Difference between revisions of "IAC FC Scanner Amine and Syed"

(Created page with '1. Attatch power cables to the translator system, contact any IAC personnel. 2. Take any cable, e.g, 223A3, and connect it to the Faraday Cup (FC) and properly ground it. FC...') |

|||

| (12 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | 1. | + | 1. Hook power cables to the translator system, contact any IAC personnel. |

| + | Axis-1 cable: To move the translator system horizontally | ||

| + | Axis-2 cable: To move the translator system vertically | ||

| + | |||

| + | 2. Take any RG-223 cable, e.g, 223A3 (already in the accelerator hall), and connect it to the Faraday Cup (FC) and properly ground it. | ||

| − | + | 3. Follow the following (this step is important for signal acquisition purposes during beam scan/beam profiling): | |

| + | FC -> 223A2 -> Scope (Tektronix Oscilloscope: TDS3044-1) [Lets say Channel 1] | ||

| + | Linac Trigger -> 223D1 -> Scope (Tektronix Oscilloscope: TDS3044-1) [Lets say Channel 2] | ||

| − | + | 4. Manually align FC w.r.t beam axis. The rest of the alignment procedure will be done through beam scan. Reset Axis on MC-2000 controller: this is the reference FC position for now! | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | 4. Manually align FC w.r.t beam axis. The rest of the alignment procedure will be done through beam scan. | ||

5. 223D1 takes signal from linac's gun trigger. Observe the shape of the pulse on Oscilloscope, if beam is not properly tuned or any cable is not properly terminated then the shape of the pulse will not be rectangular in shape. Always show shape of the pulse to the operator. | 5. 223D1 takes signal from linac's gun trigger. Observe the shape of the pulse on Oscilloscope, if beam is not properly tuned or any cable is not properly terminated then the shape of the pulse will not be rectangular in shape. Always show shape of the pulse to the operator. | ||

| Line 19: | Line 20: | ||

These two steps will connect to the translator system, reset the Axis on MC-2000 controller | These two steps will connect to the translator system, reset the Axis on MC-2000 controller | ||

| − | 8. Figure out the movement of the FC for each arrow. | + | 8. Figure out the horizontal and vertical movement of the FC for each arrow. |

| + | |||

^ | ^ | ||

| | | | ||

| Line 28: | Line 30: | ||

'''Beam Scan''' | '''Beam Scan''' | ||

| − | 1. Click "Connect" in Pulse Recording Software, this will initialize the beam scan procedure. | + | 1. Click "Connect" button in Pulse Recording Software, this will initialize the beam scan procedure. |

2. Acquire -> Beam Scan | 2. Acquire -> Beam Scan | ||

| Line 38: | Line 40: | ||

Measurement Settings: 32 (Area) | Measurement Settings: 32 (Area) | ||

| − | 4. Click "Go" to start the beam scan procedure. | + | 4. Click "Go" button to start the beam scan procedure. |

5. Observe shape of the beam w.r.t x-y axis and approximately locate the position of the FC w.r.t beam axis. | 5. Observe shape of the beam w.r.t x-y axis and approximately locate the position of the FC w.r.t beam axis. | ||

| − | 6. If beam is not aligned then electronically translate the FC and reset Axis on MC-2000 controller. Close x-y axis plot before this step so translator system moves the FC to its | + | 6. If beam is not aligned then electronically translate the FC and reset Axis on MC-2000 controller: this is our new reference position. Close x-y axis plot before this step so translator system moves the FC to its previous reference. |

