Two bricks x-pinch driver fabrication

Progress Reports

December 08, 2013

- The updated drawing of bricks with remeasured front plate's holes created (drawing #2013.1.001.0001)

December 09, 2013

- The list of possible manufacturing company for Brick's Housing (BH) parts production is established:

- Partner Steel Co, Inc, Pocatello;

- Valley Sheet Metal (VSM) Technologies, Idaho Falls;

- Primear Technology, Blackfoot;

- Northwest wire EDM, Spokane, WA;

- Nelson Metal Technology, Payette, ID;

- Water Jet Cutting, Albuquerque;

- All above companies have been contacted for quotes. Criteria were price and speed of production.

December 10, 2013

- Brick's Housing (BH) parts (steel/AL/PMMA sheets) drawings is approved by Spielman (drawings #2013.1.001.0002-0009)

December 11, 2013

- VSM Technologies: selected as manufactured company for BH parts (drawings #2013.1.001.0002-0009)

December 17, 2013

- BH parts arrived at IAC and inspected. Kevin is going to assemble and weld them all together.

December 18, 2013

- Cathode/anode drawings submitted to Spielman for approving (drawings #2013.1.001.0010-0017)

- PMMA_Output_Sheet/Charging_Isolating_Tube drawings submitted to Spielman for approving (drawings #2013.1.001.0018-0019)

- X-pinch driver assembly drawing with included cathode/anode submitted to Spielman for approving (drawing #2013.1.001.0020)

- PARKER's Viton O-rings V0769-60 2-246 (2 pcs), ID 4 1/2 and W 1/8", selected for vacuum seal inside the cathode/anode section.

December 19, 2013

- LESKER reduced 4-way cross (C-0800-275, $890) found as a candidate for vacuum chamber [1];

- LESKER reduced 4-way cross drawing downloaded and incorporated into SolidWorks (assembly file Lesker_C-800_275\C-0800-275_reassembled);

- LESKER reduced 4-way cross redesigned to match our x-pinch driver (drawing file Lesker_C-800_275\2013.1.001.0030);

December 20, 2013

- Some changes to parts have been done to accommodate LESKER redesigned cross:

- 1) for Al output plate, the inner cut increased from 4.5 diameter to 10" diameter to match the cross (drawing #2013.1.001.0008);

- 2) for anode can, the slot size increased from 0.4" to 0.5" to march x-pinch wires length (drawing #2013.1.001.0014);

- Reassembled LESCER cross drawing submitted to Spielman for approving (drawing LESKER C-0800-275_REASSEMBLED)

- X-pinch driver assembly drawing with included cathode/anode/cross submitted to Spielman for approving (drawing #2013.1.001.0021)

- LESCER cross and new assembly drawings is approved by Spielman:

December 30, 2013

- LESKER reduced 4-way cross (C-0800-275, $890) is ordered [2], [3]. Expected delivery id January 16, 2014. Comments: this one we will cut and reassemble later in the way we need. Just to remind, I plan two use one 8" flange for plate connection, one 8" flange for x-pinch access and vacuum pump connection, one 2 3/4 flange for x-ray diagnostics and one 2 3/4 flange for x-ray output.

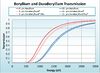

- for x-ray windows we can use Beryllium window (available from Moxtek in 1-1/3 and 2-1/8 CF flanges [4]).

For 2-1/8 CF flanges x-ray window, we will need Zero-Length Reducer Flange (from 2 3/4 to 2 1/8), like [5]

- can we use quartz window instead of beryllium? (we can probably borrow one from IAC stock);

- do we need RIGHT NOW x-ray window? A: no, we will need just glass viewport for x-pinch visual observation;

December 31, 2013

Other parts we need for vacuum chamber are:

- flanges:

- 8" fixed blank CF flange, Lesker part #F0800X000N, $125 [6]. Note: I would cut this flange in the middle to reduce the weight twice from 12 -> 6 lbs;

- 2 3/4" fixed bore 1.63" CF flange, Lesker part #F0275X175N, $15 [7]. Note: this flange will be used for x-ray diode's mounting;

- 2-3/4" CF flange viewport window. Note: this flange will be used for visual x-pinch observation. Later this flange can be replaced by x-ray window. Choose the cheapest (first) one:

- gaskets [11]:

- 1/4 Hard OFHC Copper Gasket for 2-3/4" CF flange, Lesker part #GA-0275, set of 10, $26.40;

- 1/4 Hard OFHC Copper Gasket for 8" CF flange, Lesker part #GA-0800, set of 10, $75.00.

