Difference between revisions of "201307 R1ProgressRep"

Jump to navigation

Jump to search

| Line 11: | Line 11: | ||

crimpers are gapped at 0.3 mils (0.765 mm) every hour | crimpers are gapped at 0.3 mils (0.765 mm) every hour | ||

| − | =7/ | + | =7/08/13= |

| − | Dion: String S3 with Debbie | + | Dion: String S3 with Debbie, taking afternoon off |

Haitham: String S2 with David | Haitham: String S2 with David | ||

| Line 24: | Line 24: | ||

| − | S2: on Sense wire row | + | S2: on Sense wire row 109 |

| − | S3: on Sense wire row | + | S3: on Sense wire row 163 |

| + | |||

| + | S5, guard, crimped part was 0.043", uncrimped pin 0.065 ". | ||

[[CLAS12_R1_Progress_Reports]] | [[CLAS12_R1_Progress_Reports]] | ||

Revision as of 16:44, 8 July 2013

7/04/13

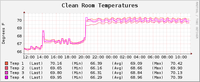

Clean room HVAC Low temperature alarm went off. Charts show that at 4am the temperature started dropping from 68 to 66 at noon.

Changed set point from 67 to 68.

The temperature monitor indicates that the temperatures went back to 70 degrees by 8pm.

crimpers are gapped at 0.3 mils (0.765 mm) every hour

7/08/13

Dion: String S3 with Debbie, taking afternoon off

Haitham: String S2 with David

David: String S2 with Haitham, install octopus on S5 SL2 and start HV burn in

Debbie: String S3 with Dion

Carlos: wire tension measurments, work on analyzing data to determine efficiency

S2: on Sense wire row 109

S3: on Sense wire row 163

S5, guard, crimped part was 0.043", uncrimped pin 0.065 ".