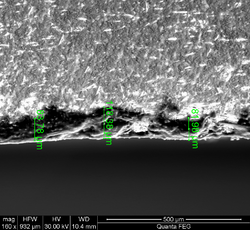

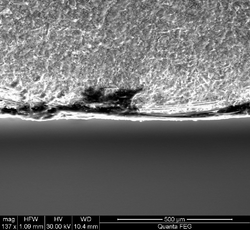

| + | ;SEM Images | ||

| + | |||

| + | ;2x2 sample | ||

| + | |||

| + | {| border="1" cellpadding="4" | ||

| + | | Image(a) ||Image(b) ||Image(c) || | ||

| + | |- | ||

| + | |[[File: 2X2.png |250 px]]|| [[File: 2X2_scale.png |250 px]] || [[File: 2X2_scale_zoom.png |250 px]] | ||

| + | |} | ||

| + | |||

| + | |||

| + | |||

| + | ;4x4 sample | ||

| + | |||

| + | {| border="1" cellpadding="4" | ||

| + | |Image(1) ||Image(2) ||Image(3) ||Image(4) ||Image(5) | ||

| + | |- | ||

| + | |[[File: 4x4.png |250 px]]|| [[File: 4X4_scale.png |250 px]] || [[File: 4X4_scale_zoom.png |250 px]] || [[File: 4X4_3scale_zoom_001.png |250 px]] || [[File: 4X4_scale_zoom_002.png |250 px]] | ||

| + | |} | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | ;Conclusions and Next step(s) | ||

| + | |||

| + | -Using SEM is accurate enough to measure the paste thickness within few micros depending on the HFW (horixzontal field width) value (determined for each image). | ||

| + | |||

| + | - Highly recommended to use a high precision scale for measuring the mass variation accurately for each samples, not only for this experiment but also for the future samples that will contain a radioactive materials. | ||

| + | |||

| + | - Preferable size for the best image is 2x2 cm with clean edges and reference line. | ||

| + | |||

| + | - The resistive paste thickness changes from one sample to another and is not unform surface within the micrometer scale, for the 4x4 sample maxmimum value measured or the paste thickness was 120 um, and the minimum was 80 um. Successivly, the 2x2 sample paste thickness was measured with a maximum of 66.84 um and mimimum 49.17 um. | ||

| + | |||

| + | - The measurements were accurate whenever the paste is distiguished from the over flow of the paste on the edge, and as the charging on the sample is the least. (When the sample was inside the SEM-chamber, a beam of electrons hit the sample and created charged areas that soemtimes ddi not make the edge image sharp enough, this is clear by comparing image (4) and image (5)). | ||

| + | |||

| + | - New samples will be prepared, all have the 2x2 cm^2 area, with a small groove on the edge to have new images by SEM, each sample will have a cerain amount of the resistitive paste, the mass of the paste accuratlely be determined (hopefully) using a high presicion scale. | ||

| + | |||

| + | ===Experiment Tasks timetable=== | ||

| + | {| border="1" cellpadding="4" | ||

| + | |- | ||

| + | | Date || Task || Notes | ||

| + | |- | ||

| + | | 10/20/10 || Preparing the samples in different areas || Done on time | ||

| + | |- | ||

| + | | 10/21/10 || painting and curing the paste, measuring the mass before and after painting the paste || measuring the mass is accurate enough, even we borrow the scale and put it in table without anything around and without being moved just for the day of the taking the data or finding a more accurate one in a more stable measuring conditions. | ||

| + | |- | ||

| + | |10/22/10 || studying the samples using SEM || CAMAS facility across Alvin Ricken Drive from the Idaho Accelerator Center, at 11:00 AM | ||

| + | |- | ||

| + | |10/28/10 || studying the 2x2 samples using SEM || (postpone) CAMAS facility across Alvin Ricken Drive from the Idaho Accelerator Center, at 11:00 AM | ||

| + | |- | ||

| + | |11/4/10 || studying the 2x2 samples using SEM || CAMAS facility across Alvin Ricken Drive from the Idaho Accelerator Center, at 11:00 AM ?? | ||

| + | |} | ||

| + | |||

| + | =12/15/10= | ||

| + | |||

| + | [[Insulators under a high voltage]] | ||

| + | |||

| + | |||

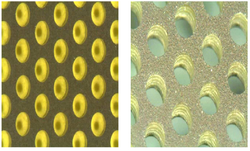

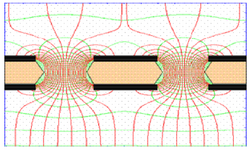

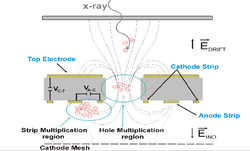

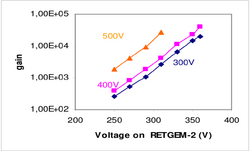

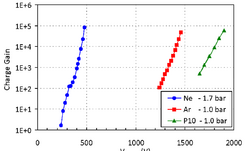

| + | =RETGEM vs. THCOBRA = | ||

| + | |||

| + | {| border="1" cellpadding="4" | ||

| + | |- | ||

| + | |RETGEM || THCOBRA | ||

| + | |- | ||

| + | |[[File: RETGEM_design.png |250 px]]|| [[File: THCOBRA_design.png |250 px]] | ||

| + | |- | ||

| + | |[[File: RETGEM_E-field.png |250 px]] || [[File: THCOBRA_E-field.png |250 px]] | ||

| + | |- | ||

| + | |[[File: REGEM_gain.png |250 px]]|| [[File: THCOBRA_gain.png |250 px]] | ||

| + | |} | ||

| + | |||

| + | =AFCRD Reports-2010= | ||

| + | |||

| + | ; Done in June (edited by 07/09/10) | ||

| + | |||

| + | 1.)The design for the THGEM-HV circuit is submitted to the board house. | ||

| + | |||

| + | 2.) Preparing the lab for a making samples and testing the THGEM foil. Preparation includes fixing the milling machine, and finding a vendor to provide the FR4 of thickness 1 mm, coated with 17 um copper from both sides. the size of the plate should be minimum 11X 11cm to fit the inside of THGEM-detector. | ||

| + | |||

| + | 3.) Finding a vendor to make THGEM foil : making 0.5 mm holes in certain pattern described in a CAD-file. | ||

| + | |||

| + | 4.) One of THGEM-foil is going to be covered by Th-232, a sample of Cerium (an stable element from the same group has close to TH-232 in physical properites) was used to test the mixing process with the paste. | ||

| + | |||

| + | 5.) Running the simulation using GEANT4 to calculate the fission cross for Th-232. | ||

| + | |||

| + | 6.) U-238 is going to be provided, it is going to be mixed with paste as in the same procedure done by Cerium to compare the detector characteristics with one based on Th-232. | ||

| + | |||

| + | 7.) Practicing repairing process for GEM-detector with Tamar. | ||

| + | ;Results: | ||

| + | |||

| + | a.) Improving the design of PC-board to hold up a voltage up to 10 kV without any sparking or short, also to include Geiger-mode APD circuit part if the idea get approved. | ||

| + | |||

| + | [[File:Direct observation of avalanche scintillations in a THGEM-based two-phase Ar avalanche detector using Geiger-mode APD.pdf]] | ||

| + | |||

| + | |||

| + | b.) The milling machine was sent to a repair shop in Boise, expected to start working by the end of next week from the date above. | ||

| + | |||

| + | c.) Still looking for a vendor to provide copper double clad FR4 with the same properties mentioned above. | ||

| + | |||

| + | d.)We got a Quote from a vendor to THGEM-foil but still we are waiting another two of them to compare, also checking if the vendor is able to deal with ones that has the radioactive materials. | ||

| + | |||

| + | e.) Simulation using GEANt4 needs to be improved compared with the experimental fission cross section provided by ENDF-data by creating a new ENDF-file to be a reference for GEANT4 for the Th-232 fission cross. | ||

| + | |||

| + | f.) To avoid accumulation of radioactive wastes, Nd (a stable element from the same group of U-238) will be mixed with the paste. | ||

| + | |||

| + | g.) Simulation for U-238 fission cross section started by 12 MeV energy and gave a 0.7b . | ||

| + | |||

| + | h.) Practicing on GEM gave an idea about required steps to finish THGEM-detector. | ||

| + | |||

| + | ;June | ||

| + | |||

| + | *Uranium Oxide has been chosen to dope the THGEM detector's resistive paste. Procedures are being developed to apply the dopant. | ||

| + | *A HV distribution board has been designed for the detector and will be procured by the end of July. | ||

| + | *The THGEM detector's ionization vessel has been machined to accommodate the above HV board. | ||

| + | |||

| + | ;Done in July (edited by 07/09/10) | ||

| + | |||

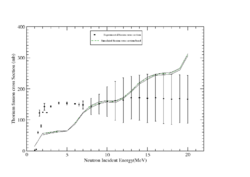

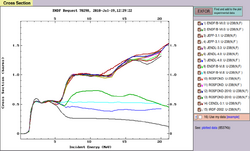

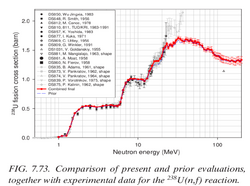

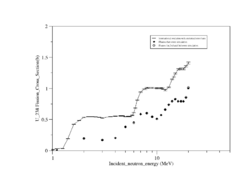

| + | A GEANT4 simulation of the 232Th(n,f) cross section from threshold to 20 MeV showed an increase with incident neutron energy but under-predicted the experimental results by a factor of 3 when the incident neutron energy was below 7 MeV. A simulation of 238U(n,f) under-predicted experiment by a factor of 2 for neutron energies below 5 MeV but was consistent with experiment above 5 MeV. | ||

