Difference between revisions of "IAC LeadFlourideCherenkovCrystalTests 5-09"

(→Day 1) |

|||

| Line 53: | Line 53: | ||

Beam setup & 2-3 hours | Beam setup & 2-3 hours | ||

| + | |||

| + | 11:25 AM - | ||

| + | |||

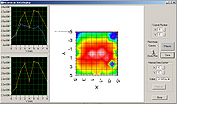

| + | [[Image:Beamscan9.6x9.6.5.09.JPG | 200 px]] | ||

1) Shoot glass plate at 30cm from exit port | 1) Shoot glass plate at 30cm from exit port | ||

Revision as of 17:25, 11 May 2009

http://clasweb.jlab.org/wiki/index.php/Hall_A_IAC_Tests

Previous Tests: IAC_LeadFlourideCherenkovCrystalTests

Run Plan

Summary

| Task | Time Budget |

| Beam setup | 0.5 days |

| Testing 20 new blocks | 2.5 days |

| Silicon test | 1.0 day |

| Bleaching/Re-irradiation test | 0.5-1 day |

| Testing old blocks | 12 blocks/day |

- Accelerator Settings

| beam energy | 20 MeV |

| Rep Rate: | 30 Hz |

| I_peak: | 60 mA/pulse |

| pulse width: | 0.1 s (100 ns) |

Day 0

Experiment Set-up Tasks:

1) Translator table -positioned in front of 0 degree exit port and manual operation (50,000/inch).

2) Faraday Cup - positioned at z = 30 cm, clipped (alligator to BNC & grounded), connected to cable C6, terminated into Channel 1 on the scope.

3) Green pick-up loop -Sits freely atop poly blocks in front of exit window with poly spacers between loop and exit window to prevent grounding, connected to cable C7, terminated into channel 3 (?) on scope (re-check this on morning of Day 1).

4) Fluke multimeter & camera set-up for real-time temperature monitoring - camera positioned and focused, connected via cable C5 to DAQ monitor.

5) Glass plate -unable to locate small size plate on Day 0, will look again morning of Day 1. Beam spot size measurement not crucial given properly operating beam scan software.

6) Beam scan -Brian is troubleshooting this software, will show Adrianne how to use the morning of Day 1.

Day 1

Beam setup & 2-3 hours

11:25 AM -

1) Shoot glass plate at 30cm from exit port

2) Temperature test with 1 old block

3) Irradiation batch 1:3 new blocks + 1 old ``reference block

4) Irradiation batch 2:4 new blocks

Bleaching of batch 2: 29 hours

5) Irradiation batch 3:4 new blocks

Day 2

Irradiation batch \#4:&4 new blocks\\ Irradiation batch \#5:&4 new blocks\\ Irradiation {\bf batch \#2}:&4 new blocks\\ Bleaching of batch \#2:&24 hours\\

Day 3

- Accelerator Settings

| beam energy | 20 MeV |

| Rep Rate: | 30 Hz |

| I_peak: | 60 mA/pulse |

| pulse width: | 0.1 s (100 ns) |

1.) Irradiate Silicon detector for 2-3 hours

Minimum ionizing particles deposit 0.19 MeV of energy /,J). If we want to irradiate particles/s, that makes J/s. Taking into account the strip size and the heat capacity of Si (19.8 J/mol/K), this makes a temperature variation of 0.045 K/min (negligeable).

2.) Irradiation PB crystal batch \#2 then Bleaching of batch #2 for 38 hours

Day 4

Irradiation batch \#6:&4 new blocks\\ Irradiation batch \#7:&4 new blocks\\ Irradiation batch \#8:&4 new blocks\\

Day 5

Irradiation {\bf batch \#2}\\ \multicolumn{2}{l}{Silicon test}\\ Day 6 -- Bleaching of batch \#2:&24h\\