X-pinch driver 2-bricks fabrication

Progress Reports

December 08, 2013

- The updated drawing of bricks with remeasured front plate's holes created (drawing #2013.1.001.0001)

December 09, 2013

- The list of possible manufacturing company for Brick's Housing (BH) parts production is established:

- Partner Steel Co, Inc, Pocatello;

- Valley Sheet Metal (VSM) Technologies, Idaho Falls;

- Primear Technology, Blackfoot;

- Northwest wire EDM, Spokane, WA;

- Nelson Metal Technology, Payette, ID;

- Water Jet Cutting, Albuquerque;

- All above companies have been contacted for quotes. Criteria were price and speed of production.

December 10, 2013

- Brick's Housing (BH) parts (steel/AL/PMMA sheets) drawings is approved by Spielman (drawings #2013.1.001.0002-0009)

December 11, 2013

- VSM Technologies: selected as manufactured company for BH parts (drawings #2013.1.001.0002-0009)

December 17, 2013

- BH parts arrived at IAC and inspected. Kevin is going to assemble and weld them all together.

December 18, 2013

- Cathode/anode drawings submitted to Spielman for approving (drawings #2013.1.001.0010-0017)

- PMMA_Output_Sheet/Charging_Isolating_Tube drawings submitted to Spielman for approving (drawings #2013.1.001.0018-0019)

- X-pinch driver assembly drawing with included cathode/anode submitted to Spielman for approving (drawing #2013.1.001.0020)

- PARKER's Viton O-rings V0769-60 2-246 (2 pcs), ID 4 1/2 and W 1/8", selected for vacuum seal inside the cathode/anode section.

December 19, 2013

- LESKER reduced 4-way cross (C-0800-275, $890) found as a candidate for vacuum chamber [1];

- LESKER reduced 4-way cross drawing downloaded and incorporated into SolidWorks (assembly file Lesker_C-800_275\C-0800-275_reassembled);

- LESKER reduced 4-way cross redesigned to match our x-pinch driver (drawing file Lesker_C-800_275\2013.1.001.0030);

December 20, 2013

- Some changes to parts have been done to accommodate LESKER redesigned cross:

- 1) for Al output plate, the inner cut increased from 4.5 diameter to 10" diameter to match the cross (drawing #2013.1.001.0008);

- 2) for anode can, the slot size increased from 0.4" to 0.5" to march x-pinch wires length (drawing #2013.1.001.0014);

- Reassembled LESCER cross drawing submitted to Spielman for approving (drawing LESKER C-0800-275_REASSEMBLED)

- X-pinch driver assembly drawing with included cathode/anode/cross submitted to Spielman for approving (drawing #2013.1.001.0021)

- LESCER cross and new assembly drawings is approved by Spielman:

December 30, 2013

- LESKER reduced 4-way cross (C-0800-275, $890) is ordered [2]. Expected delivery id January 16, 2014. Comments: this one we will cut and reassemble later in the way we need. Just to remind, I plan two use one 8" flange for plate connection, one 8" flange for x-pinch access and vacuum pump connection, one 2 3/4 flange for x-ray diagnostics and one 2 3/4 flange for x-ray output.

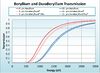

- for x-ray windows we can use Beryllium window (available from Moxtek in 1-1/3 and 2-1/8 CF flanges [3]).

For 2-1/8 CF flanges x-ray window, we will need Zero-Length Reducer Flange (from 2 3/4 to 2 1/8), like [4]

- can we use quartz window instead of beryllium? (we can probably borrow one from IAC stock);

- do we need RIGHT NOW x-ray window? A: no, we will need just glass viewport for x-pinch visual observation;

December 31, 2013

Other parts we need for vacuum chamber are:

- flanges:

- 8" fixed blank CF flange, Lesker part #F0800X000N, $125 [5]. Note: I would cut this flange in the middle to reduce the weight twice from 12 -> 6 lbs;