7. Repeat beam scan until beam is properly aligned. | 7. Repeat beam scan until beam is properly aligned. | ||

| Line 49: | Line 51: | ||

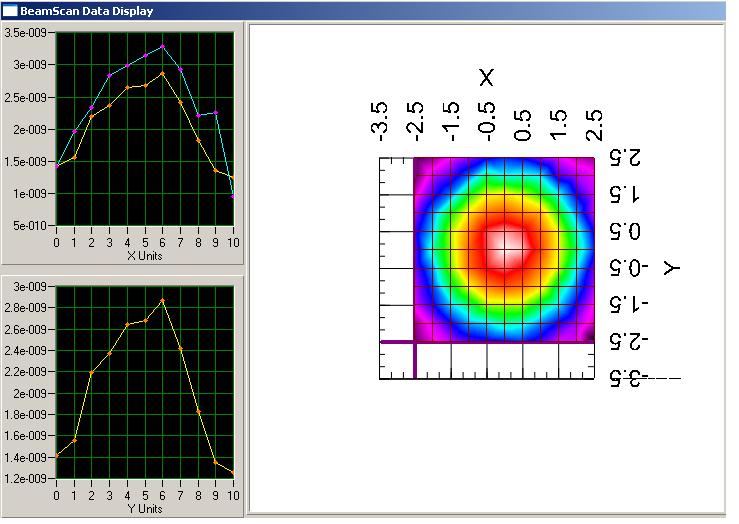

[[File:BeamScan-1.jpg]] | [[File:BeamScan-1.jpg]] | ||

| − | The distribution is approximately Gaussian because of | + | The distribution is approximately Gaussian because of "Beam Flattener" at the exit of the linac's beam port. |

| + | |||

| + | '''Comment:''' We need to take picture and parameters of the beam flattener: thickness and what material?? | ||

Latest revision as of 22:57, 8 December 2009

1. Hook power cables to the translator system, contact any IAC personnel.

Axis-1 cable: To move the translator system horizontally Axis-2 cable: To move the translator system vertically

2. Take any RG-223 cable, e.g, 223A3 (already in the accelerator hall), and connect it to the Faraday Cup (FC) and properly ground it.

3. Follow the following (this step is important for signal acquisition purposes during beam scan/beam profiling):

FC -> 223A2 -> Scope (Tektronix Oscilloscope: TDS3044-1) [Lets say Channel 1] Linac Trigger -> 223D1 -> Scope (Tektronix Oscilloscope: TDS3044-1) [Lets say Channel 2]

4. Manually align FC w.r.t beam axis. The rest of the alignment procedure will be done through beam scan. Reset Axis on MC-2000 controller: this is the reference FC position for now!

5. 223D1 takes signal from linac's gun trigger. Observe the shape of the pulse on Oscilloscope, if beam is not properly tuned or any cable is not properly terminated then the shape of the pulse will not be rectangular in shape. Always show shape of the pulse to the operator.

6. Power on two black boxes: one for translator power and the other one for the controller system (MC-2000 Controller).

7. Launch Pulse Recording Software and follow the following steps:

Motion -> Connect Motion -> Operate These two steps will connect to the translator system, reset the Axis on MC-2000 controller

8. Figure out the horizontal and vertical movement of the FC for each arrow.

^

|

<- ->

|

v

Beam Scan

1. Click "Connect" button in Pulse Recording Software, this will initialize the beam scan procedure.

2. Acquire -> Beam Scan

Horizontal Steps: 11" Step Size: 0.5"

3. Under "Acquisition Configuration"

Data Source: Software Management Measurement Settings: 32 (Area)

4. Click "Go" button to start the beam scan procedure.

5. Observe shape of the beam w.r.t x-y axis and approximately locate the position of the FC w.r.t beam axis.

6. If beam is not aligned then electronically translate the FC and reset Axis on MC-2000 controller: this is our new reference position. Close x-y axis plot before this step so translator system moves the FC to its previous reference.

7. Repeat beam scan until beam is properly aligned.

Beam Scan Example in inches (taken by Syed and Carlos on Dec. 07, 2009)

The distribution is approximately Gaussian because of "Beam Flattener" at the exit of the linac's beam port.

Comment: We need to take picture and parameters of the beam flattener: thickness and what material??