| + | |||

| + | ;July | ||

| + | |||

| + | *A HV distribution board has been constructed and tested to sustain high voltages up to 9 kV. | ||

| + | *5 FR4 boards have been etched. Three boards were coated with resistive paste without dopant. 4 boards have been sent out for machining the 100 precision holes for preamplification. | ||

| + | |||

| + | |||

| + | |||

| + | ;August | ||

| + | |||

| + | *A set of 20 holes were machined in one of the FR4 boards etched last month in order to test for HV breakdown while waiting for the remaining FR4 boards to be machined by a vendor. | ||

| + | *A HV test of the above board showed a voltage breakdown at 2800 Volts when the board is immersed the detectors Argon C02 ionization gas. Other groups have shown that a high voltage of 1550 Volts was sufficient to operate similar detectors. The changes made to the board for this project should not impact the HV specification of 1550 Volts. The additional Voltage which is possible with our boards will serve to increase the detector gain. | ||

| + | |||

| + | ;September & October | ||

| + | |||

| + | *A set of 100 holes have been machined in each of the 5, 10X10 cm FR4 plates by the vendor. | ||

| + | *A test of the separation distance between the amplification board and grounded readout plane indicates that a distance of 2 mm is possible without discharges. | ||

| + | *The amplification stages need to be combined into a stack, tests are underway to determine the optimal separation distance between each amplification card in the stack. | ||

| + | |||

| + | ;November | ||

| + | |||

| + | * Detector amplification factors was studied, two Coated FR4 plates were placed to test the voltage applied on each plate and the distance between the FR4 plates, the aim was to get 2 kV between the top and the bottom of the FR4 plate Ar/Co2 gas. Until this point we are achieving about 1.7 kV in Ar/Co2 gas, 2.5 mm is the least distance between the plates. | ||

| + | |||

| + | * Improving the read out system by adding a VFAT adapter card. | ||

| + | |||

| + | =References= | ||

| + | |||

| + | [https://wiki.iac.isu.edu/index.php/Neutron_TGEM_Detector_Abdel#References] | ||

| + | |||

| + | [https://wiki.iac.isu.edu/index.php/Neutron_TGEM_Detector_Abdel Go back] | ||

Latest revision as of 15:05, 8 November 2011

01/05/10

- Simulation of the mass distribution spectra for Thorium-232 for 7.5 MeV

(1st figure is the full spectrum but the 2nd one for a>1)

Three kinds of events tracked :

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 1, Parent ID = 0

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm -80 cm 7.5 MeV 0 eV 0 fm 0 fm World initStep

1 0 fm 0 fm -5 mm 7.5 MeV 0 eV 79.5 cm 79.5 cm World Transportation

2 0 fm 0 fm -3.06 mm 0 eV 0 eV 1.94 mm 79.7 cm Target NeutronInelastic

:----- List of 2ndaries - #SpawnInStep= 3(Rest= 0,Along= 0,Post= 3), #SpawnTotal= 3 ---------------

: 0 fm 0 fm -3.06 mm 578 keV 1

: 0 fm 0 fm -3.06 mm 291 keV 1

: 0 fm 0 fm -3.06 mm 35.5 keV 231

:----------------------------------------------------------------- EndOf2ndaries Info ---------------

*********************************************************************************************************

* G4Track Information: Particle = Th231[14330.9], Track ID = 4, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm -3.06 mm 35.5 keV 0 eV 0 fm 0 fm Target initStep

1 251 um 2.7 mm 5 mm 35.5 keV 0 eV 8.5 mm 8.5 mm Target Transportation

2 2.43 mm 2.61 cm 7.5 cm 35.5 keV 0 eV 7.39 cm 8.24 cm World Transportation

3 3.17 mm 3.41 cm 9.87 cm 35.5 keV 0 eV 2.5 cm 10.7 cm Tracker StepLimiter

4 3.91 mm 4.2 cm 12.2 cm 35.5 keV 0 eV 2.5 cm 13.2 cm Tracker StepLimiter

5 4.65 mm 4.99 cm 14.6 cm 35.5 keV 0 eV 2.5 cm 15.7 cm Tracker StepLimiter

6 5.39 mm 5.79 cm 17 cm 35.5 keV 0 eV 2.5 cm 18.2 cm Tracker StepLimiter

7 6.12 mm 6.58 cm 19.3 cm 35.5 keV 0 eV 2.5 cm 20.7 cm Tracker StepLimiter

8 6.86 mm 7.37 cm 21.7 cm 35.5 keV 0 eV 2.5 cm 23.2 cm Tracker StepLimiter

9 6.98 mm 7.5 cm 22.1 cm 35.5 keV 0 eV 3.94 mm 23.6 cm Tracker Transportation

10 2.5 cm 26.9 cm 80 cm 35.5 keV 0 eV 61.1 cm 84.7 cm OutOfWorld Transportation

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 3, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm -3.06 mm 291 keV 0 eV 0 fm 0 fm Target initStep

1 -624 um -1.4 mm -5 mm 291 keV 0 eV 2.47 mm 2.47 mm Target Transportation

2 -25.6 cm -57.4 cm -80 cm 291 keV 0 eV 1.01 m 1.02 m OutOfWorld Transportation

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 2, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm -3.06 mm 578 keV 0 eV 0 fm 0 fm Target initStep

1 434 um -5 mm 811 um 578 keV 0 eV 6.34 mm 6.34 mm Target Transportation

2 6.94 cm -80 cm 61.6 cm 578 keV 0 eV 1.01 m 1.01 m OutOfWorld Transportation

- and

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 1, Parent ID = 0

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm -80 cm 7.5 MeV 0 eV 0 fm 0 fm World initStep

1 0 fm 0 fm -5 mm 7.5 MeV 0 eV 79.5 cm 79.5 cm World Transportation

2 0 fm 0 fm -2.2 mm 0 eV 0 eV 2.8 mm 79.8 cm Target NeutronInelastic

:----- List of 2ndaries - #SpawnInStep= 2(Rest= 0,Along= 0,Post= 2), #SpawnTotal= 2 ---------------

: 0 fm 0 fm -2.2 mm 1.91 MeV 1

: 0 fm 0 fm -2.2 mm 19.7 keV 232

:----------------------------------------------------------------- EndOf2ndaries Info ---------------

*********************************************************************************************************

* G4Track Information: Particle = Th232[5594.3], Track ID = 3, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm -2.2 mm 19.7 keV 0 eV 0 fm 0 fm Target initStep

1 -560 um -4.06 mm 5 mm 19.7 keV 0 eV 8.29 mm 8.29 mm Target Transportation

2 -6 mm -4.35 cm 7.5 cm 19.7 keV 0 eV 8.06 cm 8.88 cm World Transportation

3 -7.69 mm -5.58 cm 9.67 cm 19.7 keV 0 eV 2.5 cm 11.4 cm Tracker StepLimiter

4 -9.37 mm -6.81 cm 11.8 cm 19.7 keV 0 eV 2.5 cm 13.9 cm Tracker StepLimiter

5 -1.03 cm -7.5 cm 13.1 cm 19.7 keV 0 eV 1.42 cm 15.3 cm Tracker Transportation

6 -6.23 cm -45.2 cm 80 cm 19.7 keV 0 eV 77 cm 92.3 cm OutOfWorld Transportation

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 2, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm -2.2 mm 1.91 MeV 0 eV 0 fm 0 fm Target initStep

1 689 um 5 mm 2.07 mm 1.91 MeV 0 eV 6.61 mm 6.61 mm Target Transportation

2 11 cm 80 cm 68.1 cm 1.91 MeV 0 eV 1.05 m 1.06 m OutOfWorld Transportation

- In addition to the fission event

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 1, Parent ID = 0

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm -80 cm 7.5 MeV 0 eV 0 fm 0 fm World initStep

1 0 fm 0 fm -5 mm 7.5 MeV 0 eV 79.5 cm 79.5 cm World Transportation

2 0 fm 0 fm 1.2 mm 0 eV 0 eV 6.2 mm 80.1 cm Target NeutronInelastic

:----- List of 2ndaries - #SpawnInStep= 7(Rest= 0,Along= 0,Post= 7), #SpawnTotal= 7 ---------------

: 0 fm 0 fm 1.2 mm 138 keV 1

: 0 fm 0 fm 1.2 mm 2.37 MeV 1

: 0 fm 0 fm 1.2 mm 78.3 MeV 123

: 0 fm 0 fm 1.2 mm 1.83 MeV 1

: 0 fm 0 fm 1.2 mm 4.17 MeV 1

: 0 fm 0 fm 1.2 mm 653 keV 1

: 0 fm 0 fm 1.2 mm 89.1 MeV 105

:----------------------------------------------------------------- EndOf2ndaries Info ---------------

