Difference between revisions of "TF DOE EPSCOR 2018"

| (11 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Forest_Proposals]] | [[Forest_Proposals]] | ||

| − | + | =Neutron Capture on Chlorine= | |

| − | BNL report from 4/23/18 on Phenomena Important in Modeling and Simulation of Molten Salt Reactors | + | NEUTRON CROSS SECTIONS OF NATURAL CHLORINE |

| + | |||

| + | Prepared by M. L Kalos and J. H. Ray | ||

| + | |||

| + | 30 September 1963 | ||

| + | |||

| + | [[Media:KalosRay_1963.pdf]] | ||

| + | |||

| + | =BNL 2018 Report= | ||

| + | |||

| + | From a BNL report from 4/23/18 on Phenomena Important in Modeling and Simulation of Molten Salt Reactors | ||

[[Media:BNL_Report_4_23_2018.pdf]] | [[Media:BNL_Report_4_23_2018.pdf]] | ||

| + | =Neutron flux from various reactor types= | ||

| + | |||

| + | FHR: Nicholas R. Brown et al., "Preconceptual Design of a Fluoride High Temperature Salt-Cooled Engineering Demonstration Reactor: Core Design and Safety Analysis." Annals of Nuclear Energy 103, pp 49-59, 2017. | ||

| + | |||

| + | MCFR: M. Taube and J. Ligou. "Molten Plutonium Chlorides Fast Breeder Reactor Cooled by Molten Uranium Chloride," Annals of Nuclear Science and Engineering, 1.4, pp 277-281, 1974 | ||

| + | |||

| + | IS_MSR: N.R.Brown et al., “Sustainable Thorium Nuclear Fuel Cycles: A Comparison of Intermediate and Fast Neutron Spectrum Systems,” Nuclear Engineering and Design, 289, pp 252-265, 2015. | ||

| + | |||

| + | LWR: generic light water reactor | ||

| + | SFR: Sodium cooled fast reactor | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | [[File:NeutronFluxFromVariousFreactorTypes_BNL-4-23-2018.png | 400 px]] | ||

| + | |||

| + | |||

| + | ==Quotes from the above report== | ||

| + | " A major recommendation of this study is that modeling and simulation of MSRs will require development of computational tool(s) capable of tracking chemical inventories of | ||

| + | constituents throughout the primary loop of the reactor facility. Such a tool is not a vital part of water reactor safety analysis since the coolant is a single component (either light or heavy water) with dilute concentrations of other species such as boron or lithium. Thus, an inventory control and evaluation tool is a unique feature necessary for liquid-fuel reactors. (The issue may be relevant to solid-fuel MSRs but was not a consideration in this pre-PIRT.) A comprehensive evaluation of fuel salt composition will likely require the modeling of salt chemistry, thermodynamics, mass transport, and addition and removal of chemical species. Fission and transmutation products will be generated in the salt and will form a variety of chemical species. The phase behavior of these species is complex, and depends on the specific design, particular fuel salt, and plant operation. " | ||

| + | |||

| + | "For fast spectrum chloride salts, there is a need for high flux radiation stability tests to determine if radiolysis effects are significant and to determine the extent and distribution of fission gas products. The radiolysis of the salts could affect the composition of the salts and lead to formation of corrosive gaseous products such as chlorine gas. The rate of radiolysis and recombination is currently not known and needs experimental evaluation." | ||

| + | |||

| + | "Molten fuel salt reactors would have significantly different neutronic, thermal-fluid and chemical behavior than existing reactors and may require a wide range of fundamental experiments to characterize their performance and safety. To date there have only been two domestic MSR test reactors, the Molten Salt Reactor Experiment (MSRE) [5-7] and the Aircraft Reactor Experiments (ARE) [5-8]. Both of these experiments used the fuel dissolved in the heat transfer salt. There has also been a number of separate effects experiments focused on understanding fundamental issues mainly focused on fluoride salts and to a much lesser extent chloride salts. The majority of these were conducted at Oak Ridge National Laboratory (ORNL) during the period of MSRE operation and are fairly well documented. Recently, there have been a handful of other separate effects experiments performed at U.S. national laboratories and abroad at other laboratories and universities. There remain several areas that need further investigation and confirmation in order to have a fundamental grasp of the thermal-hydraulic and safety performance of an MSR. New flow loops and integral test facilities utilizing molten salts will likely be necessary to develop models and correlations, and to assess code performance." | ||

| + | |||

| + | |||

| + | =RFP topics of interest= | ||

| + | |||

| + | For Nuclear Energy | ||

| + | |||

| + | Advanced Reactor Materials | ||

| + | |||

| + | High-temperature, radiation damage and corrosion-resistant materials for use in molten | ||

