Difference between revisions of "DDP:Detailed Design Phase: Drawing and Assembly Package"

| Line 183: | Line 183: | ||

There are 6 Carbon rods each of outer diameter of 50.8 mm and inner diameter of 48.26mm | There are 6 Carbon rods each of outer diameter of 50.8 mm and inner diameter of 48.26mm | ||

| + | |||

| + | A detailed drawing of carbon fiber rods can be viewed at [[Image:assembly20_jun_16.pdf]] | ||

| + | |||

| + | |||

[http://www.iac.isu.edu/mediawiki/index.php/R3#Timeline Go Back] | [http://www.iac.isu.edu/mediawiki/index.php/R3#Timeline Go Back] | ||

Revision as of 01:30, 26 June 2008

Detailed Design Drawing Report 6/27/08

Outline:

1.) Dimensions

2.) Constraints: Case 3 from progress report: constrain triangle and nose plate on upstream side.

3.) Deflection Analysis

Steps:

a.) check triangle contact region and its mass b.) add another carbon fiber rod c.) increase size of back plate

4.) Drawings

drawings in PDF format

a.) Endplate structural drawing (no holes just shaded area)

b.) Drawings for all other parts

c.) drawing showing how parts are bolted together

d.) Copy old R3 (take advantage of no curved window.

Report

Basic understanding

This section of the report will deal with the basic understanding of the region 3 in the nuclear Drift Chamber. This is where the required geometric parameters are understood.

