Difference between revisions of "Detector Description"

| Line 37: | Line 37: | ||

| − | [[File:modified_GEM_pic.png | | + | [[File:modified_GEM_pic.png thumb |alt=Example alt text|Adding modifications to GEM design. | 300px]] |

Go Back [https://wiki.iac.isu.edu/index.php/Performance_of_THGEM_as_a_Neutron_Detector#Detector_Description | Go Back [https://wiki.iac.isu.edu/index.php/Performance_of_THGEM_as_a_Neutron_Detector#Detector_Description | ||

Revision as of 21:03, 17 October 2013

GEM Detector Design

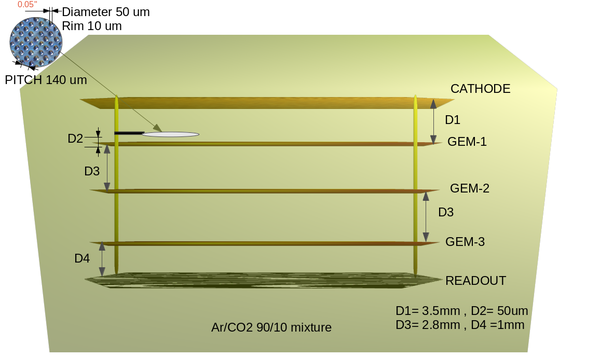

Detectors are very sensitive devices, its components are connected to high voltage power supplies in a relatively thin chamber with Ar/CO2 90/10 gas mixture. As a result, the method of construction and maintaining demands a laminar flow hood that accommodates a clean environment from any source of dust in the atmosphere or any surrounding objects, Also the gloves are used to avoid any particle transfer to the detector's components through the steps of its construction or testing.

The GEM based neutron detector consists of :

1- A cathode; a square copper plate has a dimension of 10x10cm and has a distance of 1.2 cm from the top of the fist GEM card. The cathode design allows to raise the potential on its surface up to 5 kV (in air) without any discharge effect.

2- A neutron sensitive material; in our case U-233 have been used as a sensitive material and has relatively a high fission cross in the desired energy range, U-233 is coated on the top of a metal plate in circular disk that has a diameter of 3cm and fixed as a part of the detector cathode's surface.

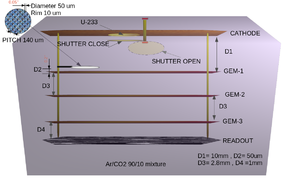

3- GEM cards; the detector has three GEM cards in square plastic frames, they have dimension of 10x10cm and are placed parallel to the cathode as shown in the figure below.

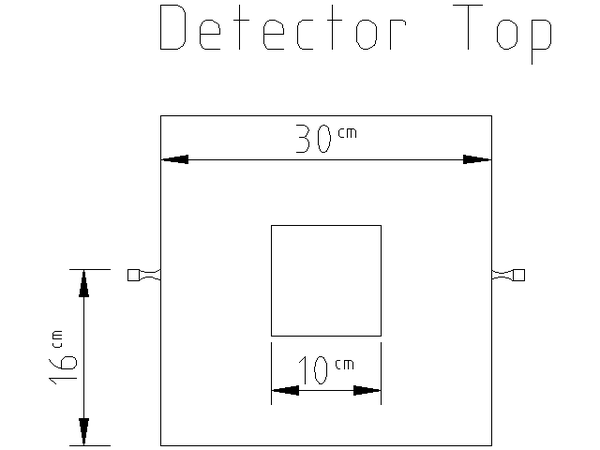

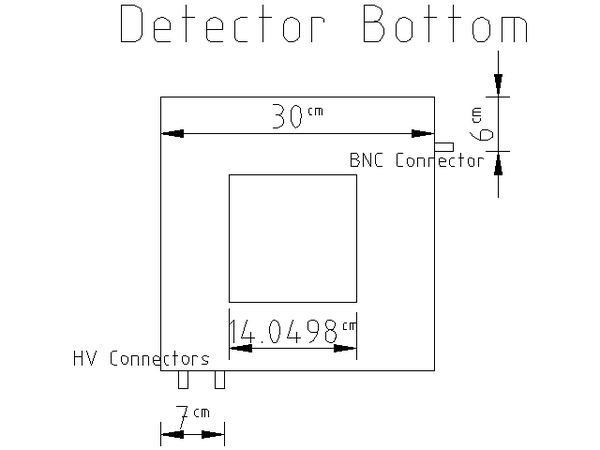

Insert drawing with dimensions so someone can build a copy of your detector.

Each GEM preamplifier is made of a copper clad kipton plate of a thickness 50 um and an area of 10x10cm, It has holes with a diameter of 50 um and 10 um rim which are chemically etched in an equilateral triangular pattern with 140 um pitch distance.

4- A sealed chamber; All the previous components exist in a chamber that consists of two ertalyte plastic sheets , they are bolted together by a number of M3 plastic screws located around the detector window to form a well closed cavity around the GEM cards away from the surrounding atmosphere. The purpose of sealant is to insulate the chamber's gas from the surrounding atmosphere gas components. Also, the chamber has a square window of kipton of dimension of 13x13cm.

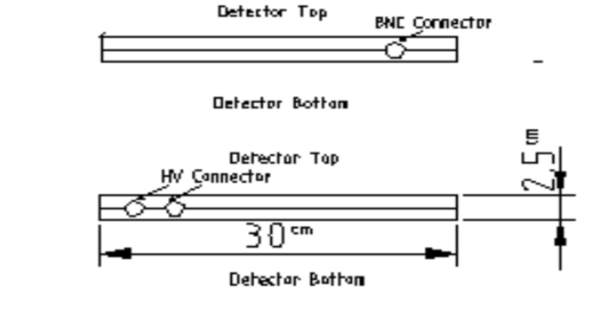

The figures below show top, bottom and side view of the detector design.

Modifying the GEM detector as neutron sesitive detector

The GEM original design is modified to convert it to a neutron sensitive detector. One of changes is in the cathode design, it has a circular coating of U-233 with a diameter of 3 cm and 40-50 um thickness. Also the distance of the cathode from the first GEM becomes 8 mm instead of 3.5 mm. The kepton window's height increased to 2.5 mm, it helps to avoid any direct contact with the cathode when it is located to the new height. The figures below show the modified detector design.

Go Back [https://wiki.iac.isu.edu/index.php/Performance_of_THGEM_as_a_Neutron_Detector#Detector_Description