- fasteners scroll down:

- 5/16—24 x 2-1/4" Bolt & Nut Set, Lesker part #HBS31224225, set of 25, $37.58 (for 8" flange up);

- 5/16—24 x 1-3/4" Bolt Kits, Lesker part #HBK31224175, set of 25, $30.60 (for 8" flange Al plate connection), (need 1" length);

- 1/4—28 x 1-3/8" Bolt & Nut Set, Lesker part #HBS25028138, set of 25, $29.38 (for 2-3/4" flanges);

- Total quote is xxx.xx plus shipping.

January 02, 2014

- Al output plate drawing #2013.1.001.0008 is updated to accommodate vacuum chamber's cross (11" cut changed to 8" and added slot cuts for small flanges);

- Reassembled Lesker cross drawing #2013.1.001.0030 is updated (file name changed and added some dimensions for clarity);

- Assembly drawing #2013.1.001.0021 is updated for clarity;

January 02, 2014

PMMA o-ring and groove design

- o-ring material we are needed:

- Viton (V1436-75, V1475-75, V1476-75);

- assumption made:

- viton = fluorocarbon;

- hardness we nee 70-80;

- o-ring size we are needed:

- nominal: ID=4-1/2, OD=4-3/4, W=1/8;

- actual: ID=4.484", W=0.139";

- Parker size number 2-246;

- o-ring we are needed:

- V1436-75 2-246;

- V1475-75 2-246;

- V1476-75 2-246;

- grove shape and size design:

- chapter 4.3, section IV - static o-ring sealing, Parker o-ring handbook.pdf:

- groove shape standard;

- ID=4.484", W=0.161", OD=4.806", Depth = 0.104", R=0.017", Finish = 16 RMS uinch;

- also see Eriks groove/o-ring calculator [12], pdf report File:03012014162515.pdf;

- assumption made:

- external pressure;

- ID(groove) = ID (actual o-ring size);

- o-ring deformation is about 25%;

- chapter 4.3, section IV - static o-ring sealing, Parker o-ring handbook.pdf:

- o-ring's grooves included into the PMMA drawing #2013.1.001.0018;

January 07, 2014

talked with R. Spielman:

- o-ring: the hardness of o-ring doesn't matter;

- gaskets:

- use Viton square gaskets for large flange instead of Cu, it could be used many times;

- cutting the large twice is OK;

- small flanges: using one blank and one veiwport is OK. Note: buy two blank (%15 each) and use viewport if available from IAV stock;

- vacuum chamber, anode, cathode drawings all are looking good;

parts we need to order extra for vacuum chamber:

- flanges:

- use Viton square o-ring to seal all flanges;

- fasteners, I will look at later;

January 10, 2014

talked with Kevin about vacuum chamber and anode/cathode:

- for vacuum chamber we need to order extra:

- 8" CF rotatable flange 6" pipe;

- 8" CF non-rotatable flange 6" pipe;

- 8" CF blank flange;

- Kevin recommended Duniway stockroom corp;

- order material (Grainger) and then we will do it at IAC;

- ask ParnerStill (Pocatello) about naterial, but they will probably ask what grade of brass we need;

- 8" flanges from MDC Vacuum have been ordered [16]:

January 13, 2014

x-pinch fabrication update

- vacuum chamber: all parts are ordered and after its arriving we start to fabricate the vacuum chamber;

- cathode/anode:

- should be approved? yes, and also need to include current monitor in anode cane drawing;

- identify and buy brass cuts; use naval/hard brass, should be easy to machined and inexpensive

- after vacuum chamber will be fabricated, update, if needed, drawings and fabricate anode/cathode parts;

- AL output plate (drawing 2013.0001.0008): need to modify;

- PMMA sheet output (drawing 2013.0001.0018): need to buy sheet and fabricate;

- charging isolating tube: need to buy rod and fabricate (how and who?)

- oil foamsm where to take?

