Difference between revisions of "Rotating Tungsten Target System"

Jump to navigation

Jump to search

| Line 34: | Line 34: | ||

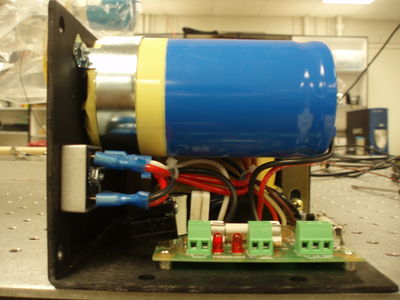

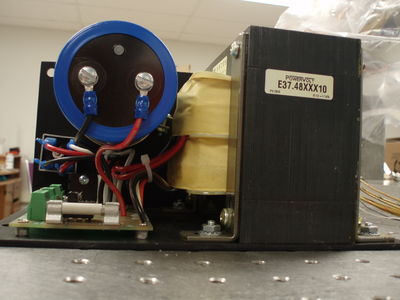

[[File:HRRL_Beam_Rot_Tar_Sys_Mot_PS1.png | 400 px]] [[File:HRRL_Beam_Rot_Tar_Sys_Mot_PS2.png | 400 px]] | [[File:HRRL_Beam_Rot_Tar_Sys_Mot_PS1.png | 400 px]] [[File:HRRL_Beam_Rot_Tar_Sys_Mot_PS2.png | 400 px]] | ||

| − | [[File:HRRL_Beam_Rot_Tar_Sys_Mot_PS6 | + | [[File:HRRL_Beam_Rot_Tar_Sys_Mot_PS6.png | 400 px]] [[File:HRRL_Beam_Rot_Tar_Sys_Mot_PS9.png | 400 px]] |

| − | |||

== Document == | == Document == | ||

Revision as of 06:30, 29 March 2012

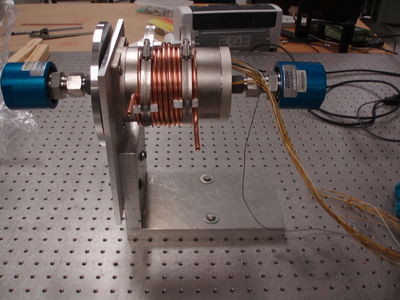

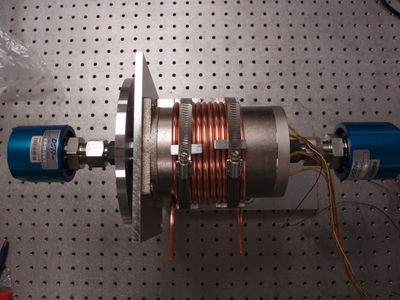

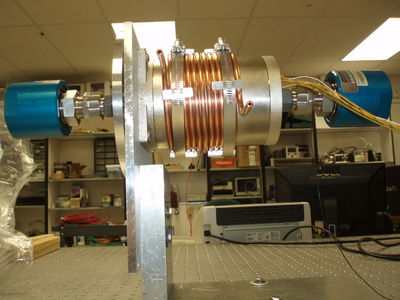

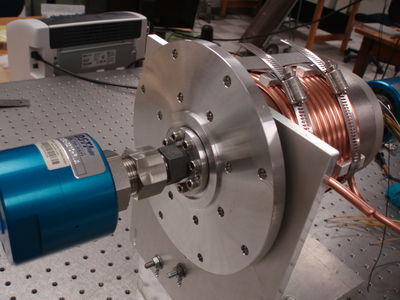

Parts

[More Images ]

Rotating Union

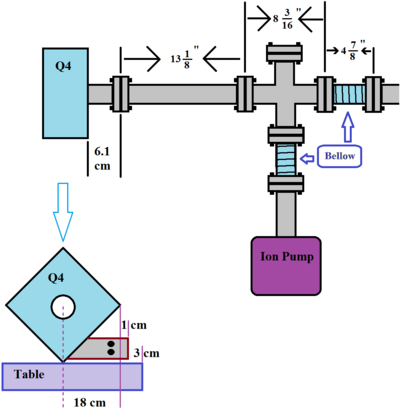

Positron Target Box

The pipe that go through quads has inner diameter: 47.38 * mm

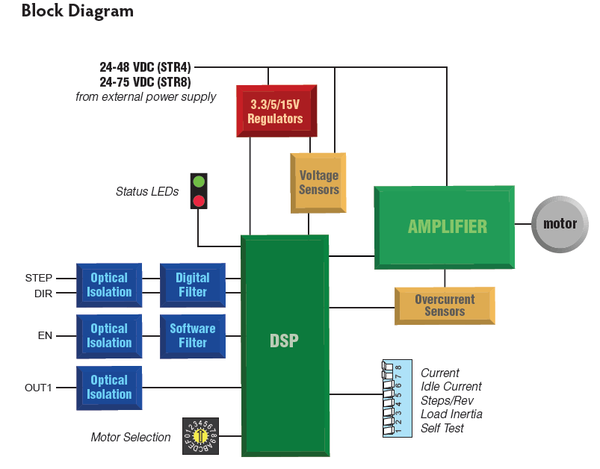

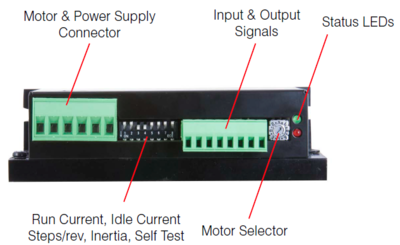

STR8 - Step Motor Drives

Applied Motion Products motor control.

Power Supply

Document

STR8 Manuals:

Media:STR_Quick_Setup_Guide.pdf

Datasheet:

Media:STR_Brochure_925-0002_RevC.pdf

2D Drawing:

Speed-Torque Curves:

Features

Operates from a 24 to 75 volt DC power supply

Running current up to 7.8 amps per phase

Other Parts needed

1) a 24 to 75 volt DC power supply

2) a source of step signals, such as a PLC or motion controller.

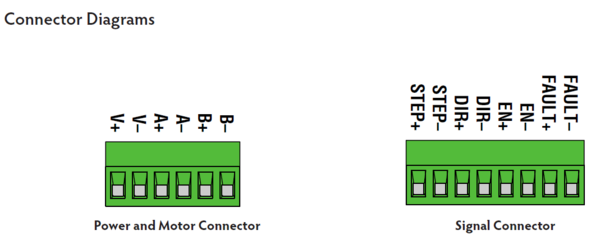

Wire Connection

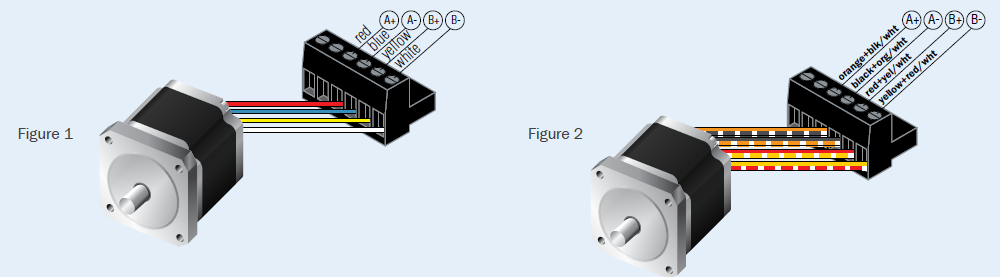

Wiring the Motor

Connect the drive to the motor. Four lead motors can be connected in only one way, as shown in Figure 1. We recommend that eight lead motors be connected in parallel, as shown in Figure 2. If using a non-Applied Motion Products motor, please refer to your motor specs for wiring information.