Difference between revisions of "Niowave Report 11-30-2015"

| Line 7: | Line 7: | ||

==Optimal Thickness== | ==Optimal Thickness== | ||

| − | A 10 MeV electron beam with a 1cm radius uniform cylindrical spatial distribution | + | One method to produce positrons relies on the creation of positron-electron pairs from the bremsstrahlung photons that are produced when electrons traverse a dense material. While thicker material encourages the production of these photons, the increased thickness will also cause the produced positrons to annihilate within the material before they can escape. As a result, there is an optimal thickness which will balance the two processes to maximize positron production. A simulation was performed to determine the optimal thickness using a 10 MeV electron beam with a 1cm radius uniform cylindrical spatial distribution impinging a windowless PbBi target. The target thickness was changed to determine the optimal thickness to emmitt positrons from the downstream surface of the PbBi target. |

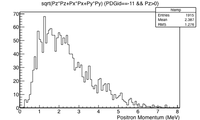

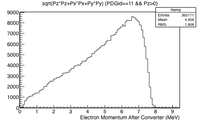

[[File:PbBi_5-1-15_Ppositron.png | 200 px]][[File:PbBi_5-1-15_Pelectron.png | 200 px]] | [[File:PbBi_5-1-15_Ppositron.png | 200 px]][[File:PbBi_5-1-15_Pelectron.png | 200 px]] | ||

Revision as of 19:25, 28 November 2015

Overview

10 MeV electron beam

3.48 cm diameter beam pipe

Target optimization

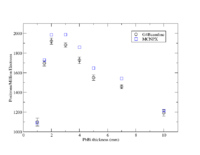

Optimal Thickness

One method to produce positrons relies on the creation of positron-electron pairs from the bremsstrahlung photons that are produced when electrons traverse a dense material. While thicker material encourages the production of these photons, the increased thickness will also cause the produced positrons to annihilate within the material before they can escape. As a result, there is an optimal thickness which will balance the two processes to maximize positron production. A simulation was performed to determine the optimal thickness using a 10 MeV electron beam with a 1cm radius uniform cylindrical spatial distribution impinging a windowless PbBi target. The target thickness was changed to determine the optimal thickness to emmitt positrons from the downstream surface of the PbBi target.

Optimal Solenoidal Field

Beam Pipe heating

The energy deposited by electrons scattered into a 3.48 diameter stainless steel beam pipe (1.65 mm thick) from a PbBi target as a function of a uniform Solenoidal magnetic field.

The histogram is binned in 100 (10 cm) bin widths. The surface area becomes

To convert From Mev/ e- to kW/cm^2 assuming a current of 1mA (10^-3 C/s) you

|

|

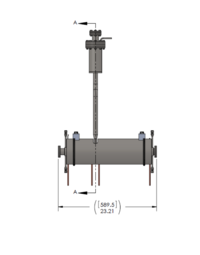

Solenoid Description

A 10 MeV electron beam with a radius of 0.5 cm was incident on a 2 mm thick PbBi target. The target is positioned at Z = -901 mm.