- square viton o-ring: look at MDC Vacuum, or call them and ask for square Viton o=rinf for 8" flange

Found mistake in fabrication the Al output plate: the central whole is centered in all direction, but should not be. Need to make update of all drawings to reflect this fact;

- AL output plate drawing 2013.0001.0008 is updated to reflect real cut made in Al plate (done);

- Anode/cathode drawings need to be modified to reflect real cut made in Al plate (done):

- bricks has a freedom inside, mostly in horizontal directions. How we center cathode vs anode:

- make as reference plates the bottom and front of housing and update cathode plate drawing 2013.0001.0010 to center cathode vs anode;

- need some extra parts (tube ID=2" OD=2.5") for centering;

- where to include second current monitor?

- in anode can drawing 2013.0001.0010;

- make anode can thicker to have extra space for diagnostic mounting;

- Output PMMA plate need to be modified to reflect real cut made in Al plate (done);

January 15, 2014

Found that housing plastic sheets we ordered do not have precise thikness we asked and wanted:

- They are really 0.45-0.49" and 0.23-0.235" instead of 1/2 and 1/4 as we expected to be;

- Most likely that plastic supply companies switched to metrics (mm) standard. But they still specify thickness in inches, but real thickness is less, like 0.47" instead of 0.5". Some company specify this fact [19];

- Found company which probably still supply plastic in inches we need [20];

Ordered plastic sheets (housing side's isolating and housing output isolating) and HDPE rod:

- Professional Plastics.com [21];

- Order summary [22];

- Hopefully they will have precisely the same thickness and diameter as we want, but not the different thickness as happened before;

- Charging Isolating Tube have been modified to accommodate new two lines design (done);

January 16, 2014

- Anode/cathode brass cuts have been ordered:

- we need naval brass, like C464, or any hard brass. Should have a property of good machining and be also cheap;

- sheet 7" x 9" x 0.25";

- rod 1-1/8"(diam) x 1" (long);

- rod 2-1/8"(diam) x 10" (long);

- rod 4-1/2"(diam) x 10" (long);

- call Pocatello Partner Steel 233-2371;

- GOOGLE: BRASS SHEET -> Online Metals [23], Metals Depot, Metal Mart, etc.;

- Assembly drawings need to be modified to reflect all recent updates done (done);

January 22, 2014

- Arrived Lesker Reducing Cross;

- Arrived PMMA sheets

- Arrived brass metals

- Arrived RG-223 cable

- Created new drawing for Vacuum Chamber 2014.1.001.0030-33 (new design using cross and 2 flanges) (done);

- Created new drawing for x-pinch driver assembly 2014.1.001.0040 (to accommodate new vacuum chamber drawing) (done);

- Created new isolated sheets drawing 2013.1.001.0002-3 (to accommodate real life: sheet thickness, sheet material, BH enclosure interior dimensions) (done);

January 28, 2014

Fasteners we need (McMaster-Carr):

- for Al_plate/BH_Flanges assembly:

- Medium-Strength Zinc-Plated Steel Cap Screw - Grade 5 3/8"-16 Fully Threaded, 1-1/4" Long ($11.85 per pack of 50) [24]

- Plain Grade 5 Steel Hex Nut 3/8"-16 Thread Size, 9/16" Width, 21/64" Height ($5.76 per pack of 100) [25]

- 18-8 Stainless Steel General Purpose Flat Washer 3/8" Screw Size, 7/8" OD, .04"-.06" Thick ($5.64 per pack of 100) [26]

- for 8" flanges:

- Alloy Steel 12-Point Flange Head Cap Screw 5/16"-24 Thread, 1" Length, Fully Threaded ($7.43 per pack of 25) [27]

- Alloy Steel 12-Point Flange Head Cap Screw 5/16"-24 Thread, 1-1/4" Length, Fully Threaded ($8.51 per pack of 25) [28]

- Alloy Steel 12-Point Flange Head Cap Screw 5/16"-24 Thread, 2" Length ($11.20 per pack of 25) [29]

- Zinc-Plated Grade 5 Steel Hex Nut 5/16"-24 Thread Size, 1/2" Width, 17/64" Height ($4.89 per pack of 100) [30]

- 18-8 Stainless Steel General Purpose Flat Washer 5/16" Screw Size, 3/4" OD, .04"-.06" Thick ($5.10 per pack of 100) [31]

- for 2-3/4 flanges:

- Alloy Steel 12-Point Flange Head Cap Screw 1/4"-28 Thread, 1-1/2" Length ($13.61 per pack of 50) [32]

- Zinc-Plated Grade 5 Steel Hex Nut 1/4"-28 Thread Size, 7/16" Width, 7/32" Height ($3.78 per pack of 100) [33]