| + | salt systems. Materials that employ microstructure features to minimize neutron induced | ||

| + | loss of creep ductility in nickel-based alloys are especially desirable. Materials that | ||

| + | maintain desirable performance attributes at temperatures above 750 °C and can be | ||

| + | readily formed and joined are especially desirable. | ||

| + | Functional materials for valves, filters, control elements and drive mechanisms, gaskets, | ||

| + | impulse lines, bellows, and optical windows for molten salts. | ||

| + | |||

| + | |||

| + | Molten Salt Chemistry | ||

| + | |||

| + | An area of specific interest is molten salt chemistry, including (i) low-uncertainty molten | ||

| + | salt thermochemical and thermophysical properties for advanced nuclear systems, (ii) | ||

| + | practical techniques for implementing chemical control at MSRs, (iii) phase equilibria | ||

| + | and diagram data for molten salt bearing actinides and fission products, and (iv) fuel-salt | ||

| + | iodine removal techniques to minimize potential accident source term. | ||

| + | Instrumentation and techniques to rapidly and inexpensively assess the trace impurity | ||

| + | levels of newly received salts. | ||

| + | Low-cost, large-scale chlorine isotope separation techniques. | ||

| + | High thermal neutron cross section lanthanide element separation techniques from fuel | ||

| + | salt without prior actinide removal. | ||

| + | Techniques to process used fuel salts into stable waste forms. | ||

| + | Nuclear Data | ||

| + | Areas of interest include improving nuclear data for actinides and chlorine, including | ||

| + | neutron cross section refinement and covariance data for advanced nuclear fuels and | ||

| + | reactors. | ||

| + | |||

| + | Advanced Manufacturing | ||

| + | Techniques to apply high-quality, corrosion resistant layers/coatings (carbides, nitrides, | ||

| + | phosphides, refractory or noble metals, etc.) to high-temperature structural alloys for | ||

| + | molten salt reactors. Techniques suitable for long heat exchanger tubes and complex | ||

| + | geometries are especially desirable. Suitability for deployment in a high neutron flux | ||

| + | environment is also desired. | ||

| + | Tooling and techniques to support rapid replacement of used components to minimize | ||

| + | outage intervals. | ||

| + | Instrumentation | ||

| + | Low uncertainty heat balance instruments and measurement techniques (mass flow and | ||

| + | temperature difference) for utility scale molten salt coolant lines. | ||

| + | Rapid quantification instrumentation and techniques for residual fissile materials on used | ||

| + | components and filters being removed from the reactor containment. | ||

| + | Plant instrumentation to assess the composition (corrosion products, actinide isotopes, | ||

| + | tritium, oxygen) of small, periodically withdrawn, highly radioactive fuel salt samples. | ||

| + | Techniques and tooling to support remote replacement or recalibration of sensors within a | ||

| + | high-radiation containment. | ||

[[Forest_Proposals]] | [[Forest_Proposals]] | ||

Latest revision as of 17:15, 10 December 2018

Neutron Capture on Chlorine

NEUTRON CROSS SECTIONS OF NATURAL CHLORINE

Prepared by M. L Kalos and J. H. Ray

30 September 1963

BNL 2018 Report

From a BNL report from 4/23/18 on Phenomena Important in Modeling and Simulation of Molten Salt Reactors

Media:BNL_Report_4_23_2018.pdf

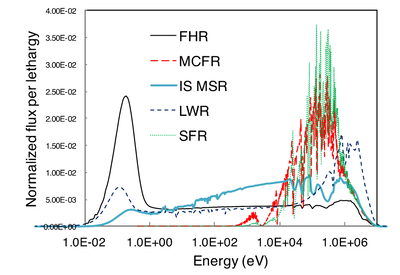

Neutron flux from various reactor types

FHR: Nicholas R. Brown et al., "Preconceptual Design of a Fluoride High Temperature Salt-Cooled Engineering Demonstration Reactor: Core Design and Safety Analysis." Annals of Nuclear Energy 103, pp 49-59, 2017.

MCFR: M. Taube and J. Ligou. "Molten Plutonium Chlorides Fast Breeder Reactor Cooled by Molten Uranium Chloride," Annals of Nuclear Science and Engineering, 1.4, pp 277-281, 1974

IS_MSR: N.R.Brown et al., “Sustainable Thorium Nuclear Fuel Cycles: A Comparison of Intermediate and Fast Neutron Spectrum Systems,” Nuclear Engineering and Design, 289, pp 252-265, 2015.

