Progress reports

R3 design Progress report

3/11/08

Progress modeling the R3 drift chamber has been held back by both software and hardware problems. This past week we installed ANSYS on a faster computer ( 2 GHz Intel with 3Meg RAM) and were able to render the design in 30 minutes instead of 2 hours. The turnaround for debugging the geometrical design is now faster and ANSY does not currently crash. We plan on doing the same test using a new computer (2 GHz Intel with 8 Meg RAM) once it has been assembled (2 weeks or less).

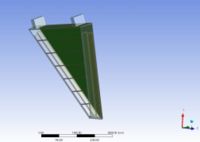

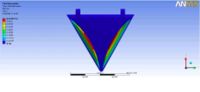

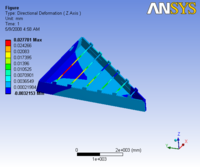

The image below represent the current Model which has been implemented in ANSYS.

3/18/08

1.) Movies showing deflections as a function of applying the max load and then releasing it. The max deflection is about 13 mm. The two movies below show the two endplate deflections with no rods for either 1 fixed or 2 fixed mount points.

This movie shows the endplate deflection as the wire load is applied and then released. The top two mounting brackets on the back plate are fixed.

The movie below is under similar conditions except the right bracket is allowed to move.

2.) The Max deflections decreases from 13 mm to less than 1 mm if carbon fiber rods are place along the front edge of the endplates. The back plate hinges are both fixed.

http://www.jlab.org/Hall-B/secure/clas12/RIII/ISU_Design/images/Deflection_Rods.avi

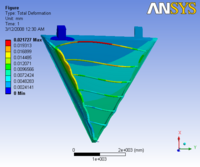

3.) The image below shows a max end plate deflection of 0.3 mm when hexcell backing sheet is used and No carbon fiber rods.

File:Deflection Hexel 2fixedMounts.pdf

File:Deflection Hexel 2fixedMounts.pdf

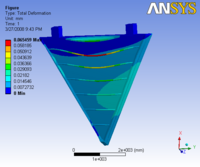

4.) A max deflection of 22 microns for the carbon rods and less than 20 microns for the endplate is predicted from our current ANSYS model when both carbon fiber rods and a hexcell backing sheet are used. Only the left hinge is constrained completely and the right hinge is constrained in 2 degrees of freedom. No gravity and no differential gas pressure. Effective Youngs modulus is used. The carbon fiber rods and the hexcell backing sheet are the only materials not made from the poly foam composite. Poly foam used on endplates, back plate, and nose plate. No Al frame around endplate.

3/25/08

5) The max endplate deflection increases from 20 to less than 22 microns when gravity is added. Both the carbon fiber rods and a hexcell backing sheet are used.. The carbon rod deflection increases from 22 to 65 micron with the addition of gravity. Only the left hinge is constrained completely and the right hinge is constrained in 2 degrees of freedom. Gravity is applied along the direction from the back plate towards the Nose plate. The material properties is same as analysis 4

Media:Deflection_with gravity_3-12-08.pdf

Media:Deflection_with gravity_3-12-08.pdf

Problems meshing 0.001 inch thick mylar sheet front window. I am able to mesh a XXXX thick sheet. So I adjust Young's Modulus accordingly.

4/14/08

The R3 design is converging to a configuration which results in a max end plate deflection less than 25 microns and more than a factor of 2 smaller than the specifications according to a three dimensional ANSYS model. The effects of gravity are included in this estimate. The impact of the differential pressure has not been included in the model. Attempts to insert a front mylar window into the model and apply a pressure were not successful. A hand calculation will be performed at this time to estimate the effects. The first estimate will consider the force exerted on the carbon rod due to the gas pressure. Is the force exerted by the mylar sheet onto the carbon rod enough to cause the rod to buckle? A second estimate will assume that the carbon rod does move and then distribute the mylar sheet load uniformly along the edges assuming the force produced by the pressure is in the same direction as the wire tension.

4/22/08

The endplate dimensions have been changed this week and were implemented. Bob Miller asked Kalyan to at the effects of the change instead of moving on to the impact of differential pressure.

4/29/08

Bob asked Kalyan to make the changes below to the Drift Chamber design and redo the base analysis(Frame + rods, No Hexcel, no mylar).

1.)Replaced effective Young's modulus with actual layers of SS and polyurethane foam.

2.)Added an Aluminum frame around polyurethane foam

3.) added AL ears onto end plate sides for carbon fiber rods (now rods push against Al instead of foam sandwich)

4.) Dimensions of End plates where changed with the change of widths of super layers; Upstream super layer width from 210.96mm to 188.34mm and downstream super layer width from 210.88mm to 192.42mm

5.) Front face of Nose plate is constrained completely and not floating in space.

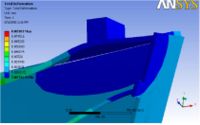

The wire tension was applied and the Max end plate deflection changed from 1.17 ( as shown in Table 5.2.1 of the original report, Analysis 3.1) to 0.85 mm.

When Max gravity is applied the end plate Max deflections changes from 0.85 to 3.7 mm.

