Difference between revisions of "201202 R1ProgressRep"

| Line 198: | Line 198: | ||

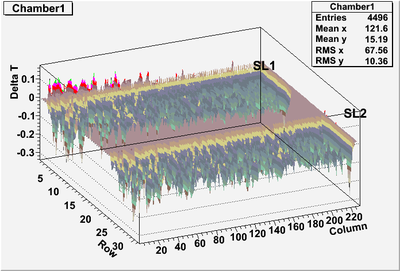

To construct the graph below it was assumed that the tension measurements have decrease by 7% since they were measured. | To construct the graph below it was assumed that the tension measurements have decrease by 7% since they were measured. | ||

| − | + | <math>\Delta T \equiv \frac{0.93 \times T_{\mbox{Measured}}}{T_{\mbox{calculated}}} -1</math> | |

[[File:R1C1_DeltaTloose_2-19-2012.png | 400 px]] | [[File:R1C1_DeltaTloose_2-19-2012.png | 400 px]] | ||

| + | |||

| + | SL1 lies between rows 1 and 10. | ||

| + | |||

| + | SL2 lies between row 20 and 30. | ||

Revision as of 23:44, 19 February 2012

2/2/12

Chamber is being rotated this morning to start potting on the next endplate. All plugs and standoffs have been glued on this endplate.

There were clearance issues as we were trying to position the chamber to pot the other endplate.

The magnet rail needed to be removed so that we could position the chamber properly.

Also, we are limited to how much we can rotate the chamber.

Camera settings give this image a yellow hue...sorry :P

Camera settings give this image a yellow hue...sorry :P

Because of this clearance issue, we couldn't even rotate the chamber 270°, but I don't even know if we will ever need to rotate the chamber this much.

We got around this by shifting the entire chamber/strongback/upper shaft forward several inches.

2/6/12

Potting has been completed.

Mylar window installation will begin tomorrow.

2/9/12

After some discussions it was decided that we need to re-measure the wire tensions and re-check wire integrity to confirm the chamber is ready for Mylar window installation.

The magnet will be re-installed.

Tested wire integrity on first 30 wires SL2

2/14/12

- Power supply current for magnet set to 50Amps DC

- Removed Drift Chamber

- re-positioned the rotating shaft to its original position

- Installed bolt 18 to prevent shaft from moving horizontally.

- Reinstalled magnet rail with drift chamber lying horizontally on the floor

- installed chamber back onto the A-frame

- reinstalled magnet

- hooked up power supply leads to begin tension measurements

Hampton Roads Article on ODUs R2 construction

http://hamptonroads.com/2012/02/device-built-odu-crack-natures-code-takes-ride

2/15/12

2/16/12

Tension calculation

Superlayer 2

Column 190 Row 7

- SL2-S1-Field (not trend file) Wire length = 151.76

- Trend File wire length = 145.44 (Spreadsheet indicates out of spec)

After further examination, we find that the wire lengths are correct. We were mistakenly comparing a SL1 wire length to a SL2 wire length. (2/17/12)

2/17/12

The following calculations were made using tension measurement data collected after wire stringing. An estimate of a 7% decrease over the entire chamber in tension errors was used to identify potential out of spec wires. The 'Total Wires out of Spec (7%)' is an over estimation. Further analysis will determine a more accurate percent decrease in tension to provide a more conservative count of potential out of spec wires.

Tension Measurement Summary

| SL1-Field Wires | |||||

| Tension Error Calculations | Number of Wires | ||||

| Column 2-45 (<-0.20) | 9 | ||||

| Column 46-90 (<-0.15) | 9 | ||||

| Column 91-227 (<-0.10)(7%) | 348 | ||||

| Column 91-227 (<-0.10)(3%) | 59 | ||||

| Column 2-227 (>0.15) | 0 | ||||

| Total Wires out of Spec (7%) | 366 | ||||

| Total Wires out of Spec (3% at 91-227) | 77 | ||||

| % Wires out of Spec (7%) | 23.2% | ||||

| % Wires out of Spec (3%) | 4.89% | ||||

| SL1-Sense Wires | |||||

| Tension Error Calculations | Number of Wires | ||||

| Column 3-75 (<-0.20) | 8 | ||||

| Column 76-150 (<-0.15) | 3 | ||||

| Column 151-227 (<-0.10)(7%) | 46 | ||||

| Column 151-227 (<-0.10)(3%) | 6 | ||||

| Column 2-227 (>0.15) | 0 | ||||

| Total Wires out of Spec (7%) | 57 | ||||

| Total Wires out of Spec (3% at 151-227) | 17 | ||||

| % Wires out of Spec (7%) | 8.49% | ||||

| % Wires out of Spec (3%) | 2.53% | ||||

| SL2-Field Wires | |||||

| Tension Error Calculations | Number of Wires | ||||

| Column 2-45 (<-0.20) | 5 | ||||

| Column 46-90 (<-0.15) | 13 | ||||

| Column 91-227 (<-0.10)(7%) | 231 | ||||

| Column 91-227 (<-0.10)(3%) | 70 | ||||

| Column 2-227 (>0.15) | 0 | ||||

| Total Wires out of Spec (7%) | 249 | ||||

| Total Wires out of Spec (3% at 91-227) | 88 | ||||

| % Wires out of Spec (7%) | 15.8% | ||||

| % Wires out of Spec (3%) | 5.59% | ||||

| SL2-Sense Wires | |||||

| Tension Error Calculations | Number of Wires | ||||

| Column 3-75 (<-0.20) | 6 | ||||

| Column 76-150 (<-0.15) | 11 | ||||

| Column 151-227 (<-0.10)(7%) | 30 | ||||

| Column 151-227 (<-0.10)(3%) | 7 | ||||

| Column 2-227 (>0.15) | 0 | ||||

| Total Wires out of Spec (7%) | 47 | ||||

| Total Wires out of Spec (3% at 151-227) | 24 | ||||

| % Wires out of Spec (7%) | 7.00% | ||||

| % Wires out of Spec (3%) | 3.58% | ||||

Chamber 1 Tension difference

To construct the graph below it was assumed that the tension measurements have decrease by 7% since they were measured.

SL1 lies between rows 1 and 10.

SL2 lies between row 20 and 30.