- 18-8 Stainless Steel General Purpose Flat Washer 1/4" Screw Size, 5/8" OD, .04"-.06" Thick ($3.37 per pack of 100) [34]

- for anode/cathode assembly:

- 18-8 Stainless Steel Flanged Button-Head Socket Cap Screw 10-32 Thread, 3/8" Length ($9.25 per pack of 25) [35]

- Type 316 Stainless Steel Flat-Head Socket Cap Screw 10-32 Thread, 3/4" Long ($3.79 per pack of 10) [36]

- Type 316 Stainless Steel Flat-Head Socket Cap Screw 8-32 Thread, 3/8" Long ($2.91 per pack of 10) [37]

- Total quote from McMaster-Carr $97 (without last item in quote) [38]

- special brass screw for anode/cathode

- Total quote from McMaster-Carr $43.33 [42]

January 29, 2014

We can order only order from Fastener or Grainger

Fastenal:

- 3/8"-16 x 1-1/2" Zinc Finish ASTM A307A Hex Bolt [43] (need 24 for BH)

- 5/16"-24 x 1" Zinc Finish SAE J429 Grade 5 Hex Cap Screw [44] (need 18 for VC bottom flange)

- 5/16"-24 x 1-1/4" Zinc Finish SAE J429 Grade 5 Hex Cap Screw [45] (need 18 for VC bottom flange, initial test)

- 5/16"-24 x 2" Zinc Finish SAE J429 Grade 5 Hex Cap Screw [46] (need 20 for VC top flange)

- 1/4"-28 x 1-1/2" Zinc Finish SAE J429 Grade 5 Hex Cap Screw [47] (need 12 for VC side flanges)

- 3/8"-16 Zinc Finish Grade A Finished Hex Nut [48] (need 24 for BH)

- 5/16"-24 Zinc Finish Grade 5 Finished Hex Nut [49] (need 20 for VC top flange)

- 1/4"-28 Zinc Finish Grade 5 Finished Hex Nut [50] (need 12 for VC side flanges)

- #10-32 x 3/8" Zinc Finish Alloy Steel Socket Cap Screw [51] (need 8 for anode can)

- #10-32 x 7/16" 18-8 Stainless Steel Socket Cap Screw [52] (need 8 for anode can)

- #10-32 x 3/4" Zinc Finish Flat Socket Cap Screw [53] (need 4 for cathode plate)

- #8-32 x 3/8" Zinc Finish Flat Socket Cap Screw [54] (need 8 for cathode/anode tips)

- 3/8" Zinc Finish SAE Flat Washer [55] (need 48 for BH)

- 5/16" 18-8 Stainless Steel Small OD Flat Washer [56] (need 20 for VC bottom flange)

- 5/16" Zinc Finish SAE Flat Washer [57] ((need 80 for VC bottom/top flange))

- 1/4" Zinc Finish SAE Flat Washer [58] (need 24 for VC side flanges)

- #10 18-8 Stainless Steel Large OD Thick Flat Washer [59] (need 8 for anode can)

- #10 Brass Small OD Flat Washer [60] (need 8 for anode can)

- Total quote from Fastenal $82.53 [61]

Brief Summary/To Do List

Rick Spielman's x-pinch task list [62]

- Can we use cross instead of cube? (A: Cross - not, but reduced cross - yes);

- Do we need to use Cu gasket to seal CF flange? If so, we need a lot of them for every shot. (A: no, we will use Viton square o-ring);

BRICK HOUSING (DONE)

- design (done);

- fabrication (done);

BRICK HOUSING'S ISOLATION (DONE)

- design (done);

- fabrication (done);

OUTPUT ISOLATING PLATE (DONE)

- design (done);

- fabrication (done);

ISOLATING O-RINGS (DONE)

- Identify o-rings (done);

- Design o-ring groove (done);

- Include o-ring's grooves into the PMMA drawing #2013.1.001.0018 (done);

- Buy Viton o-rings (done);

- Fabricate grooves inside PMMA output plate, drawing #2013.1.001.0018 (done);

VACUUM CHAMBER (DONE)

- Design x-pinch vacuum chamber (done);

- Include Al plate's taped holes in drawing #2013.1.001.0008 (done);

- Discuss reassembling possibilities with Kevin (done);