Initial parameters to be followed to fulfill to satisfy design Criteria

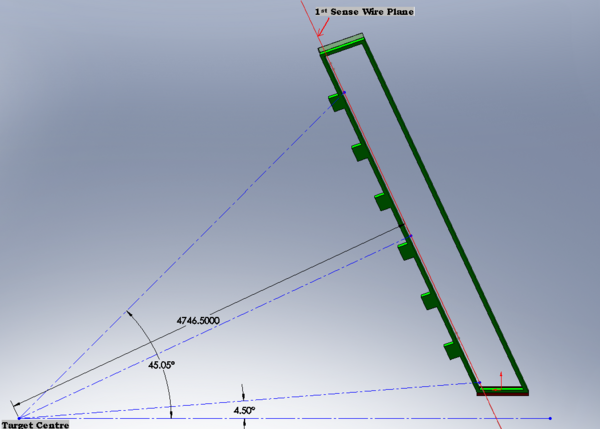

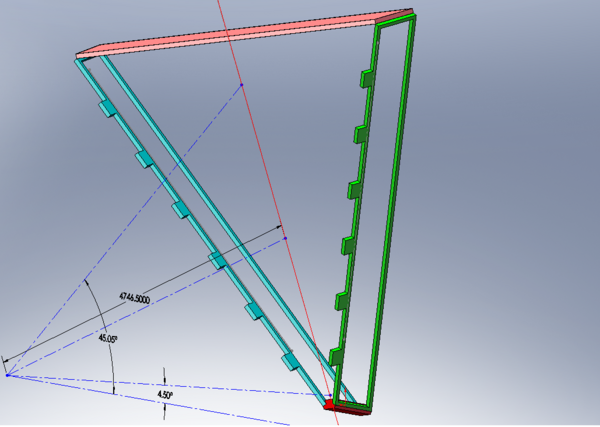

1. Distance from target to first sense wire plane along a ray which is normal to the end plate = 4746.5 mm

2. Chamber Tilt Angle = 25 Degrees

3. Maximum Scattering Angle = 45.05 Degrees

4. Minimum Scattering Angle = 4.5 Degrees

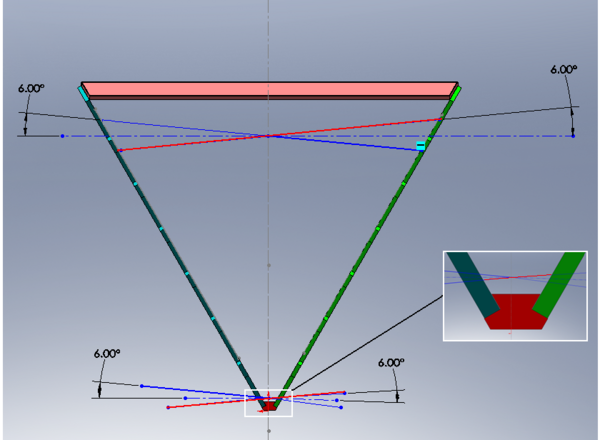

5. Wires are at 6 Degrees to the horizontal in each of its wire planes

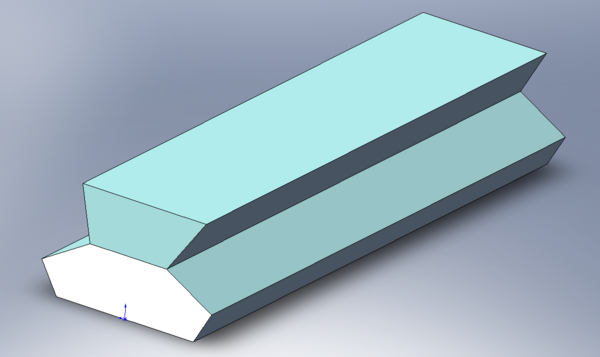

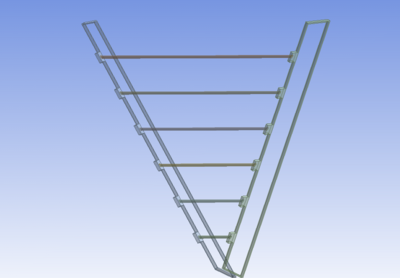

Assembly

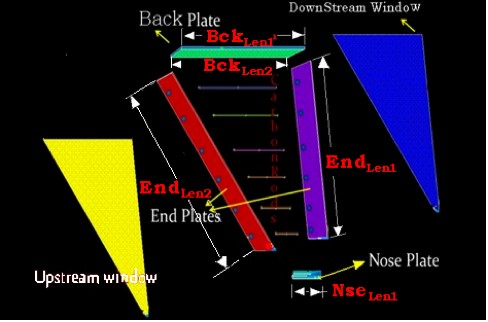

The Assembly of each sector in the region 3 drift chamber can be considered similar to each other. Each assembly can be divided into sub-assemblies like

1. Nose Plate

2. Left End Plate

3. Right End plate

4. Back plate

5. Backing Sheet

6. Carbon rods

7. Attachments: These are the external geometric parts of each sector, used for clamping and mounting each sector. so, they might change with the orientation of each sector

A detailed drawing of this assembly can be viewed at File:Assembly20 jun 1.pdf

Nose Plate

Nose plate is the plate where both the end plates are attached to it on either side

A detailed drawing of Nose plate can be viewed at File:Assembly20 jun 2.pdf

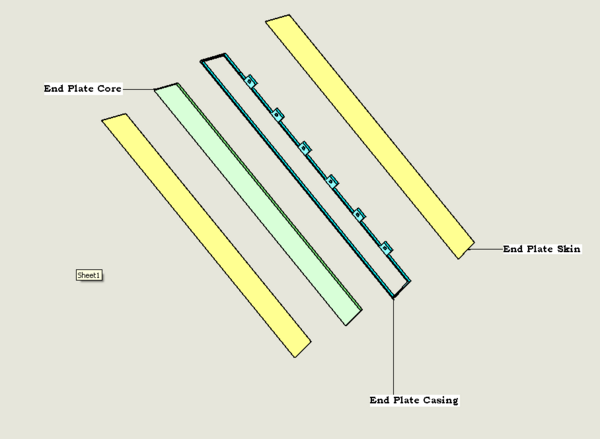

Left End Plate

Left end plate is the end plate to the left hand side if we are viewing from the target. Left end plate and the right end plate are same with parts and its dimensions. However, the hole locations differ between each other.

Each end plate sub assembly consists of 3 parts, namely

Left end plate Core - made of Polyurethane 600 px

Left end plate Skins - 2 No's- Made of stainless steel 600 px

End plate casing - Made of Aluminum.

They can be referenced with left and right to show each sub assembly.

A detailed drawing of Left end plate Core can be viewed at File:Assembly20 jun 4.pdf

A detailed drawing of Left end plate skin can be viewed at File:Assembly20 jun 5.pdf

Since end plate casing will not have holes for wires, the drawing for left end plate casing and right end plate casing will be the same.