LWR: generic light water reactor SFR: Sodium cooled fast reactor

Quotes from the above report

" A major recommendation of this study is that modeling and simulation of MSRs will require development of computational tool(s) capable of tracking chemical inventories of constituents throughout the primary loop of the reactor facility. Such a tool is not a vital part of water reactor safety analysis since the coolant is a single component (either light or heavy water) with dilute concentrations of other species such as boron or lithium. Thus, an inventory control and evaluation tool is a unique feature necessary for liquid-fuel reactors. (The issue may be relevant to solid-fuel MSRs but was not a consideration in this pre-PIRT.) A comprehensive evaluation of fuel salt composition will likely require the modeling of salt chemistry, thermodynamics, mass transport, and addition and removal of chemical species. Fission and transmutation products will be generated in the salt and will form a variety of chemical species. The phase behavior of these species is complex, and depends on the specific design, particular fuel salt, and plant operation. "

"For fast spectrum chloride salts, there is a need for high flux radiation stability tests to determine if radiolysis effects are significant and to determine the extent and distribution of fission gas products. The radiolysis of the salts could affect the composition of the salts and lead to formation of corrosive gaseous products such as chlorine gas. The rate of radiolysis and recombination is currently not known and needs experimental evaluation."

"Molten fuel salt reactors would have significantly different neutronic, thermal-fluid and chemical behavior than existing reactors and may require a wide range of fundamental experiments to characterize their performance and safety. To date there have only been two domestic MSR test reactors, the Molten Salt Reactor Experiment (MSRE) [5-7] and the Aircraft Reactor Experiments (ARE) [5-8]. Both of these experiments used the fuel dissolved in the heat transfer salt. There has also been a number of separate effects experiments focused on understanding fundamental issues mainly focused on fluoride salts and to a much lesser extent chloride salts. The majority of these were conducted at Oak Ridge National Laboratory (ORNL) during the period of MSRE operation and are fairly well documented. Recently, there have been a handful of other separate effects experiments performed at U.S. national laboratories and abroad at other laboratories and universities. There remain several areas that need further investigation and confirmation in order to have a fundamental grasp of the thermal-hydraulic and safety performance of an MSR. New flow loops and integral test facilities utilizing molten salts will likely be necessary to develop models and correlations, and to assess code performance."

RFP topics of interest

For Nuclear Energy

Advanced Reactor Materials

High-temperature, radiation damage and corrosion-resistant materials for use in molten salt systems. Materials that employ microstructure features to minimize neutron induced loss of creep ductility in nickel-based alloys are especially desirable. Materials that maintain desirable performance attributes at temperatures above 750 °C and can be readily formed and joined are especially desirable. Functional materials for valves, filters, control elements and drive mechanisms, gaskets, impulse lines, bellows, and optical windows for molten salts.

Molten Salt Chemistry

An area of specific interest is molten salt chemistry, including (i) low-uncertainty molten salt thermochemical and thermophysical properties for advanced nuclear systems, (ii) practical techniques for implementing chemical control at MSRs, (iii) phase equilibria and diagram data for molten salt bearing actinides and fission products, and (iv) fuel-salt iodine removal techniques to minimize potential accident source term. Instrumentation and techniques to rapidly and inexpensively assess the trace impurity levels of newly received salts. Low-cost, large-scale chlorine isotope separation techniques. High thermal neutron cross section lanthanide element separation techniques from fuel salt without prior actinide removal. Techniques to process used fuel salts into stable waste forms. Nuclear Data Areas of interest include improving nuclear data for actinides and chlorine, including neutron cross section refinement and covariance data for advanced nuclear fuels and reactors.

Advanced Manufacturing

Techniques to apply high-quality, corrosion resistant layers/coatings (carbides, nitrides, phosphides, refractory or noble metals, etc.) to high-temperature structural alloys for molten salt reactors. Techniques suitable for long heat exchanger tubes and complex geometries are especially desirable. Suitability for deployment in a high neutron flux environment is also desired. Tooling and techniques to support rapid replacement of used components to minimize outage intervals. Instrumentation Low uncertainty heat balance instruments and measurement techniques (mass flow and temperature difference) for utility scale molten salt coolant lines. Rapid quantification instrumentation and techniques for residual fissile materials on used components and filters being removed from the reactor containment. Plant instrumentation to assess the composition (corrosion products, actinide isotopes, tritium, oxygen) of small, periodically withdrawn, highly radioactive fuel salt samples. Techniques and tooling to support remote replacement or recalibration of sensors within a high-radiation containment.