Difference between revisions of "CLAS12 R1"

| Line 59: | Line 59: | ||

[[File:BasementRenovationDrawing_6-28-10.pdf]] Changes to machine shop door | [[File:BasementRenovationDrawing_6-28-10.pdf]] Changes to machine shop door | ||

| + | |||

| + | [File:BasementRenovationDrawing_7-26-10.pdf]] Maybe the Final design with 8' hallways and 8' doors to the clean room | ||

Revision as of 23:32, 26 July 2010

Time line

Time needed to train lead stringer at JLab = 4-6 weeks?

| Start Date | End Date | Description |

| 5/17/10 | 9/30/10 | Sign MOU, Contract |

| 8/3/2010 | 8/3/2010 | Readiness Review |

| 9/1/10 | 10/29/10 | Hire and train R1 Lead Stringer |

| 10/1/10 | 2/28/11 | Hire and train 2 R1 stringers |

| 11/16/09 | 11/30/10 | Build R1 Cleanroom |

| 11/5/2010 | 11/12/2011 | Ship 1st R1 Box From JLab to ISU |

| 12/17/2010 | 2/28/2011 | String First R1 Chambers |

| 2/21/2011 | 3/31/2011 | Ship remaining R1 Boxes From JLab to ISU |

| 7/13/12 | Complete 6th R1 chamber | |

| 4/5/13 | 9/30/13 | Ship chambers, fixtures, platforms and crane to JLab |

4 ingredients to contract

1.) MOU: Memorandum of Understanding,

2.) SOW: Statement of Work

3.) Detailed Schedule

4.) Sole Source Justification

5.) Contact person: Pre Award Dave Harris? Approve Terms and conditions

University gets a Purchase Req: covers SOW, Terms & Condition, & Schedule.

We respond with proposal containing exceptions and work plan. 1 team of 2 stringers can do a wire in 6 minutes. Stringers spend 1/2 of their time stringing the rest of time preparing , Q&A, ... JLab expects a crew of 5 people. If we think we can't make the schedule we need to ask for more people. Stringers hourly rate ($30-$35/hr with overhead and benefits). Lead stringer is +$5/hr more.

Then they respond with contract.

"Cost Reimbursable" contract, University not liable if we go over budget

Can we survey to 50 microns? No. 200 microns.

ISU Clean Room Facility

File:BasementRenovationDrawing 6-16-10.pdf

File:BasementRenovationDrawing 6-28-10.pdf Changes to machine shop door

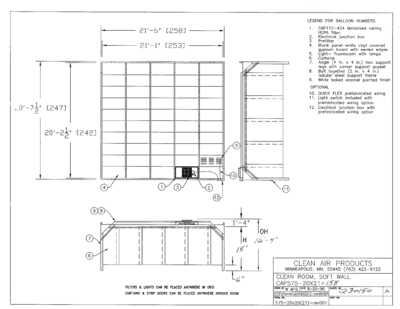

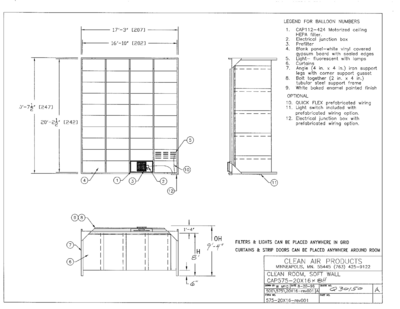

[File:BasementRenovationDrawing_7-26-10.pdf]] Maybe the Final design with 8' hallways and 8' doors to the clean room

Pictures of the ISU Squash Court

6/18/09

The clean room needs space for instrumenting. The DC will be layed horizontal so PC cards can be mounted and tested.

6/24/10

11' = hook height in stringing clean room

There are 2 stringing strong back and 6 shipping strong backs. They bolt on separate sides of the chambers.

Idea: Instrument the chamber on the ledge above the squash court. Put a lift on the pole which we can use to turn the DC from its standing (stringing) position to its horizontal (instrumentation) position then "swing" it over onto the squash court ledge.

No Halogen lighting.

Think about air conditioning. People are space heaters.

Have shoes specific for clean room instead of booties.

Clean room floor plane for Basement and Airport

Here is a preliminary floor plan for the Updated clean room in the ISU Basement

File:Clean Room Squash Court.eps

replace the above with a PNG or JPG file so we can see it in the wiki

Pros and Cons of Locations

- Physics Basement

- Pros

1.) similar size to ODU just 5 feet shorter.

20x39x15' -vs- 20x40x20;

2.) more quality control: 4 Physics professors more likely to look in on construction in between classes

3.)established record of temperature control

4.) closer to other facilities; machine shops, electronics, ...

- Cons

1.) must move detector standing up to get through 6' hallway

2.) more heavy lifting when bringing in and out of basement (this is only 2 day out of the months involved in construction)

- Airport

- Pros

1.) Plenty of Room

- Cons

1.)adds > $10k to cost of clean room

2.) far away from professors eyes (could be a pro)

Construction Quotes

We are currently waiting on quotes from the following companies on the construction of the Clean Room (both specs) at ISU. They are Modular Clean Rooms and Clean Air Products. Once quotes are received, pdf's of the quotes will be uploaded online.