*********************************************************************************************************

* G4Track Information: Particle = Mo105[14330.9], Track ID = 8, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm 1.2 mm 89.1 MeV 0 eV 0 fm 0 fm Target initStep

1 5 mm 442 um 1.9 mm 89.1 MeV 0 eV 5.07 mm 5.07 mm Target Transportation

2 80 cm 7.07 cm 11.4 cm 89.1 MeV 0 eV 80.6 cm 81.1 cm OutOfWorld Transportation

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 7, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm 1.2 mm 653 keV 0 eV 0 fm 0 fm Target initStep

1 5 mm 1.85 mm 719 um 653 keV 0 eV 5.35 mm 5.35 mm Target Transportation

2 80 cm 29.7 cm -7.55 cm 653 keV 0 eV 85.1 cm 85.7 cm OutOfWorld Transportation

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 6, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm 1.2 mm 4.17 MeV 0 eV 0 fm 0 fm Target initStep

1 4.44 mm 1.75 mm -5 mm 4.17 MeV 0 eV 7.82 mm 7.82 mm Target Transportation

2 57.4 cm 22.6 cm -80 cm 4.17 MeV 0 eV 1 m 1.01 m OutOfWorld Transportation

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 5, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm 1.2 mm 1.83 MeV 0 eV 0 fm 0 fm Target initStep

1 2.07 mm 3.07 mm 5 mm 1.83 MeV 0 eV 5.31 mm 5.31 mm Target Transportation

2 4.01 cm 5.96 cm 7.5 cm 1.83 MeV 0 eV 9.77 cm 10.3 cm World Transportation

3 5.05 cm 7.5 cm 9.41 cm 1.83 MeV 0 eV 2.66 cm 13 cm Tracker Transportation

4 43.4 cm 64.5 cm 80 cm 1.83 MeV 0 eV 98.5 cm 1.11 m OutOfWorld Transportation

*********************************************************************************************************

* G4Track Information: Particle = Cd123[14330.9], Track ID = 4, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm 1.2 mm 78.3 MeV 0 eV 0 fm 0 fm Target initStep

1 -5 mm -1.83 mm 485 um 78.3 MeV 0 eV 5.37 mm 5.37 mm Target Transportation

2 -80 cm -29.3 cm -11.3 cm 78.3 MeV 0 eV 85.4 cm 86 cm OutOfWorld Transportation

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 3, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm 1.2 mm 2.37 MeV 0 eV 0 fm 0 fm Target initStep

1 -5 mm 328 um 1.75 mm 2.37 MeV 0 eV 5.04 mm 5.04 mm Target Transportation

2 -80 cm 5.25 cm 8.89 cm 2.37 MeV 0 eV 80.1 cm 80.7 cm OutOfWorld Transportation

*********************************************************************************************************

* G4Track Information: Particle = neutron, Track ID = 2, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 0 fm 0 fm 1.2 mm 138 keV 0 eV 0 fm 0 fm Target initStep

1 5 mm 2.66 mm 3.68 mm 138 keV 0 eV 6.18 mm 6.18 mm Target Transportation

2 80 cm 42.6 cm 39.9 cm 138 keV 0 eV 98.3 cm 99 cm OutOfWorld Transportation

- Voltage Measurements when the THGEM resistor is 30 Mohm in [1] fig.3

| (kV) 0.001 | (kV) 0.001 | (kV) 0.001 | (kV) 0.001 |

| 1.058 | 0.410 | 0.403 | 0.394 |

| 2.057 | 0.798 | 0.780 | 0.763 |

| 3.020 | 1.169 | 1.145 | 1.120 |

| 4.021 | 1.557 | 1.524 | 1.492 |

| 5.066 | 1.961 | 1.920 | 1.879 |

| 6.080 | 2.353 | 2.302 | 2.253 |

| 7.041 | 2.721 | 2.662 | 2.607 |

| 8.094 | 3.122 | 3.058 | 2.989 |

| 9.065 | 3.495 | 3.420 | 3.346 |

| 10.120 | 3.896 | 3.814 | 3.733 |

| 11.135 | 4.281 | 4.192 | 4.097 |

| 12.032 | 4.619 | 4.520 | 4.422 |

| 13.017 | 4.992 | 4.883 | 4.760 |

01/11/10

- HV circuit

The table below shows the voltage measurements for the HV circuit represented by fig.3 [2] with THGEM-resistor is 180 Mohm. The input voltage choice is based on the maximum voltage capability of the available power supplies in LDS until the date above.

| (kV) 0.001 | (kV) 0.001 | (kV) 0.001 | (kV) 0.001 |

| 1.030 | 0.087 | 0.800 | 0.790 |

| 4.005 | 3.158 | 3.100 | 3.066 |

| 5.010 | 3.949 | 3.887 | 3.836 |

| 8.009* | 6.300 | 6.214 | 6.136 |

*Expected a higher voltage measurements for THGEM resistors closer to the voltage of source if THGEM resistors are replaced by resistor of 250-300 Mohm.

1/22/10

1.) Paste practice

The paste was applied on a G-10 that has 1 mm hole diameter and 0.5mm and 1mm pitch. After curing the paste made a solid surface on the top on the G-10 surface without penetrating through the holes or dropping on the carrier.

insert picture

insert resistance measurements

insert voltage difference measurements

Next paste practice.

Apply paste to PC board without drilling holes. Try to get copper layer for connections. Don't worry about PC board thickness

Order FR4 boards clad on both sides with copper that are the same thickness as the ones in the paper.

2.) HV distributions

What happens when a 30 mv pulse is pushed onto the ground plane. Do you see it through the capacitor?

3.) GEANT4 simulation:

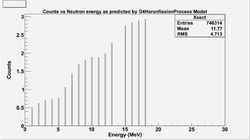

A fission fragment distribution from Th-232 was observed. Now working on X-section.

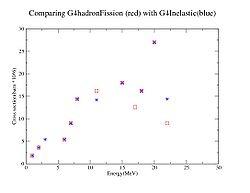

A new physics model was installed and is working called "G4HadronFission".

The goal is to compare this model with "G4Inelastic".

Which one reproduces cross section?

Table with data from measurements.

http://www.nndc.bnl.gov/exfor/endf.htm

02/12/10

- ED-7100 picture

insert resistance measurements

insert voltage difference measurements

Next paste practice.

Apply paste to PC board without drilling holes. Try to get copper layer for connections. Don't worry about PC board thickness

- Order FR4

Order FR4 boards clad on both sides with copper that are the same thickness as the ones in the paper. There are the following kinds of laminates that we can use for the TGEM:

| Laminate | Dielectric Constant (</math> (kV) 0.05) | The Least Thickness (mm) |

| RO4003C | 3.38 | 0.101 |

| RO4350B | 3.48 | 0.203 |

| RO3035 | 3.5 | 0.13 |

| RO3003 | 3.00( 0.04) | 0.13 |

| RO3006 | 6.15( 0.15) | 0.13 |

| RO3010 | 10.2( 0.3) | 0.13 |

| RO4360 | 6.15 ( 0.15) | 0.203 |

| Theta | 3.9-4.01(without uncertainty) | 0.056 |

It is possible also to have copper on the chosen laminate with 17 um thickness. the laminate thckness last update is available on the following:File:Standard Thicknesses, Tolerances and Panel Sizes.pdf

Based on a call done by 02/11/10:

1- The company can provide us with 30 mil (0.76 mm) and 40 mil (1.02 mm) FR4 thickness plates.

2- The minimum copper thickness is 17um which is equivalent to 1/2 oz.

3-The prices are as the following

| FR4-Thickness | Copper thickness(um) | price per 12"X18" plate(305X457mm) (us $) | expected laminate series |

| 30 mil (0.76 mm) | 17 | 70.17 | 3003 |

| 40 mil (1.02 mm) | 17 | 99.01 | 3003 |

| 9 | 99.01 | 5880 |

Please note:

1- Expected change in pricing whenever you call for order but this is just an estimation.

2- The price of the copper double sided is the same as one-sided ones ??

3- the order would be ready within 2 weeks from the date of order.

4- for non-standard thickness, the customer is expected to buy the whole yeild. (usually is 6 plates but not always!)

5- the minimum order is 150$.

6- Copper single sided or double sided is possible depending on the thickness of the chosen laminate.

For ordering : call Melody on (480-961-8249) who is a busy lady as described (do not be upset if you have to leave a voicemail) or call 800-227-6437 for any additional information on their products.

- Important

The order can not be by individuals, the faster way is to make under the university name in a formal paper which determines exactly what we want, Melody is helpful and ready to answer any question such that we will sure 100% of every small detail.

2.) HV distributions

What happens when a 30 mv pulse is pushed onto the ground plane. Do you see it through the capacitor?

- GEANT4 simulation

there are two classes that can simulate the Th-232 fission process,

a- G4InelasticProcess . [[3]] b- G4HardronFission. the following should be added to the ExN02PhysicsList.cc :

A fission fragment distribution from Th-232 was observed. Now working on X-section.