- 2 3/4" fixed bore 1.63" CF flange, Lesker part #F0275X175N, $15 [6]. Note: this flange will be used for x-ray diode's mounting;

- 2-3/4" CF flange viewport window. Note: this flange will be used for visual x-pinch observation. Later this flange can be replaced by x-ray window. Choose the cheapest (first) one:

- gaskets [10]:

- 1/4 Hard OFHC Copper Gasket for 2-3/4" CF flange, Lesker part #GA-0275, set of 10, $26.40;

- 1/4 Hard OFHC Copper Gasket for 8" CF flange, Lesker part #GA-0800, set of 10, $75.00.

- fasteners scroll down:

- 5/16—24 x 2-1/4" Bolt & Nut Set, Lesker part #HBS31224225, set of 25, $37.58 (for 8" flange up);

- 5/16—24 x 1-3/4" Bolt Kits, Lesker part #HBK31224175, set of 25, $30.60 (for 8" flange Al plate connection), (need 1" length);

- 1/4—28 x 1-3/8" Bolt & Nut Set, Lesker part #HBS25028138, set of 25, $29.38 (for 2-3/4" flanges);

- Total quote is xxx.xx plus shipping.

January 02, 2014

- Al output plate drawing #2013.1.001.0008 is updated to accommodate vacuum chamber's cross (11" cut changed to 8" and added slot cuts for small flanges);

- Reassembled Lesker cross drawing #2013.1.001.0030 is updated (file name changed and added some dimensions for clarity);

- Assembly drawing #2013.1.001.0021 is updated for clarity;

January 02, 2014

PMMA o-ring and groove design

- o-ring material we are needed:

- Viton (V1436-75, V1475-75, V1476-75);

- assumption made:

- viton = fluorocarbon;

- hardness we nee 70-80;

- o-ring size we are needed:

- nominal: ID=4-1/2, OD=4-3/4, W=1/8;

- actual: ID=4.484", W=0.139";

- Parker size number 2-246;

- o-ring we are needed:

- V1436-75 2-246;

- V1475-75 2-246;

- V1476-75 2-246;

- grove shape and size design:

- chapter 4.3, section IV - static o-ring sealing, Parker o-ring handbook.pdf:

- groove shape standard;

- ID=4.484", W=0.161", OD=4.806", Depth = 0.104", R=0.017", Finish = 16 RMS uinch;

- also see Eriks groove/o-ring calculator [11], pdf report File:03012014162515.pdf;

- assumption made:

- external pressure;

- ID(groove) = ID (actual o-ring size);

- o-ring deformation is about 25%;

- chapter 4.3, section IV - static o-ring sealing, Parker o-ring handbook.pdf:

- o-ring's grooves included into the PMMA drawing #2013.1.001.0018;

January 07, 2014

talked with R. Spielman:

- o-ring: the hardness of o-ring doesn't matter;

- gaskets:

- use Viton square gaskets for large flange instead of Cu, it could be used many times;

- cutting the large twice is OK;

- small flanges: using one blank and one veiwport is OK. Note: buy two blank (%15 each) and use viewport if available from IAV stock;

- vacuum chamber, anode, cathode drawings all are looking good;

parts we need to order extra for vacuum chamber:

- flanges:

- use Viton square o-ring to seal all flanges;

- fasteners, I will look at later;

January 10, 2014

talked with Kevin about vacuum chamber and anode/cathode:

- for vacuum chamber we need to order extra:

- 8" CF rotatable flange 6" pipe;

- 8" CF non-rotatable flange 6" pipe;

- 8" CF blank flange;

- Kevin recommended Duniway stockroom corp;

- order material (Grainger) and then we will do it at IAC;

- ask ParnerStill (Pocatello) about naterial, but they will probably ask what grade of brass we need;

- 8" flanges from MDC Vacuum have been ordered File:MDC Vacuum 011014.pdf:

January 13, 2014

x-pinch fabrication update

- vacuum chamber: all parts are ordered and after its arriving we start to fabricate the vacuum chamber;

- cathode/anode:

- should be approved? yes, and also need to include current monitor in anode cane drawing;

- identify and buy brass cuts; use naval/hard brass, should be easy to machined and inexpensive

- after vacuum chamber will be fabricated, update, if needed, drawings and fabricate anode/cathode parts;

- AL output plate (drawing 2013.0001.0008): need to modify;

- PMMA sheet output (drawing 2013.0001.0018): need to buy sheet and fabricate;

- charging isolating tube: need to buy rod and fabricate (how and who?)

