Difference between revisions of "Neutron TGEM Detector Abdel"

| Line 19: | Line 19: | ||

The TGEM PCboard would have a surface area of 10 cm x 10 cm. | The TGEM PCboard would have a surface area of 10 cm x 10 cm. | ||

| + | |||

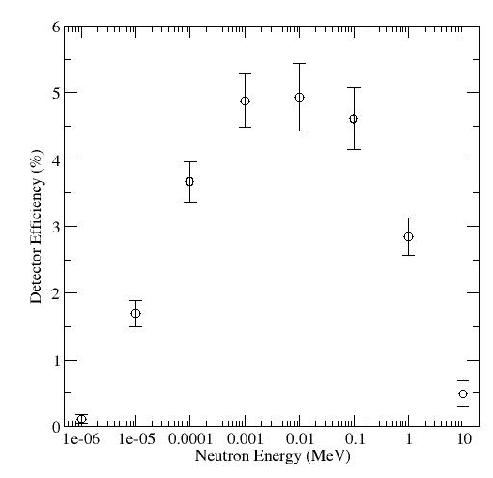

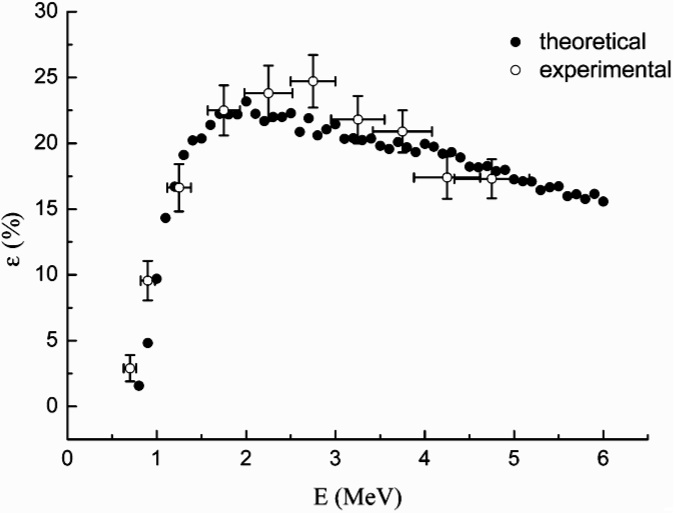

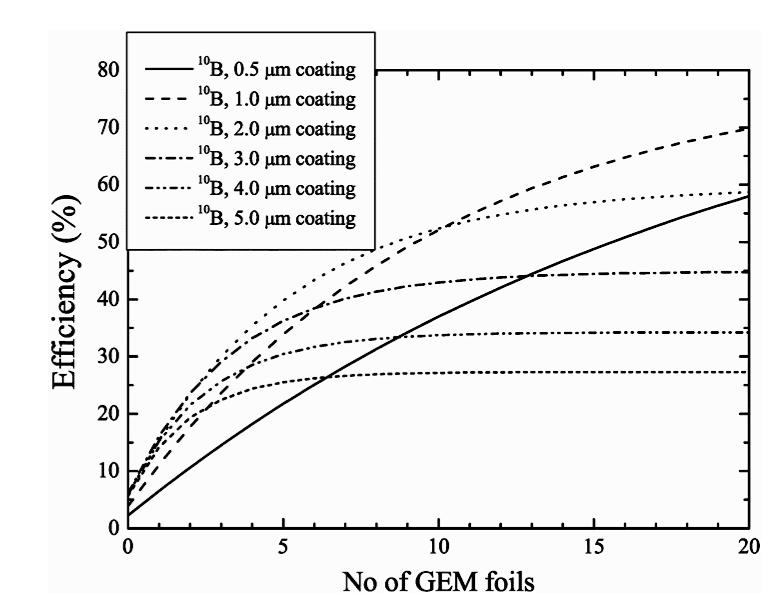

| + | 3.) Current neutron efficiency plots for several detector | ||

| + | |||

| + | [[Image:NeutronDetectionEfficiency-vs-Energy_He3_Tube_PND_INL.jpg]] | ||

| + | |||

| + | [[Image:NeutronDetectionEfficiency-vs-Energy_Ne-213_BaF.tiff]] | ||

| + | |||

| + | [[Image:NeutronDetectionEfficiency-vs-Energy_BC-408_Scintillator.jpg]] | ||

| + | |||

| + | [[Image:NeutronDetectionEfficiency-vs-Energy_GEM_BoronCoatedFoil_Neutron_Efficiency.jpg]] | ||

Revision as of 18:25, 23 January 2009

Haithem's logbook for developing neutron sensitive TGEM detector

1/23/09

1.) Search the web for patent which coats GEM detector with neutron sensitive materials. I think it is for Thermal neutrons.

A boron coated GEM foil is being made by the company below http://n-cdt.com/

Another method uses BF3.

We are interested in a fissionable material coated onto the copper foils that is thin enough to allow the fission fragments to escape the foil and ionize the gas in the detector.

2.) Search for companies which use either sputtering or coating technology to apply the above material to caopper PCboards with hole int them such that the material does not fill up the hole. Hole diameter = ?

The material sputter onto the copper would have thickness on the order of Angstroms.

The TGEM PCboard would have a surface area of 10 cm x 10 cm.

3.) Current neutron efficiency plots for several detector