CLAS12 R1

Time line

| Start Date | Description |

| Chamber Stringer Design | |

| Chamber StringerConstruction | |

| Chamber Stringerr Delivery | |

| 5/8/09 | Clean Room Setup |

| 6/8/09 | Chamber Parts delivered, wires, endplates, backplate, nose plate, feedthroughs. mylar window, |

| 6/8/09 | Wire tension apparatus in place |

ISU Clean Room Facility

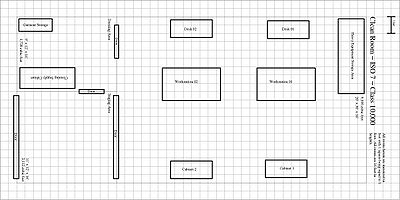

Below is a preliminary schematic of the floor design of ISU's clean room that will be built at the Pocatello airport.

The dimensions of the clean room itself will be:

16' high 30' deep 20' wide

The doors into and out of the different areas will be 9'8" high in order to help facilitate the transport of equipment into and out of the different areas of the clean room.

The desks in the clean room will act as a table top area to place tools and other equipment currently in use during the construction of the wire chambers. Also, they will serve as a place to perform any calculations or other miscellaneous work that may come up while construction is ongoing.

The cabinets on the other side of the room will be a permanent storage area for all tools and equipment not currently in use at the two work stations.

The path in between the workstations and the cabinets will be kept clear of all obstructions in order facilitate the movement of equipment into and out of the room as needed.

The two workstations will be where the wire chambers are constructed. The workstations will have a standing/sitting apparatus built around them in order to help those who are stringing the wire chambers to have better access to the chambers from above. Schematics for these will be uploaded as they are designed.

The heavy equipment storage area will be where all the heavier equipment (i.e. dollies, fabrication materials, etc...) that will not fit, or does not need to be stored in the individual work station cabinets will be kept.

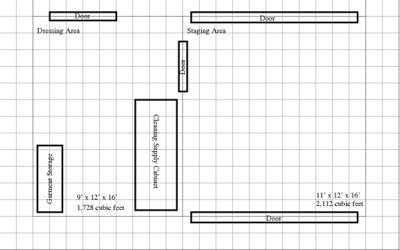

Staging & Dressing Area

Attached to the clean room, and also kept in a class 10,000 environment, will be the staging area that will be used to transport the wire chambers and other materials into and out of the clean room environment, and will also help facilitate entrance into the dressing and prep area that people will use before entering the clean room itself.

Staging Area Dressing Area 16' high 16' high 12' deep 12' deep 11' wide 09' wide

The dressing area will be where the cleaning supply cabinet will be kept. This is because when cleaning the clean room one will start at the back and work their way forward. This is to prevent cross contamination in the cleaning process from a person treading upon previously cleaned area.

Inside the cleaning supply cabinet will be where the cleaning chemicals and other supplies are stored for cleaning of the clean room. A list of supplies and cleaning schedule will be uploaded in the near future.

Ceiling Support, HEPA Filters, & Lighting

Another schematic that will be uploaded in the future will be an aerial view of the clean room that will include light fixtures, hepa filters and fans, and other structural support. This will be uploaded once the proper air volume flows per hour have been calculated, and the types of hepa filters have been determined.

ODU's Clean Room

ODU's current clean room size:

high deep wide

CLAS 10,00 clean rooms

Environmental control needed

Temperature control constraint is

Humidity control: 55 % or less

Cleaning Procedures

R1 Construction preparations

Discussion items

1.) Budget

- JLab to ISU travel for JLab personnel to inspect operations

- shipping container for R1 chambers

2.) Clean room

cost =

assume we copy the ODU clean room

Using IAC conference room space, need to remove carpet and paint floor.

3.) hiring timeline

9/08 NSF proposal submission

4.) stringing platform and DC stringing support arm

5.) Manpower

6.) MOU to support post doc request or faculty release time

7.) Stringing equipment

a.) crimping tool

b.) glue

c.) wire or feedthroughs?

d.) wire tension measurement (PC, Magnets, associated electronics

A few pictures ff the R1 fullo size proto type from my JLab visit on 9/16/07. It is about 6 feet tall. CLAS12_R1_Prototype_9-16-07

The air actuated crimping tool: