Difference between revisions of "PbFl RadTests-12-3-07"

| Line 96: | Line 96: | ||

|- | |- | ||

| 100 | | 100 | ||

| − | | | + | | 25.5(30.413) |

| − | | | + | | 393(35.44) |

|- | |- | ||

| 150 | | 150 | ||

Revision as of 20:02, 3 December 2007

Day 1. December 3, 2007. MONDAY

Shift Personnel

| Collaborator | Shift |

| Amine | 8-10 am , 2-4 pm |

| P. Bertin | 8am - 5 pm |

| Syed | 8 am - noon |

| T. Forest | 10 am - 2pm |

Task 1: Tune Beam

The first task will be to establish reproducable running conditions using the beam parameters given on the Main page.

This ask will also require that the FC and Pickup Coil be positioned and operating as well.

Task 2: Emmittance

Once stable beam operations are in place, we will insert two glass slides on the translator platform positioned 10 and 30 cm away from the Aluminum cooled exit window. Put beam on the windows and watch on the camera until the glass slides change color showing the beam envelope.

Next move the translator board to align the large glass plate at 50 cm away from the window and measure the beam profile

Glass Slides at 10 cm, 30 cm, and 50 cm.

Brett says the electron beam is focused to 1 mm in diameter before it strikes the exit window. After it passes throught the water-cooled exit window (Al 1mm - Water 1mm - Al 1mm), the beam swells to 6.0mm and at 30cm it the beam spot size is 2cm.

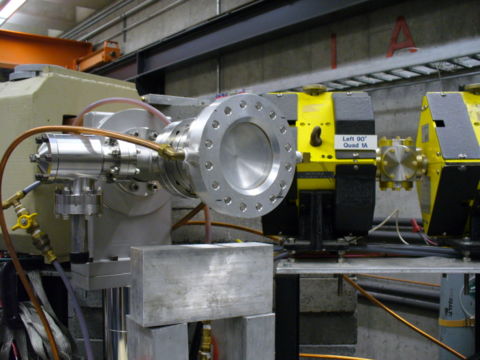

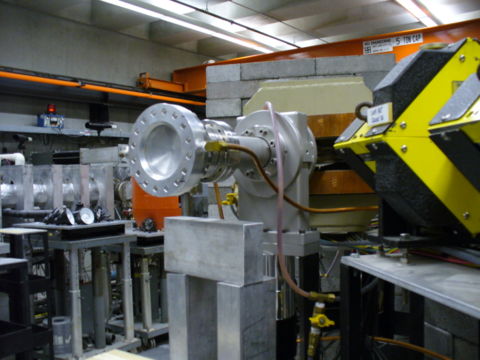

Here are two views of the exit window

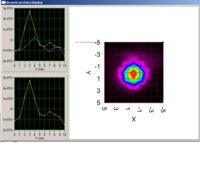

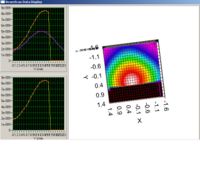

Beam spot size mapping in x and y with the Faraday Cup (FC) for z = 30cm from Window.

We will move the table in or out depending on whether the beam spot size is greater or smaller than 2.0 cm. Translator table will be positioned at right position in z.

Course scan of z=15cm

Course scan of z=15cm was taken away from the Al window with dimensions in inches and the intensity measured in Volt ns

Data file for the above picutre is comma deliminated and formated as X,Y,Z. I belief X (Beam left/right), Y is beam Up/Down, and Z is the integrated scope output (in 50 ) with units of (Volts ns )Media:PbF2_FineeScan_Z-15cm.dat.txt

Task 3: Linearity tests of the pickup coil and FC.

We will just change the width of the pulse and compare the readings from the pickup coil to that of the FC. Note that change in 1mV from the pickup coil corresponds to 1mA change in the instantaneous beam current.

The beam energy may change if we change the pulse width so we decided to change the frequency

Beam at 50mA peak, 100 ns, and at the frequency given in the table below below

The pick up loop was a split signal between MCC and Us so you need to multiple by 2 for an absolute measurement

The FC was not split.

| Frequency (Hz) | pickup coil (P2P mV) | FC (mV) |

| 1 | 21.5 (26.1789 V ns) | 312 (28.4168 V ns) |

|

10 |

23.4 (27.8362) | 359 (32.132 ) |

|

20 |

24 (28.668) | 368 (33.177) |

| 30 | 24.3 (29.093) | 371 (33.67) |

| 50 | 24.2(28.708) | 369(33.025) |

| 100 | 25.5(30.413) | 393(35.44) |

| 150 | ||

| 200 | ||

| 250 | ||

| 300 |

300 Hz is max without increasing width

| Pulse Width (us) | pickup coil (mV) | FC (mV) |

| 0.08 | PC | FC |

|

0.10 |

||

|

0.16 |

||

| 0.30 | ||

| 0.50 | ||

| 0.75 | ||

| 1.00 | ||

| 2.00 |

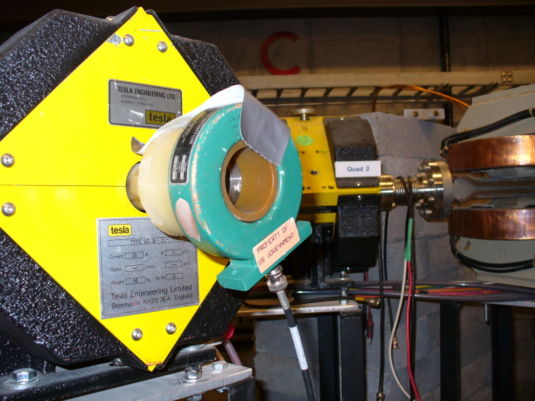

Here are Pictures of the Faraday Cup and the Pickup Coil

Task 4: 5 hours of beamtime

Recall that we cannot exceed 10 K/h

- Irradiate broken PbF2 Crystal for 0.5 h and check the rate of the rise of temperature.

We will use a Fluke monitor with a camera to look at the temperature.

1 Watt power at 30 cm away from window

Using beam conditions of 50 mA, 10 Hz, 100 nsec pulse width we ran for 10 minutes and looked for temperature change.

Starting temp: C

after 600 seconds : C

3 Watt power at 30 cm away from window

Using beam conditions of 50 mA, 30 Hz, 100 nsec pulse width we ran for 10 minutes and looked for temperature change.

Starting temp: 23.8 after 300 sec: 24.8 after 600 seconds :26.05 Beam off

Equilibrated to 26.8 after beam off

| Time (sec) | Temp (C) |

| 0 | 26.8 |

| 60 | 26.1 |

| 120 | 25.8 |

10 Watt power at 30 cm away from window

Using beam conditions of 50 mA, 100 Hz, 100 nsec pulse width we ran for 10 minutes and looked for temperature change.

Starting temp: after 600 seconds :

- Place Crystals 1, 2, 3, 4 on translator table.

#Crystal 1: 0.5 hours

# Crystal 2: 1 hour

# Crystal 3: 1 hour

# Crystal 4: 2 hours

- Transparency Test (~3 hours)

- Blue Light curing (24 hours)