- Buy all parts for x-pinch vacuum chamber:

- Buy LESKER 8"/2-3/4" reducing cross (done);

- Buy 8" flanges (done);

- locate at IAC 2-3/4 flange and viewport (done);

- buy Viton square o-rings for all flange sealing (done);

- Fabricate vacuum chamber at IAC (done);

CATHODE/ANODE/SPACER (DONE);

- Design x-pinch cathode/anode (done except of B-dot accommodation);

- Discuss possibilities of fabrication in IAC with Kevin (done);

- Order brass cuts (done);

- Fabricate anode/cathode/spacer parts, drawings #2013.1.001.0010-0018 (in process);

- assemble anode/cathode (done);

CHARGING LINE

- identify parts we need (done);

- locate +100 kV power supply (done);

- buy conductive o-ring (done);

- buy HDPE tube (done);

- buy Al hemispheres (done);

- weld Al hemisphres (done);

- assemble charging line;

TRIGGER LINE

- locate Trigger (done);

- locate power supply for trigger;

- locate pulser for trigger (done);

- assemble trigger line;

DIAGNOSTIC: ROGOWSKI COIL (DONE)

- Read and discuss Rick's notes and paper (done);

- design RogoWskii (done see Rick's notes);

- include Rogowskii in drawing (done);

- buy RG-58 or RG-223 (double isolating) (done);

- sticky Kapton tape (couple of mils thick with sticky on one side, 2" x ~20 yards) [63][64] (done);

- sticky copper tape (2" x ~20 yards) [65][66][67] (done);

- build Rogowskii (done);

DIAGNOSTIC: B-DOT

- Read Rick's paper about B-Dot;

- design B-dot;

- build B-dot

FINAL TO DO TOMORROW

- x-pinch funding? extension?

- NWAPS, Seattle?

- NWAPS, April 10 due student grant

- internal report: mechanical design

- locate +7kV for PT-55

- ground stick locate/fabricate

- check the gap with new plate

- Rogowskii: make one more

- call Katsilometes, Whitman&12th, Bonneville etc.

Total Cost So Far

- Spielman's bricks (priceless);

- BH: steel sheets, flanges and covers, $910 [68];

- BH: PMMA, $239 [69];

- BH: extra plastic, HDPE and Acrylic, sheet and rod, $139.67 [70];

- BH: extra plastic, HDPE (36" x 13" x 0.5") replacement for Khalid, $54.95 (including $24.95 shipping)

- BH: extra Acrylic output sheet (12" x 11" x 1"), redoing, $32.02 plus next day shipping $87.39 [71]

- Vacuum Chamber: Lesker reducing 4-way, 8" OD to 2-3/4 OD cross, $890 plus shipping [72], [73];

- Vacuum Chamber: Flanges 8" (blank and 6" ID), $393 plus shipping [74];

- Vacuum Chamber: machining, Quality Concepts Precision Machining, $690

- Anode/Cathode: Brass, $463.37 (with shipping) [75];

- Anode/Cathode: 3/4 Brass bolts for cathode, 25.93 plus shipping [76]

- Rogowski: RG-223 200 Ft, $137 (including $12 shipping) [77];

- Rogowski: Kaplan tape, $14.61 [78]

- Charging Line: Simolex conductive o-ring material, 25 Ft, $268.5 (including shipping) [79][80]

- Charging Line: Al hemispheres, $192 (including shipment) [81];

- Charging Line: Boedeker HDPE thick tube;

- Charging Line: HDPE ID=1/2" OD=3/8" tubing, $20.23 [82];

- Charging Line: Al hemispheres welding, $110.50

- Sealing: Viton o-ring for output isolating plate, $16.89 [83];

- Sealing: Silicone o-ring for output isolating plate, $16.29 [84];

- Sealing: Viton square o-ring for 8" and 2-3/4" flanges, $75 [85];

- Load: 1-5 mm Nichrome wires, $40.70 [86][87]

- Load: 1 Ohm 12 kJ 20 kV Resistors, $60.80 plus shipping [88]

- Fasteners, Fastenal $37.67 [89]

- Fasteners, McMaster $43.33 [90]

- Ipotec Foam, $360.87 (min order 3 pcs $120.29/piece) [91];

- Fingerstocks, $50.16 plus shipping [92]

- Glassman High voltage power supply's output cable, $275 plus $25 shipping [93]

- Total: $5670.39