G4InclAblaCascadeInterface *theModel = new G4InclAblaCascadeInterface();

theModel->SetMinEnergy(0.0 * GeV);

theModel->SetMaxEnergy(3.0 * GeV);

G4HadronFissionProcess *theFissionProcess = new G4HadronFissionProcess();

theFissionProcess->AddDataSet(new G4NeutronHPFissionData());

theFissionProcess->RegisterMe(theModel);

pmanager->AddDiscreteProcess(theFissionProcess);

To compare this model with "G4Inelastic", the simulation is run for just a 100 neutrons, ExN02SteppingVerbose.cc can distinguish between a reaction of one fission fragment (dominant) or two fission fragments(used for calculating the fission cross section for Th-232).

The previous figure is based on the following calculation.File:Xsection cal.txt

Which one reproduces cross section?

Table with data from measurements.

http://www.nndc.bnl.gov/exfor/endf.htm the website helps to generate graphs depending on the data-libraries stored. after you choose your element you can plot and add more data to your plot. the previous plot for the Th-232 is generated by the same website.[[4]]

2/16/10

1.) Cross section from Simulation

Th-232 is a cube 10 x 10 x 10 cm^3.

The number of incident particles per Area =

X-sect =

- barns

2.) Output a file with fission fragments events containing energy and momentum for each fragment as well as incident neutron energy

3.) Check on status of Additive T

4.) Order FR4 to make GEm foils

FR4 thickness is 1 mm = 30 mil with a standard copper thickness 17 microns ( half ounce). = model 3003

call Melody on (480-961-8249) who is a busy lady as described (do not be upset if you have to leave a voicemail) or call 800-227-6437 for any additional information on their products.

$200 , 30 mil , 3003 series 1/2 x 1/2 oz

5.) Insert table with power through resisters in HV circuit. This will determine if the resisters can sustain the voltage. Afterword , short the GEM foil connection and determine change in power requirements.

6.)Measure voltage difference for several points across front and back of board coated with resistive paste.

02/22/10

- Th-Fission Simulation

The following table represents the fission products and their physical parameters for Th-fission process that covers the range 22-12 MeV.

| Neutron Kinetic Energy (MeV) | Atomic Number | Atomic Mass | Kinetic Energy(MeV) | (N/s) | ||

| 22 | 47 | 118 | 79.313 | 1047.05 | -2848.8 | -2866.72 |

| 22 | 43 | 105 | 91.7065 | -80.3602 | 3421.92 | -2493.52 |

| 20 | 47 | 117 | 80.9944 | -3948.01 | -1374.8 | -413.714 |

| 20 | 47 | 117 | 80.9944 | -3948.01 | -1374.8 | -413.714 |

| 17 | 43 | 108 | 85.0977 | 2021.82 | 3575.92 | 491.487 |

| 17 | 47 | 119 | 78.2587 | 3372.27 | -2402.48 | -446.444 |

| 15 | 43 | 110 | 83.1197 | 3527.28 | -2094.98 | -442.242 |

| 15 | 47 | 118 | 81.6169 | -2762.52 | -3144.03 | -645.413 |

| 12 | 43 | 110 | 83.6868 | 233.754 | -2554.97 | -3249.9 |

| 12 | 47 | 118 | 80.4392 | -417.031 | 2668.67 | 3221.85 |

Events look good now make a text file with all information about event on one line (neutronEin,Afrag1,Afrag2,Zfrag1,Zfrag2, Efrag1,Efrag2,Pxfrag1,Pxfrag2...)

- HV-circuit Pwer Measurements

| Voltage (kV)( 0.001) | Current( 1 uA) | Power (W) |

| 0.500 | 8 | 0.0013 |

| 1.000 | 14 | 0.0039 |

| 1.500 | 21 | 0.0088 |

| 2.000 | 27 | 0.0146 |

| 2.500 | 33 | 0.0218 |

| 3.000 | 40 | 0.0320 |

| 3.500 | 46 | 0.0423 |

| 4.000 | 53 | 0.0562 |

| 4.500 | 60 | 0.0720 |

| 5.000 | 66 | 0.0871 |

| 6.000 | 80 | 0.1280 |

| 7.000 | 91 | 0.1656 |

| 8.000 | 104 | 0.2163 |

Availability 2.5W : 200 Mohm [5], 300 [6], 400 [7] , 500 [8]

03/05/10

A 1"X1" laminate was shorted to around 1kV after following the preparing procedure below. The difference in voltage between the two surfaces is 869 V over all the paste area (I tried to make it as thin as possible and had the whole free copper free covered with a little contact to the copper frame), the board starts to spark when the voltage raised up to 2 kV.

I would suspect that the short is due to the copper at the outside edge of the laminate. You should smooth the surface using sandpaper. Perhaps we may even need to etch the outer edge copper away from the edge.

Yes, That was the reason, I removed the copper close to the edge, I succeeded to to reach 5k without sparking. I am now in process to repeat the experiment but the copper on the edge will be removed by the etching solution leaving just a little frame for connection.

- 3000series laminate preparing procedure

1- Get a laminate with a desired dimensions etched by copper etchant solution after covering part of it to form a copper frame.

2- Paste the ED-7100 to free free copper area with a little contact with the frame.

3- Cure the paste.

4- Short the laminate with a power source.

03/09/10

- HV circuit

The TGEM-plate was connected to the circuit, the source voltage was 1kV, but still the current is passing through the circuit where .

1.) Insert Fission Fragment plots for different neutron energies.

2.) Run simulations for neutron energies between 1 and 20 MeV, 1 MeV steps.

3) Plot X-sect.

4.) Construct PCB GEM cards and insert into HV network. Measure Current and Voltage to determine power.

5.) Drill 5 holes into one of the GEM cards and determine voltage for sparks.

- Thorioum like material

An email is sent to Dr.Patricia (Patricia.Paviet-Hartmann@unlv.edu) about a Thorium like materially physically and chemically, she suggested to use Cerium oxide(IV). I contacted chemistry material shop they said there is but it is very little, a call is needed to Mark to make an order.

safety datasheet [9]

- RF-Connectors and adapters

The best prices founded on [10] Please look at the top of the blue box, there is a line where you can find what they offer.

03/30/10

- HV Circuit

1.) Using the new resistance 300 Mohm the current still runs throught the circuit.

| (no 4.7 M resistor) | |||

| 1.000 | 10 | 0.220 | 0.220 |

| 2.000 | 18 | 0.493 | 0.440 |

| 3.000 | 27 | 0.734 | 0.654 |

| 4.000 | 36 | 0.983 | 0.874 |

| 5.000 | 45 | (higher than 1.1kV) | 1.084 |

The difference between the 3rd column and 4th column measurements is one of THGEM1 has a 4.7 Mohm resistor disconnected.

2.) The design for for one of the THGEM circuit lines is created by eagle,the bottom picture shows only the board within only the available space (3cm X 13cm). Unfortunately the space for the ciruit board that is available now is not enough, a new cavity will be engraved on the other side and its size is big as 6cm X 20cm X enough height to havethe resistors inside.

- Paste and the new laminate

the paste is applied on the laminate by etching all the copper on both side leaving a copper frame with 0.2cm width only away from edge 0.5cm. Successes achieved in following :

a) Sharpie perminent is the best for covering the copper to keep it on the desired shape on the laminate.

b) No sparking on the on the laminate surface (without holes) that is etched and covered with the paste unless the voltage is higher that 9 kV.

Still the work is continuing to test the same laminate dimensions covered with the paste but with a certain number of holes on its surface.

- Simulations

A simulations were run for the TH-232 fission fragment using abla interface with hadron fission model and InelasticProcess model.

The two models are giving the same results.

04/09/10

- Sparking Test

A new laminate is cut and covered by resistive paste, a number of holes are created in pattern close to that of THGEM (but the distances are not the same among the holes as those in the pattern). The test led to the following conclusions:

1- The laminate passed 3kV, it started to spark after that value since the design has some defects, a perfect design by the CNC-machines will help to pass this value easily.

2-The distances among the holes is very important, even after applying the resistive paste, the further from each other is the better to avoid sparking.

3- Adding Cerium to the paste has not any effect on the paste resistivity.

4-The new laminate is softer than the the G-10 that was used before, attention to not to bend it specially after the design, the holes will make it easily damaged under a little strong hand pressure on any side, for a better efficiency, the surface needs to be flat.

04/20/10

1.) order HV boards ( a.) print out full scale version and check fit, b.) determine places to mill, c.) check max size of PCboard sheet)

2.) HV test copper GEM PCboards. apply paste to reduce sparking

3.) Run GEANT4 programs on all available computers

4.) Dr. Brey has U-238, can we have it and destroy it?

5.) Solution for making more TGEMs.

a.) Design in CAD and ship to CNC place? b.) apply paste before or after drilling? (Th-232 doped paste is a contamination hazard.) c.) Paste application method (Printer or brushes)

05/4/10

1.) order HV boards

( a.) print out full scale version and check fit,

Done, waiting for Dr. Forest to inspect

b.) determine places to mill,

currently have a milled area for HV which is 10cm x 3 cm. We need to create a 13 x 8 cm area to hold the above design.

c.) check max size of PCboard sheet)

2.) HV test copper GEM PCboards. apply paste to reduce sparking

Machine 4 mini-TGEMs.

3.) Run GEANT4 programs on all available computers

put G4 runs on Brems

4.) Dr. Brey has U-238, can we have it and destroy it?