A detailed drawing of Left end plate casing can be viewed at File:Assembly20 jun 6.pdf

Right end plate

Left end plate is the end plate to the left hand side if we are viewing from the target.

Right end plate Core - made of Polyurethane File:Assembly20 jun 7.png

Right end plate Skins - Made of stainless steel File:Assembly20 jun 8.png

They can be referenced with left and right to show each sub assembly.

A detailed drawing of right end plate Core can be viewed at File:Assembly20 jun 8.pdf

A detailed drawing of right end plate skin can be viewed at File:Assembly20 jun 9.pdf

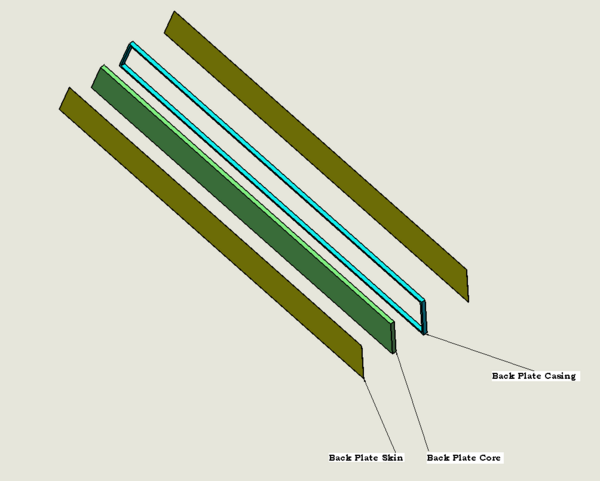

Back Plate

Back plate is the plate which connects the left end plate and right end plate on the top.

Back plate sub assembly consists of 3 parts, namely

Back plate Core - made of Polyurethane

Back plate Skins - 2 No's- Made of stainless steel

Back plate casing - Made of Aluminum

A detailed drawing of back plate Core can be viewed at File:Assembly20 jun 11.pdf

A detailed drawing of back plate skin can be viewed at File:Assembly20 jun 12.pdf

A detailed drawing of back plate casing can be viewed at File:Assembly20 jun 13.pdf

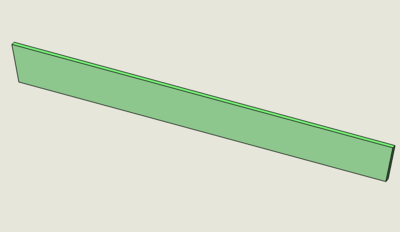

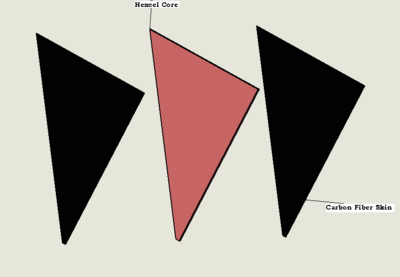

Backing Sheet

Backing sheet is the large sheet which is mounted on the downstream side of sector.

It consists of 2 parts, namely

Hexcel Core and Carbon fiber skins on either side

A detailed drawing of back plate Core can be viewed at File:Assembly20 jun 14.pdf

A detailed drawing of back plate skin can be viewed at File:Assembly20 jun 15.pdf

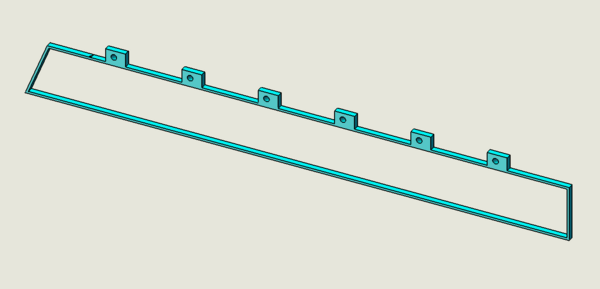

Carbon fiber rods

These rods are mounted on the upstream side of each sector, connecting the left end plate aluminum casing and right end plate aluminum casing..

There are 6 Carbon rods each of outer diameter of 50.8 mm and inner diameter of 48.26mm

A detailed drawing of carbon fiber rods can be viewed at File:Assembly20 jun 16.pdf