- oil foamsm where to take?

- square viton o-ring: look at MDC Vacuum, or call them and ask for square Viton o=rinf for 8" flange

Found mistake in fabrication the Al output plate: the central whole is centered in all direction, but should not be. Need to make update of all drawings to reflect this fact;

- AL output plate drawing 2013.0001.0008 is updated to reflect real cut made in Al plate (done);

- Anode/cathode drawings need to be modified to reflect real cut made in Al plate (done):

- bricks has a freedom inside, mostly in horizontal directions. How we center cathode vs anode:

- make as reference plates the bottom and front of housing and update cathode plate drawing 2013.0001.0010 to center cathode vs anode;

- need some extra parts (tube ID=2" OD=2.5") for centering;

- where to include second current monitor?

- in anode can drawing 2013.0001.0010;

- make anode can thicker to have extra space for diagnostic mounting;

- Assembly drawings need to be modified to reflect real cut made in Al plate (do it tomorrow);

anode/cathode naval brass cuts need to be ordered (do it tomorrow):

- sheet 7" x 9" x 0.25"

- rod 1-1/8"(diam) x 1" (long)

- rod 2-1/8"(diam) x 10" (long)

- rod 4-1/2"(diam) x 10" (long)

January 14, 2014

- GOOGLE: BRASS SHEET;

- possible vendors: metal mart, online metal, metal deport;

- we need naval brass (ex. C464) or any hard brass. Should have a property of good machining and be also cheap;

X-pinch driver fabrication to do list

- Can we use cross instead of cube? (A: Cross - not, but reduced cross - yes);

- Do we need to use Cu gasket to seal CF flange? If so, we need a lot of them for every shot. (A: yes, we need to use Cu gaskets);

- X-pinch cathode/anode design and fabrication:

- Design x-pinch cathode/anode (in progress, drawings #2013.1.001.0010-0021 is finished and need to be approved by Spielman);

- Discuss possibilities of fabrication in IAC with Kevin (done);

- Order brass cuts;

- Fabricate anode/cathode/vacuum_chamber parts, drawings #2013.1.001.0010-0021;

- X-pinch vacuum chamber design and fabrication:

- Design x-pinch vacuum chamber, (done: drawings #2013.1.001.0021 (assembly) and 2013.1.001.0030 (Lesker reassembled cross));

- Include Al plate's taped holes in drawing #2013.1.001.0008 (done);

- Discuss reassembling possibilities with Kevin (done);

- Buy all parts for x-pinch vacuum chamber:

- Buy LESKER 8"/2-3/4" reducing cross (done: bought on 12/30/13, RACL60, expected delivery Jan 16, 2014);

- Buy 8" flanges (done);

- locate at IAC 2-3/4 flange and viewport (done: asked Kevin and he told we have some);

- Identify and buy gaskets/fasterners for cross;

- O-Rings:

- Identify o-rings (done);

- design o-ring groove (done);

- Include o-ring's grooves into the PMMA drawing #2013.1.001.0018 (done);

- Buy o-rings;

- Fabricate grooves inside PMMA output plate, drawing #2013.1.001.0018

- Identify/buy charging lines;

- Locate vacuum pump;

- Locate RG-214 (2-3 m);

- Diagnostics: Rogowskii and B-Dot:

- Read Rick's notes and paper;

- design and include in drawing;

- fabricate;