5.) Solution for making more TGEMs.

a.) Design in CAD and ship to CNC place?

Free CAD drawing exists

b.) apply paste before or after drilling? (Th-232 doped paste is a contamination hazard.)

Paste then drill. Need to take care of radioactive waste.

c.) Paste application method (Printer or brushes)

Order Ink Jet printer which will work with DAQ machine (Unix) then practice.

05/18/10

1.) Finish laying out HV design.

currently have a milled area for HV which is 10cm x 3 cm. We need to create a 13 x 8 cm area to hold the above design.

a.) check max size of PCboard sheet)

maybe 11" x 18" we can get HV board on there no problem. Now optimize number of boards per 11" x 18" PC board.

b.) Insert picture in wiki with paper representing PCboard sizes layed on top of detector.

c.) Get some quotes

2.) Machine 4 mini-TGEMs.

check out moving drill press to mill machine table.

Build collar for drill bit.

3.) Run GEANT4 programs on all available computers

put G4 runs on Brems

http://wiki.iac.isu.edu/index.php/Running_With_Slurm Batch jobs on Brehms

Install Ionization for ion fragments.

Plot current results using inca and DAQ computer with error bars.

4.) Dr. Brey has U-238, can we have it and destroy it?

5.) Solution for making more TGEMs.

Advanced Circuit did the copper TGEMS, will they do another coated with Th-232. I doubt it.

a.) Send CAD drawings to Advanced Cicuits for quotes. A CAD design exists, need to quality control check it, can a vendor read it? Remember copper only around perimeter.

b.) Is there a vendor willing to drill.

Paste then drill. Need to take care of radioactive waste.

Need to develop method to apply doped paste to circuit board with holes.

Look for plastic plugs to go into the holes.

c.) Paste application method (Printer or brushes)

Order Ink Jet printer which will work with DAQ machine (Unix) then practice.

4/06/10 (HV-circuit Design)(Ionization)

1.) Finish laying out HV design.

currently have a milled area for HV which is 10cm x 3 cm. We need to create a 13 x 8 cm area to hold the above design.

a.) check max size of PCboard sheet)

maybe 11" x 18" we can get HV board on there no problem. Now optimize number of boards per 11" x 18" PC board.

b.) Insert picture in wiki with paper representing PCboard sizes layed on top of detector.

c.) Get some quotes

The PC-boards design is done, Gerber files are also created and submitted to the Board house (Circuit Graphics [11]). I am waiting for the price.

2.) Machine 4 mini-TGEMs.

check out moving drill press to mill machine table.

Build collar for drill bit.

I made a visit to milling workshop in the university, they checked for me the milling machine in the beam lab, they advice me to check the utilities to check the electric connections (I asked Sanda to have maintenance request to check the connections), the machine now is ok and everything is working ok except for :

1- Electric lever key that takes the table up and down needs to be replaced.

2- The drill has a strange sound when it runs slow, but it is good as it runs fast.

3- The data reader is not working (important for small displacements).

In the utilities Department there is a technician (Paul (Dee) Rasmussen x2694 ) who used to do all the maintenance for the CNC and milling machines the milling lab, I asked the department to submit a maintenance request to check and try to fix the above in our machine. (an email is sent to you describes what is needed to go further in this).

I borrowed an adapter to catch very small drill bit, it works manually to avoid breaking the bit. Also I visited General products (tools shop) to buy 0.4 mm drill bit and an adapter to catch it . I tried more than once to use this drill bit to get holes on TGEM plate, it is working good but there are still some difficulties in the displacements, I hoping the situation will be much better after fixing the data reader.

Bridgeport Series I Milling Machine

Brian Denny at Asi Machine & Supply - www.asimachine.com (208) 888-9236 will come by and give us a cost repair estimate when he or a fellow worker is in the area.

Brian Bishop is the Asi rep which travels to ISU frequently (one a month). His Cell number is 208-573-1765. The best repair tactic is to remove the head and ship it to Boise. Or if not in a hurry, wait for Brian to come back to town and he will take it back with him.

3.) Run GEANT4 programs on all available computers

put G4 runs on Brems

http://wiki.iac.isu.edu/index.php/Running_With_Slurm Batch jobs on Brehms

Install Ionization for ion fragments.

Find a measurement to compare the ionization of the gas to. A light or heavy ion traveling through as gas chamber liberates ? electrons by ionization.

GEANT4 is running with the ionization, the chamber material now is Ar 90 \percent with 10 \percent CO2.

Both ExN02DetectorConstruction.cc and ExN02PhysicsList.cc were edited as the following:

To add ArCO2 mixture:

G4Material* ArCO2=new G4Material("ArCO2",density,ncomponents=2);

ArCO2->AddMaterial(Ar,fractionmass=90*perCent);

ArCO2->AddMaterial(CO2 ,fractionmass=10*perCent);

To track the fission fragments:

else if( particleName == "alpha" ||

particleName == "He3" ||

particleName == "GenericIon" ) {

//Ions

//pmanager->AddProcess(new G4hMultipleScattering, -1, 1, 1);

pmanager->AddProcess(new G4ionIonisation, -1, 2, 2);

}

The text file contains:

En FF1A FF1Z FF1P px py pz FF1Range chargeFF2A FF2Z FF2P px py pz FF2Range charge 1 107 43 0 0 -0 -0 3.15298 43 121 47 0 0 0 0 2.97138 47 1 121 47 0 0 -0 0 2.97565 47 107 43 0 -0 0 -0 3.10325 43 1 97 38 0 0 0 0 3.63527 38 133 52 0 0 0 -0 2.85036 52 1 89 35 0 0 0 0 3.95635 35 141 55 0 -0 -0 -0 2.78145 55 1 90 35 0 0 0 0 3.94515 35 140 55 0 0 -0 -0 2.7865 55 1 95 38 0 -0 -0 -0 3.67254 38 135 52 0 -0 -0 0 2.88728 52 1 119 47 0 0 0 0 2.98623 47 109 43 0 0 0 -0 3.17545 43 1 93 37 0 0 -0 0 3.78905 37 137 53 0 0 -0 -0 2.8152 53 1 129 50 0 -0 -0 0 2.92961 50 101 40 0 0 0 -0 3.46852 40 1 91 36 0 -0 0 0 3.8446 36 138 54 0 0 -0 -0 2.80753 54 1 99 40 0 -0 0 0 3.52113 40 131 50 0 -0 0 -0 2.96041 50 1 89 35 0 -0 -0 -0 3.86209 35 141 55 0 0 -0 0 2.7893 55 1 106 42 0 -0 -0 -0 3.16644 42 123 48 0 -0 -0 0 2.96203 48 1 93 37 0 0 0 0 3.65556 37 137 53 0 0 0 -0 2.81346 53

Ionization and Number of the the electrons produced

I am now running on brems to get the range for each fragments in the gaseous mixture described for 4MeV,8MeV,12MeV,16MeV and 20MeV. I am thinking to get a graph for different fragments ranges as function of the atomic number with error bars.

Brian told me that I am still running the processes in sequence, not becuase of any mistake I did but looks he needs to update the system and work on that point.

Submitting the 50 jobs together failed if I have script that contains all the commands for submitting 50 jobs. Brian and I will work on this to get it done after the system runs my jobs in parallel.

Plot current results using inca and DAQ computer with error bars.

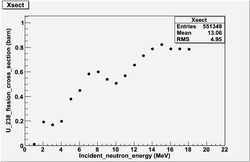

E, Sim X-sect, Measured X-sect, Ratio

4.) Dr. Brey has U-238, can we have it and destroy it?

5.) Solution for making more TGEMs.

Advanced Circuit did the copper TGEMS, will they do another coated with Th-232. I doubt it.

a.) Send CAD drawings to Advanced Cicuits for quotes. A CAD design exists, need to quality control check it, can a vendor read it? Remember copper only around perimeter.

b.) Is there a vendor willing to drill.

Paste then drill. Need to take care of radioactive waste.

I am in process to contact "General product", which cares about milling and CNC machines, I talked to them on the phone to take an appointment(there here in Pocatello) then I will give a report summarizes the meeting and what they do for us.

General Products, 3661 Pole line Rd. , tel: 208-237-2390.

Need to develop method to apply doped paste to circuit board with holes.

Look for plastic plugs to go into the holes.

c.) Paste application method (Printer or brushes)

Order Ink Jet printer which will work with DAQ machine (Unix) then practice.

I am still in process to find an appropriate printer, most of the surface screen printers that I found are for cloth, or even has a special paste that you you should use for the printer. I am also keeping an eye on the website you sent me [12] and there are a new printer there that it might be a choice but I did not get the answers for the questions I sent yet.

- Info about Linx 4100

To answer your questions, this system will come with a manual, and it uses 0.5 liter cleaning solvent and ink cartridges.

The three common ink types are fast dry, which is a methyl ethyl ketone solvent base, ethanol, which is an ethyl alcohol base, and water, which is a simple water base. Please note that the cleaning solvent must match the ink being used.

Also, this system has its own central printing unit, which includes the ink system, controls and display, and does not have the ability to be connected to an external computer; the only ports on it are an external alarm connector and photocell & shaft encoder sockets.