2010 July 14

Quote from Clean Air Products for the ISU Basement:

File:Clean Air Quote No Filters.pdf

Dimensions of door from loading dock to clean room 65" wide 90" high

The doors into and out of the different areas will be 9'8" high in order to help facilitate the transport of equipment into and out of the different areas of the clean room.

The desks in the clean room will act as a table top area to place tools and other equipment currently in use during the construction of the wire chambers. Also, they will serve as a place to perform any calculations or other miscellaneous work that may come up while construction is ongoing.

The cabinets on the other side of the room will be a permanent storage area for all tools and equipment not currently in use at the two work stations.

The path in between the workstations and the cabinets will be kept clear of all obstructions in order facilitate the movement of equipment into and out of the room as needed.

The two workstations will be where the wire chambers are constructed. The workstations will have a standing/sitting apparatus built around them in order to help those who are stringing the wire chambers to have better access to the chambers from above. Schematics for these will be uploaded as they are designed.

The heavy equipment storage area will be where all the heavier equipment (i.e. dollies, fabrication materials, etc...) that will not fit, or does not need to be stored in the individual work station cabinets will be kept.

The HEPA filters will cover roughly ~10-12% of the ceiling in order to maintain a Class 10,000 environment. The filters will move approximately 35-40 air volumes per hour.

Overhead lighting will be suspended from the frame in order to provide sufficient lighting for the room occupants to work within.

HEPA Filters

Due to the cost of HEPA filters, a multistage filtration system will be used with the HEPA filters at the end of the system in order to insure the longevity of the HEPA filters.

More information will be forthcoming on this in the future.

ODU's Clean Room

ODU's current clean room size:

20 ' high 20 ' Width 40 ' Length

CLAS 10,00 clean rooms

Environmental control needed

Temperature control constraint is

The wire tension can fluctuate no more than 5% from the mean wire tension specification.

This means that the temperature should be controlled to within +/- 2 Degrees Ferenheit

Humidity control: 55 % or less

File:KashyHallBTempReport 2-09.docFile:KashyHallBTempReport 2-09.pdf

Cleaning Procedures

R1 Construction preparations

Wire Tension

A Helmholtz coil is used to test the wire tension

Below is a write up from BaBar

File:Device2MeasureWireTension Covery BaBarReportTNDC-96-39 1996.pdf

File:ODU WireTensionMeasurements 10-2009.pdf

An excel spreadsheet to calculate fields for such coils is given at

http://clasweb.jlab.org/drawings/CLAS12/DRIFT_CHAMBERS/Helmholz_calculator.xls

The formula is from Physics 10X but more importantly it contains wire parameters useful for the calculation

Discussion items

1.) Budget

- JLab to ISU travel for JLab personnel to inspect operations

- shipping container for R1 chambers

2.) Clean room

cost =

assume we copy the ODU clean room

Using IAC conference room space, need to remove carpet and paint floor.

3.) hiring timeline

9/08 NSF proposal submission

4.) stringing platform and DC stringing support arm

5.) Manpower

6.) MOU to support post doc request or faculty release time

7.) Stringing equipment

a.) crimping tool

b.) glue

c.) wire or feedthroughs?

d.) wire tension measurement (PC, Magnets, associated electronics

A few pictures ff the R1 fullo size proto type from my JLab visit on 9/16/07. It is about 6 feet tall. CLAS12_R1_Prototype_9-16-07

The air actuated crimping tool:

CLAS12_R1_Progress_Reports

Vendors

http://www.cleanairproducts.com/

References

Stringing Manual

Media:R1_CLAS12_StringingManual_2008.doc Media:R1_CLAS12_StringingManual_2008.pdf

JLab job posting for lead stringer

CLAS Wire Chamber Technician

Requisition Number 10534 Job Category Technician/Drafter Percentage of Travel No Travel Job Responsibilities (TERM POSITION ENDING TWO YEARS FROM HIRE DATE)

DATE POSTED: FEBRUARY 11, 2010

SALARY RANGE: $45,500 - $61,900 (TD II)

DUTIES: Technician will be responsible for the fabrication of very large and very precise particle detection units called "wire chambers" in support of the CLAS 12 GEV project. These "wire chambers" will be built in a clean room by teams. Incumbent is expected to lead these fabrication teams. Specifically, individual will be responsible for leading a team in building these detectors and maintaining strict quality controls. Will be required to learn all aspects of detector fabrication, stringing and testing. Will fabricate and string the detectors maintaining high precision and quality. Will receive, clean and inspect parts for compliance with technical specifications.

Experience/Education Required MINIMUM QUALIFICATIONS:

Associates Degree plus 3 years of applicable experience or equivalent combination of education and relevant experience. Knowledge of basic electricity and/or electronics required. Knowledge and experience in the proper use of hand and power tools as well as ability to follow written procedures in operating and technical manuals also required. Basic computer skills such as Excel and/or CAD experience is a plus. Ability to work in a team environment. A background in quality control as well as experience supervising and motivating others in a team setting preferred.

Physical Requirements: - Pass all medical requirements for the following qualifications: Rad Worker, ODH, Crane Operator, Forklift Operator, Aerial Platform Operator, etc. - Cannot have a fear of heights or confined spaces. - Must be able to climb stairs, ladders, vertical escape ladders and work in close quarters with others. - Steady hands and eyes for delicate close-up work.