Difference between revisions of "R3DC Report 2-08"

| Line 21: | Line 21: | ||

:<math>t = 0.05 m \equiv</math> thickness of the endplate | :<math>t = 0.05 m \equiv</math> thickness of the endplate | ||

| − | A deflection of 6 mm is expected for a 5 cm thick Aluminum endplate after solving the equation for <math>y</math> and inserting the above values. If a 5 | + | A deflection of 6 mm is expected for a 5 cm thick Aluminum endplate, after solving the equation for <math>y</math> and inserting the above values. If a 5 cm thick stainless steel <math>(Y=2 \times 10^{11} N/m^2 )</math> endplate were used, the deflection would drop from 6 mm to 2 mm. The amount of deflection does not substantially decrease when stainless steel is used despite its larger Young's Modulus. The cubic dependence of the deflection on the thickness of the endplate is used to reach the minimum endplate deflection criteria of 50 \<math>mu m</math> instead of using stiffer material. Composite materials were considered in order to increase the thickness of the material without substantially increasing the weight of the endplate. |

[[Image:2-D.jpg | 400 px]] | [[Image:2-D.jpg | 400 px]] | ||

Revision as of 16:57, 7 February 2008

Introduction

R3 Description

Geometry

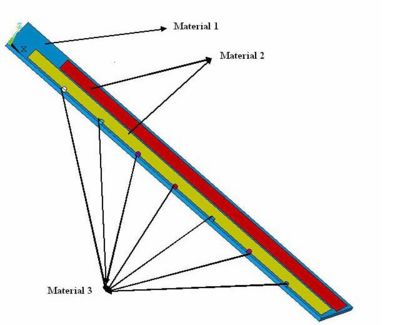

Material Specifications

Specific part Drawings

Endplate Deflection

Point Load Deflection

A simple calculation based on the definition of Young's modulus can yield and order of magnitude level estimate for the deflection an endplate made from Aluminum. According to the definition of Young's modulus

where

- Young's Modulus for Aluminum

- point force/load

- width of the endplate

- deflection of endplate due to point force

- length of the endplate

- thickness of the endplate

A deflection of 6 mm is expected for a 5 cm thick Aluminum endplate, after solving the equation for and inserting the above values. If a 5 cm thick stainless steel endplate were used, the deflection would drop from 6 mm to 2 mm. The amount of deflection does not substantially decrease when stainless steel is used despite its larger Young's Modulus. The cubic dependence of the deflection on the thickness of the endplate is used to reach the minimum endplate deflection criteria of 50 \ instead of using stiffer material. Composite materials were considered in order to increase the thickness of the material without substantially increasing the weight of the endplate.

| Material | Youngs Modulus | Density |

| MPa | ||

| Polyeurethane Foam FR-3700 | 140 | 240 |

| Hexacell with holes | ||

| Carbon Fiber Rods | 210 | 580 |

Distributed Load Deflection

Distributed load FEA

Carbon Rod Buckling

Compression

Buckling Load Threshold

Buckling FEA

=3-D Analysis