- Info about AMI Presco 465 Compact Screen Printer

This system will come with a manual, and it uses thick film paste-like ink that must be introduced using a plastic spatula.

Further, the squeegee blade in this system should be buttered with some of this ink to eliminate friction between the blade and the screen on the initial pass.

Also, this system has no interface for external PC control, and utilizes onboard microprocessor PLC control.

06/15/10

Quote for HV-PCBoard

the following link for the gerber files sent to the vendor. [13]

Board has been ordered will arrive Monday June 21, 2010

Detector machined

The detector has been machined to house the new HV boards.

called Lloyd

Ultimatum has been given by upper management to get rid of the material.

Call Lloyd (Mobile: 865-206-9663) late Thursday if you don't hear from him. He is gone for 3 weeks after next friday.

TGEM manufacturing

Collet for Milling machine ordered

$54 was paid for a collet which can hold a 1/64" drill bit to drill TGEM holes into FR4. We have at least 2 drill bits.

General Products has been asked to give a quote for producing 10 x 10 cm sized Thick GEM foils. The will build a frame holder for the TGEM boards to hold them while they CNC machine. The boards are thin and flexible needed support from the frame. General products is willing to talk about how they can mill a Thorium doped TGEM.

Simulating the ionization of the fission fragments

Simulated -vs- Experiment X-sect results

Take ratio of measured X-sect/Simulated X-sect and put it in a table

| Energy (MeV) | Experimental fission cross section(mb) | Simulated fission cross section(mb) | (Experimental fission cross section/Simulated fission cross section) |

| 1 | 0.0700 | ||

| 2 | 2.20 | ||

| 3 | 2.24 | ||

| 4 | 2.44 | ||

| 5 | 2.3 | ||

| 6 | 1.7 | ||

| 7 | 1.2 | ||

| 8 | 1 | ||

| 9 | 0.97 | ||

| 10 | 0.99 | ||

| 11 | 1.03 | ||

| 12 | 0.95 | ||

| 13 | 0.89 | ||

| 14 | 0.79 | ||

| 15 | 0.72 | ||

| 16 | 0.60 | ||

| 17 | 0.68 | ||

| 18 | 0.66 | ||

| 19 | 0.64 | ||

| 20 | 0.54 |

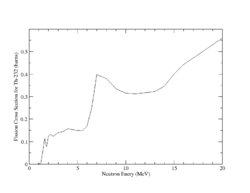

The error estimation is based on the following fission xsection graph:

Find original source for Fission model in GEANT4 and make your own copy which you place in you subdirectory.

- ENDF abbreviations

(n,f): neutron fission reaction, cross section is considering the probability for 1st chance , 2nd chance, ..., n chance fission for the target.

(n,f '): 1st chance neutron fission reaction

For our simulation we consider only the fission reaction of parent ID = 1, so only we are considering first chance fission reaction only.

Fragment ionization

Please look at the following link : [14]Ionization_and_Number_of_the_the_electrons_produced

- The Visit To General Products

the visit was successful in a way that they understood what we want to do, I sent a cad-file, and they sadi that there are able to do it. Also I talked ot him about Th-coated THGEM-plate drilling, he said he will be able basically to do it but he needs to know how are we going to do it and the procedures that we are going to take as radiation protection. He will email me with a quote for the first step, but still he needs to think more about Th-coated ones.

06/28/10

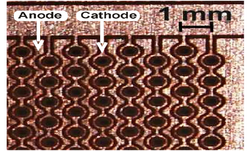

HV board stuffed

The resistors were soldered onto the HV boards.

Below is a picture of the circuit and a measurement of the Voltage acccorss each TGEM as a function of the total voltage.

Now put ONE TGEM card onto the HV circuit and determine the voltage which causes a discharge in Air.

Th-232

Lloyd has found someone to pay for shipping us the Th-232 BUT Dr. Wells has offered 10 g of U-238 for us to use. Dr. Forest will try to meet with him this week to facilitate the transfer. U-238 has 3 times for cross section then Th-232 when neutron energy is between 10 and 15 MeV.

Alan Hunt may still be interested in getting the 1.7 kg material.

TGEM Machining

The 76-drill bit seems to not produce holes in a straight line on the milling machine even though larger drill bit (1/32) did make straight lines. We suspect the drill bit deflects too much when pressure is applied for drilling the hole.

Try to "hole punch" the material before drilling so the drill bit does not move around on the material before it has a chance to start drilling the material.

Simulation

Brems appears to be up try an submit jobs to fill in the X-sect energy gaps.

Then try one energy for U-238.

- Cross section from Simulation

U-238 is a cube 1 x 1 x 1 cm^3.

The number of incident particles per Area =

X-sect =

- barns

(target length was 1 cm)

Add errors to experimental data in table above.

07/26/10

The circuit board is populated and tested, it reaches now to 8 kV without sparking.

The old TGEM foil is also tested, it starts sparking when the voltage reached 400 V on it.

08/1/2010

- TGEM-foil Preparation

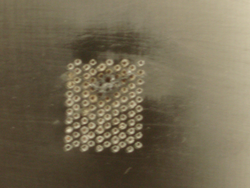

FR4 is cut into 11x11 cm, the trial foil has 100 holes, the paste inside the area surrounded by copper (yellow) as in the figure.

8/10/2010

1.) Machine 10 x 10 cm boards so we have 100 holes in a 1.3 x 1.3 cm square array centered on the 10 x 10 cm boards.

3 boards will have resistive paste and 2 will have no paste.

at $20 each we are expecting at least a $100 charge for milling the test boards.

1 10 cm x 10 cm board with a 3.5 mm wide copper outer trace has been made, 4 more are needed.

2.) Search for Panasonic connector samples continues

3.)U-238 articles reporting fission measurements on interlibrary loan.

8/23/2010

1.) 5 , 12 x 12 cm FR4 boards have been etched with a outer copper trace that is 3.5 mm wide. 3 of the boards have been coated with resistive paste. The machine shop will drill 100 holes in each of the 4 boards and treat the 5th board as a spare.

Get a time estimate for drilling holes from Vendor.

Still waiting the quote. expected in the quote: *fixture price. *cost of drilling holes for 100 *cost for drilling all the holes in 10X10 cm *cost of labour

2.) Allied electronics may be willing to sell us 25 connectors. WIP

Quote is sent, $167.88 each for min order of 25 and both connectors, 25 connector pairs for $350. 2-3 weeks delivery.

3.) Insert paper reference that you received here.

File:Pankratov fxsection Th232 U233 U235 Np237 U238 5-37MeV.pdf

the over all accuracy in the measurements (f_x-section) in the range 5-27MeV was not less that 5 percent, but worse than 10 percent in the range 27-37 MeV.

Use data Thief to make your own version of Figure 6, with you simulation results overlayed, and legend includes reference.

The previous data measurements only seem high in the range 20-37 MeV (ref. File:Ignatyyuk U238 nxsetion upto150MeV.pdf page 5).

Also create Xmgrace version of U-238 X-sect with your simulation result and the red line average from above overlayed.

What is mistake for E=3 MeV U-238 simulation?

4.) Drill holes into the TGEM chamber to mount the HV boards

5.) Simulation Cross Section

What is the Format of the the cross-section files GEANT4 uses for Fission.

There is not any information online about the format of the files, in addition there are not editable by users, still users can leave a request on the forum! [15]

Are these files stored in

data/G4NDL3.13/Fission/CrossSection

looks that files are saved without any extension.

8/30/2010

1.) Vendor will likely be able to finish the drilling of 100 holes in 4 FR4 plates 2 weeks after the quote is accepted. A fixture will need to be built to hold the FR4 boards in order to drill the holes at the same location on each board.

2.) Allied electronics may be willing to sell us 25 connectors. WIP

Quote is sent, $167.88 each for min order of 25 and both connectors, 25 connector pairs for $350. 2-3 weeks delivery.

3.) Insert paper reference that you received here.

File:Pankratov fxsection Th232 U233 U235 Np237 U238 5-37MeV.pdf

the over all accuracy in the measurements (f_x-section) in the range 5-27MeV was not less that 5 percent, but worse than 10 percent in the range 27-37 MeV.

Use data Thief to make your own version of Figure 6, with you simulation results overlayed, and legend includes reference.

The previous data measurements only seem high in the range 20-37 MeV (ref. File:Ignatyyuk U238 nxsetion upto150MeV.pdf page 5).

Also create Xmgrace version of U-238 X-sect with your simulation result and the red line average from above overlayed.

What is mistake for E=3 MeV U-238 simulation? Number was from wrong file, pilot error.

|

|

|

4.) Drill holes into the TGEM chamber to mount the HV boards

not done, starts working together as soon as the plates ready.