The orientations and results were shown at the following link Kalyan_4-25-08

Need to freeze design so drawing can begin. Can JLab freeze the design by 5/22/08?

5/6/08

Fixed the following errors in the ANSYS design

1.) Mass is ~350 kg (back plate is poly + SS)

2.) Wire load directions are at 6 degrees now

Remaining problems/tasks

1.) Back plate deflection shows that Back plate is not completely attached to endplate

2.) Hinges are no longer applicable to design. Substitute constraints directly on the Back plate region where the hinges are.

3.) Make back plate and end plates separate parts to limit contact regions

4.) Change Hexcell exit window into two pieces ( 1 carbon fiber and the other the honeycomb). This will remove need for using effective Young's Modulus.

5.) refine the end plate mesh to improve deflection resolution

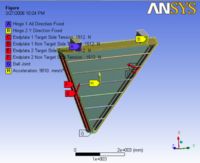

- Hinge constraints. The coordinate system has the Z- axis along the beam line, and the Y-axis pointing towards the chamber back plate.

| Mount point | Constraint |

| Right Hinge (B) | X,Z |

| Left Hinge (A) | Y,Z |

| Nose plate | X,Z |

5/13/08

The following questions from last week have been addressed.

1.) Back plate deflection shows that Back plate is not completely attached to endplate

Bob Miller sent an image showing thay the back plate was not a completely attached to the endplate.

When Kalyan zooms into the same region he does not see a discontinuity.

This seems to illustrate a software problem. ANSYS seems to be able to generate differences in a Model when opened by different users using different computers. It has been suggested that the environment settings on a particular machine can result in auto connections being created different. Apparently something about Bob's environment setting is not allowing ANSYS to automatically generate a connection between the backplate and endplate like Kalyan's ANSYS environemnt is doing.

2.) Hinges are no longer applicable to design. Substitute constraints directly on the Back plate region where the hinges are.

3.) Make back plate and end plates separate parts to limit contact regions

4.) Change Hexcell exit window into two pieces ( 1 carbon fiber and the other the honeycomb). This will remove need for using effective Young's Modulus.

5.) refine the end plate mesh to improve deflection resolution

Problems 2, 3, 4, 5 were addressed and updated at the table of contents section at http://www.iac.isu.edu/mediawiki/index.php/R3DC_Report_2-08#Table_of_results

| Analysis | Sector Orientation | Hinge A constraint | Hinge B Constraint | Nose Plate | |

| Sector 1 | Analysis 1.1 | 1 | Y,Z | X,Z | X,Z |

| Analysis 1.2 | 1 | X,Z | Y,Z | Y,Z | |

| Sector 4 | Analysis 4.1 | 4 | Y,Z | X,Z | X,Z |

| Analysis 4.2 | 4 | X,Z | Y,Z | Y,Z |

| Deformation (mm) | ||||||

| Analysis | E Max | D Max | X Max | Y Max | Z Max | |

| Sector 1 | Analysis 1.1 | 0.041 | 0.041 | -0.038 | 0.026 | 0.016 |

| Analysis 1.2 | 0.110 | 0.110 | -0.107 | -0.037 | 0.045 | |

| Sector 4 | Analysis 4.1 | 0.056 | 0.056 | 0.051 | 0.031 | 0.027 |

| Analysis 4.2 | 0.107 | 0.107 | 0.107 | 0.032 | -0.043 |

After looking at the results, analysis 1.1 and analysis 4.1 were observed with the least deflections for sector 1 and sector 4 respectively. So, these results were refined by

1. Refining the mesh size.

2. Sandwiching the Hexcel backing sheet with carbon fiber slices.

3. Removing the hinges and applying the constraints over the hinge area.

4. Making single parts for each end plates.

| Deformation (mm) | ||||||

| Analysis | E Max | D Max | X Max | Y Max | Z Max | |

| Sector 1 | Analysis 1.1 Refined | 0.043 | 0.043 | -0.040 | 0.027 | 0.027 |

| Sector 4 | Analysis 4.1 Refined | 0.040 | 0.040 | 0.036 | 0.027 | 0.019 |

- Summary

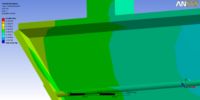

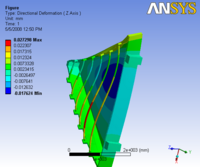

- The above analysis indicates that the nose plate should be constrained in the "X" direction for the least endplate deflection. There is an unusual deflection pattern observed when the exit window part is meshed ("refined" analysis). The exit window deflection is observed to have oval concentric contours when the Hexcell + carbon fiber composite exit window is treated as a single material with an effective young;s modulus. The contours look very different if the three parts of the exit window (carbon fiber + Hexcell + carbon fiber) are meshed separately with their respective Young's modulus.

| Before Meshing | After Meshing |

| Effective Young's modulus | Separate Young's Modulus |

|

|

Next week:

1.) deflections for other sectors. Table has deflection of the wire.

2.) Why does the mesh deflection look unnatural. In analysis 1.1 defections in the Z direction form circular like contours. Analysis 1.1 "refined" though has Z deflections which have contours that are very different. Perhaps there is a problem with the meshing