5.) Simulation Cross Section

New simulation for U-238 under new conditions. but still the simulation is running

I changed the N02SteppingVerbose in a way that can record all fission fragments properties for the 1st, second and third fission reaction for a certain incident neutron energy:

if(NumberOfFissionFragments>0 && fTrack->GetDefinition()->GetAtomicMass()<228 && fTrack->GetDefinition()->GetAtomicMass()>2 && fTrack->GetCurrentStepNumber()==1 && (fTrack->GetParentID()==1 || fTrack->GetParentID()==2 || fTrack->GetParentID()==3))

09/02/10

- RETGEM Preparation

TGEM plate is is prepared as the picture shows below, then covered with resistive paste.

|

|

|

- Sparking Test

A single TGEM plate was installed into the ionization chamber and a voltage was applied across the top and bottom of the plate. Sparks were observed when the voltage difference between the top and bottom of the resistive plate reached 2.8 kV. The sparks appeared to be localized to one of the holes. I will take the plate out and try to clean the hole further by filing away resistive paste around the hole. For comparison, the same foil didn't spark until a voltage difference of 7 kV was reached in air. According to Figure 14 in Media:Jinst8_02_p02012_THGEM_spark.pdf , a voltage difference of 1550 Volts was needed in the Double RTGEM configuration to achieve a gain less than 10^4. Our goal is a gain of 10^6 using 3 RTGEM plates. This suggests we should try to reach high voltage differences of at least 2 kV on each plate without sparking.

Sparking test had been done as the detector have air, the highest source voltage recorded was 7 kV. The detector filled with Ar-gas, the highest source voltage detected was 2.8 kV. There is a specific hole that the spark is on, then at around 5 kV it starts to spread around the hole.

An order of needle files will reach tomorrow, another sparking test will be done tomorrow after cleaning the holes and adding more paste.

Do not add more resistive paste yet.

Insert the density of copper and the density of the resistive paste here in the wiki.

09/09/10

- Densities

| Material Name | ED-7100 | Copper |

| Density(g/cm3) | 1.2 g/cm^3 (9.97lbs/gal) | 8.92 g/cm^3 |

- Sparking Test

Sparking test is repeated again after cleaning the hole, cleaning by the new set of files is not effective, the same observation seen again without any improvement from last time.

- Cleaning method

Using the chemicals for cleaning the small holes when the file size is not suitable is suggested by one of the companies.

email from MSCMetalworking.com - Robert <MSCMWtechteam@mscdirect.com> :

e have not heard of anyone making a file that small. Depending on how bad the burr is you might want to try this. Get a .019" DIA pin gage and some lapping compound and see if by spinning the pin in the hole with the compound that it will take care of the burr. Here are the MSC part numbers for the pin and compound. 78372166 [16] 05652581 [17]

- Ionization Simulation

A success in tracking an ionization and resultant electrons from the process is done using N03 edited to have an absorber of Ar-CO2 used mixture:

Region <DefaultRegionForTheWorld> -- appears in <World> world volume

Root logical volume(s) : World

Pointers : G4VUserRegionInformation[0], G4UserLimits[0], G4FastSimulationManager[0], G4UserSteppingAction[0]

Materials : Galactic ArCO2

Production cuts : gamma 1 mm e- 1 mm e+ 1 mm

========= Table of registered couples ==============================

Index : 0 used in the geometry : Yes recalculation needed : No

Material : Galactic

Range cuts : gamma 1 mm e- 1 mm e+ 1 mm

Energy thresholds : gamma 9.9e+02 eV e- 9.9e+02 eV e+ 9.9e+02 eV

Region(s) which use this couple :

DefaultRegionForTheWorld

Index : 1 used in the geometry : Yes recalculation needed : No

Material : ArCO2

Range cuts : gamma 1 mm e- 1 mm e+ 1 mm

Energy thresholds : gamma 9.9e+02 eV e- 9.9e+02 eV e+ 9.9e+02 eV

Region(s) which use this couple :

DefaultRegionForTheWorld

====================================================================

### Run 1 start.

Start Run processing.

---> Begin of event: 0

--------- Ranecu engine status ---------

Initial seed (index) = 0

Current couple of seeds = 814376083, 879723252

----------------------------------------

*********************************************************************************************************

* G4Track Information: Particle = N14[0.0], Track ID = 1, Parent ID = 0

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -3 cm 0 fm 0 fm 7 MeV 0 eV 0 fm 0 fm World initStep

1 -2.5 cm 0 fm 0 fm 7 MeV2.73e-15 eV 5 mm 5 mm World Transportation

2 -2.5 cm 0 fm 0 fm 6.96 MeV 39.8 keV 14.9 um 5.01 mm ArCO2 ionIoni

3 -2.5 cm -2.46 Ang-5.07e+04 fm 6.92 MeV 33.2 keV 14.7 um 5.03 mm ArCO2 ionIoni

4 -2.5 cm -2.87 Ang-5.84e+04 fm 6.92 MeV 5.5 keV 4.47 um 5.03 mm ArCO2 ionIoni

5 -2.5 cm -2.88 Ang-5.93e+04 fm 6.92 MeV 73.7 eV 43.2 nm 5.03 mm ArCO2 ionIoni

6 -2.49 cm -7.11 Ang -9.68 Ang 6.85 MeV 69.8 keV 23.1 um 5.06 mm ArCO2 ionIoni

7 -2.49 cm -7.16 Ang -1.06 nm 6.84 MeV 6.9 keV 2.9 um 5.06 mm ArCO2 ionIoni

8 -2.49 cm -1.19 nm -1.73 nm 6.78 MeV 58.9 keV 22.2 um 5.08 mm ArCO2 ionIoni

9 -2.49 cm -1.38 nm -2.58 nm 6.73 MeV 47.2 keV 20.5 um 5.1 mm ArCO2 ionIoni

10 -2.49 cm -1.82 nm -5.11 nm 6.66 MeV 69.5 keV 42.2 um 5.15 mm ArCO2 ionIoni

11 -2.48 cm -2.09 nm -5.86 nm 6.63 MeV 31.2 keV 16.2 um 5.16 mm ArCO2 ionIoni

12 -2.48 cm -2.41 nm -6.52 nm 6.6 MeV 25.1 keV 13.4 um 5.17 mm ArCO2 ionIoni

13 -2.48 cm -2.87 nm -8.21 nm 6.52 MeV 84.5 keV 40.2 um 5.21 mm ArCO2 ionIoni

14 -2.47 cm -3.24 nm -12.3 nm 6.32 MeV 195 keV 78.5 um 5.29 mm ArCO2 ionIoni

15 -2.43 cm -5.06 nm -32.1 nm 5.55 MeV 769 keV 382 um 5.68 mm ArCO2 ionIoni

16 -2.4 cm -6.78 nm -50.7 nm 4.67 MeV 886 keV 360 um 6.04 mm ArCO2 ionIoni

17 -2.36 cm -8.38 nm -68.2 nm 3.82 MeV 845 keV 337 um 6.37 mm ArCO2 ionIoni

18 -2.33 cm -9.89 nm -84.6 nm 3.02 MeV 797 keV 317 um 6.69 mm ArCO2 ionIoni

19 -2.3 cm -11.3 nm -100 nm 2.25 MeV 773 keV 299 um 6.99 mm ArCO2 ionIoni

20 -2.27 cm -12.7 nm -115 nm 1.55 MeV 703 keV 285 um 7.27 mm ArCO2 ionIoni

21 -2.25 cm -14 nm -129 nm 1.03 MeV 513 keV 272 um 7.54 mm ArCO2 ionIoni

22 -2.22 cm -15.2 nm -143 nm 619 keV 415 keV 262 um 7.81 mm ArCO2 ionIoni

23 -2.19 cm -16.4 nm -155 nm 349 keV 270 keV 250 um 8.06 mm ArCO2 ionIoni

24 -2.17 cm -17.5 nm -168 nm 117 keV 232 keV 235 um 8.29 mm ArCO2 ionIoni

25 -2.15 cm -18.5 nm -178 nm 0 eV 117 keV 193 um 8.48 mm ArCO2 ionIoni

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 13, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.48 cm -2.87 nm -8.21 nm 998 eV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.48 cm -1.27 um 1.81 um 0 eV 998 eV 57.4 um 57.4 um ArCO2 eIoni

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 12, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.48 cm -2.41 nm -6.52 nm 1 keV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.48 cm -2.23 um -1.32 um 0 eV 1 keV 57.8 um 57.8 um ArCO2 eIoni

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 11, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.48 cm -2.09 nm -5.86 nm 1.03 keV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.48 cm 1.19 um 568 nm 0 eV 1.03 keV 59.8 um 59.8 um ArCO2 eIoni

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 10, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.49 cm -1.82 nm -5.11 nm 1 keV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.48 cm 1.31 um -2.62 um 0 eV 1 keV 57.7 um 57.7 um ArCO2 eIoni

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 9, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.49 cm -1.38 nm -2.58 nm 993 eV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.49 cm 224 nm 3.5 um 0 eV 993 eV 57 um 57 um ArCO2 eIoni

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 8, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.49 cm -1.19 nm -1.73 nm 1.01 keV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.49 cm -2.39 um 2.17 um 0 eV 1.01 keV 58.5 um 58.5 um ArCO2 eIoni

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 7, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.49 cm -7.16 Ang -1.06 nm 999 eV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.49 cm 3.77 um -385 nm 0 eV 999 eV 57.5 um 57.5 um ArCO2 eIoni

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 6, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.49 cm -7.11 Ang -9.68 Ang 1.01 keV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.49 cm 4.91 um -7.92 um 658 eV 356 eV 19.7 um 19.7 um ArCO2 msc

2 -2.49 cm 12.8 um -6.9 um 0 eV 658 eV 34.6 um 54.3 um ArCO2 eIoni

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 5, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.5 cm -2.88 Ang-5.93e+04 fm 1.03 keV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.5 cm -9.66 um -402 nm 834 eV 193 eV 19.8 um 19.8 um ArCO2 msc

2 -2.5 cm -9.32 um 10 um 584 eV 250 eV 19.8 um 39.7 um ArCO2 msc

3 -2.5 cm -6.96 um 7.34 um 0 eV 584 eV 19.8 um 59.5 um ArCO2 msc

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 4, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.5 cm -2.87 Ang-5.84e+04 fm 992 eV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.5 cm 11.2 um 4.42 um 992 eV 0 eV 19.5 um 19.5 um ArCO2 msc

2 -2.5 cm 24.4 um 9.57 um 965 eV 26.6 eV 19.5 um 38.9 um ArCO2 msc

3 -2.5 cm 28.7 um 5.64 um 846 eV 119 eV 19.5 um 58.4 um ArCO2 msc

4 -2.5 cm 34.4 um 2.56 um 436 eV 410 eV 19.5 um 77.8 um ArCO2 msc

5 -2.5 cm 35.8 um -153 nm 5.97 eV 430 eV 19.5 um 97.3 um ArCO2 msc

6 -2.5 cm 36.2 um -774 nm 0 eV 5.97 eV 2.26 um 99.5 um ArCO2 eIoni

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 3, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.5 cm -2.46 Ang-5.07e+04 fm 1.08 keV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.5 cm -8.67 um 7.15 um 630 eV 445 eV 20.5 um 20.5 um ArCO2 msc

2 -2.5 cm -9.31 um 11.5 um 0 eV 630 eV 20.5 um 41.1 um ArCO2 msc

*********************************************************************************************************

* G4Track Information: Particle = e-, Track ID = 2, Parent ID = 1

*********************************************************************************************************

Step# X Y Z KineE dEStep StepLeng TrakLeng Volume Process

0 -2.5 cm 0 fm 0 fm 1.04 keV 0 eV 0 fm 0 fm ArCO2 initStep

1 -2.5 cm 2.01 um 10.8 um 1.02 keV 14.4 eV 20 um 20 um ArCO2 msc

2 -2.5 cm -9.15 um 16.7 um 760 eV 262 eV 20 um 40 um ArCO2 msc

3 -2.5 cm -22.9 um 18.9 um 380 eV 380 eV 20 um 60 um ArCO2 msc

4 -2.5 cm -25.3 um 15.8 um 0 eV 380 eV 20 um 79.9 um ArCO2 msc

---> End of event: 0

Absorber: total energy: 7 MeV total track length: 4.2 mm

Gap: total energy: 0 eV total track length: 0 fm

Run terminated.

Run Summary

Number of events processed : 1

User=0s Real=0.16s Sys=0.01s

--------------------End of Run------------------------------

mean Energy in Absorber : 7 MeV +- 0 eV

mean Energy in Gap : 0 eV +- 0 eV

mean trackLength in Absorber : 4.2 mm +- 6.5e+03 fm

mean trackLength in Gap : 0 fm +- 0 fm

Notes:

- It is not clear yet if there are other particles produced through the ion track. "G4ionIonisation" is the only process used.

- The absorber thickness will determine the ion maximum energy and the number of tracked electrons. so the fission fragments won't all share in the ionization but the ones have the appropriate energy (and mass).

09/14/10

defaultCutValue

Set defaultCutValue=1.0*mm in example N02 to see if you can get ionized electron tracking.

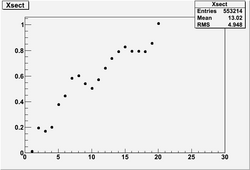

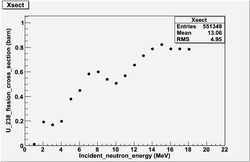

- U-fx-section Simulation

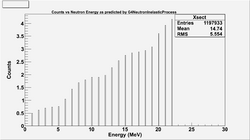

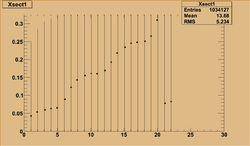

The figures show the U-fxsection in case of counting the fragments from 1st fission reaction only and counting the fragments from fission reactions that follow the the 1st one.

| 1st_2nd_3rd Fission | 1st_Fission |

|

|

Notes: the first figure shows an increase in the value of f-xsection when the incident neutron energy is 10 MeV or more, also the f-xsection is increasing when the energy is 20 MeV. So the first figure is closer to the experimental fission cross given by ENDF [[18]].

Overlay the above results onto the ENDF plot.

- TGEM Detector Plates

10X10 holes 0.5mm diameter and 1.3mm center to center distance are going to be ready tomorrow. Sparking test results are going to be ready by the next meeting.

10/18/10

Haithem's daily log report: oles are dre

10/19/10

- New TGEM (HTTGEM_1)

Three HTTGEM_1 foils were manufactured and tested up to 3 kV in air. The same foils would hold 2.2-2.3 kV when immersed ina 90/10 ArCO2 gas mixture.

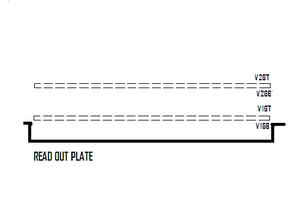

- The design of HTTGEM_1

Each HTGEM_1 is constructed using 0.5 mm thick copper clad FR4 plate that are 12 x 12 cm in size. The copper layer is 17 um thick. The copper is etched until a 2 mm thick border remains around the plate which will be used to apply a voltage between the top and bottom of the plate. The exposes FR4 is coated with the resistive paste ED-7100. Holes of diameter 0.5 mm (0.02") are drilled in a pattern as in the figure below. A rim of width 0.15 mm is made around each hole to separate the hole from surrounding resistive paste. The hole pitch is 0.8 mm.

10/20/10

No reported work done (please look at the experiment timetable) [19]

10/21/10

No reported work done (please look at the experiment timetable) [20]

10/22/10

No reported work done (please look at the experiment timetable) [21]

10/24/10

- HTTHGEM sparking test

Previously mentioned that HTTHGEM foil individually passed the sparking test up to 3 kV in air, as soon as they are connected by the HV-circuit, the electric field produced by each foil has an effect on the other foil, the effect appears as sparking. Two of HTTHGEM were recently tested in air when a separation distance was 9mm, sparking around the holes started when the source voltage was about 5 kV (about 1.3 kV on each foil).

10/27/10

- Sparking test for two-HTTHGEM in air

Two HTTHGEM foils placed in TGEM chamber, they were shorted to HV-power supply simultaneously, the foils passed the sparking test in air up to 3 kV with a separation distance between them of magnitude of 2 mm. The foils were shorted according to the table (the bottom foil placed in the chamber is HTTHGEM_1) :

| bottom | top | |

| HTTHGEM_1 voltage | high | low |

| HTTHGEM_2 voltage | low | high |

If I understand the above configuration, then I would not expect electrons to pass through HTTHGEM 1 and head towards HTTHGEM 2. It would minimize sparking because there would be no potential difference between the top of HTTHGEM2 and the bottom of HTTHGEM1. Please construct the configuration I requested; a HV connector on each THGEM card. The next configuration will be to create a potential difference (100 Volts) between the bottom of HTTHGEM 1 and the top of HTTHGEM 2.

- Sparking test for two-HTTHGEM in Ar/CO2

| Distance between the foils (mm) | maximum voltage before spaking (kV) | notes |

| 2 | 1 | more than 1 kV sparking started from the edges then the holes |

| 5 | not complete, the foils start to spark as the voltage is 1 kV, they should be cleaned |

- Original HV-circuit [22]

The link is for the original HV-circuit, there is a capacitor connected before the wire goes to the bottom of the first THGEM, I wonder if this capacitor is a job related to collecting charge. I will try to connect one before the wire goes to HTTHGEM to check if it will give any changes.

10/28/10

- Beak board

The new break board is ready for use.

10/29/10

- Sparking Test for two HTTHGEM in air

Two of HTTHGEM have been shorted to two different power supply as represented in the table:

| bottom | top | |

| HTTHGEM_1 voltage | ground | high |

| HTTHGEM_2 voltage | ground | high |

The results are summarized by the table

| HTTHGEM_1 | HTTHGEM_2 | observation | |

| voltage (kV) | 1 | 1 | no sparking |

| voltage (kV) | 1.5 | 2 | sparking and burning, HTTHGEM_2 was on 2 kV, gradually HTTHGEM_2 voltage increased until 1.5 kV |

|

|

Cleaning and reapplied the paste on the damaged foil to repeat the experiment under Ar/CO2.

10/30/10

The above damage is impressive. Why are sparks absent when the card is at 2 kV and alone but there is sparking if it is within a second card. What was the separation distance between the to cards when the sparking happened.

For the above table results the separation distance is 5 cm.

- Reasons for sparking

- Current loops in the HTTHGEM foil.

- This situation reminds me a lot with mutual inductance, but instead of the magnetic field, it is for electric field, since the current existance is an evidence for a change (only electric field lines here), as I am changing the voltage, electric field lines density changes, a force is produced inside the HTTHGEM_2 to resists the change, but what is really impressive if this is right, the damage should in the foil where the forced is produced not the other foil!!