Difference between revisions of "Detector Description"

| Line 3: | Line 3: | ||

==Clean Environment== | ==Clean Environment== | ||

| − | Gaseous detectors, like most detectors, are constructed in environments that minimize the presence of contaminants. Most of the methods for detector construction and maintaining demand a clean environment. Generally, clean environments are classified into classes depending on the size and the number of existing particulates in the room, each class maintains its environment by filtering the air that enters the room, by keeping air circulation | + | Gaseous detectors, like most detectors, are constructed in environments that minimize the presence of contaminants. Most of the methods for detector construction and maintaining demand a clean environment. Generally, clean environments are classified into classes depending on the size and the number of existing particulates in the room, each class maintains its environment by filtering the air that enters the room, by keeping air circulation in a specific rate, and using barriers that isolate the room the surrounding environment. Clean rooms have restrictions on the type of materials for the equipment and furniture, and have special instructions for the workers who can carry contaminants, so the workers have to use gloves, hats, pants and gowns that are designed for this purpose. Laminar hoods is another method to get a clean environment, they are easy to maintain, and usually provide enough space for building and maintaining small size detectors. |

==Detector Parts== | ==Detector Parts== | ||

Revision as of 07:49, 22 October 2013

GEM Detector Design

Clean Environment

Gaseous detectors, like most detectors, are constructed in environments that minimize the presence of contaminants. Most of the methods for detector construction and maintaining demand a clean environment. Generally, clean environments are classified into classes depending on the size and the number of existing particulates in the room, each class maintains its environment by filtering the air that enters the room, by keeping air circulation in a specific rate, and using barriers that isolate the room the surrounding environment. Clean rooms have restrictions on the type of materials for the equipment and furniture, and have special instructions for the workers who can carry contaminants, so the workers have to use gloves, hats, pants and gowns that are designed for this purpose. Laminar hoods is another method to get a clean environment, they are easy to maintain, and usually provide enough space for building and maintaining small size detectors.

Detector Parts

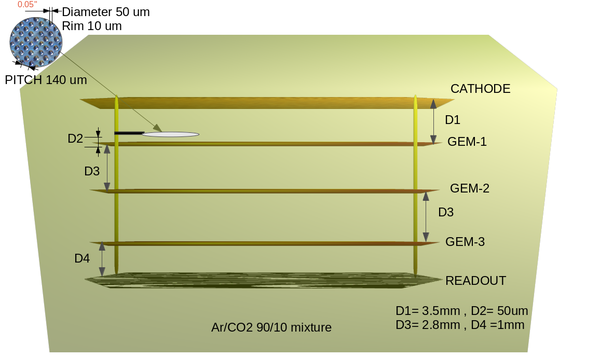

The triple GEM based neutron detector consists of :

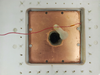

1- A cathode; a square copper plate has a dimension of 10x10cm and has a distance of 1.2 cm from the top of the fist GEM card. The cathode design allows to raise the potential on its surface up to 5 kV (in air) without any discharge effect.

2- GEM cards; the detector has three GEM cards in square plastic frames, they have dimension of 10x10cm and are placed parallel to the cathode as shown in the figure below.

Insert drawing with dimensions so someone can build a copy of your detector.

Each GEM preamplifier is made of a copper clad kipton plate of a thickness 50 um and an area of 10x10cm, It has holes with a diameter of 50 um and 10 um rim which are chemically etched in an equilateral triangular pattern with 140 um pitch distance.

4- A sealed chamber; All the previous components exist in a chamber that consists of two ertalyte plastic sheets , they are bolted together by a number of M3 plastic screws located around the detector window to form a well closed cavity around the GEM cards away from the surrounding atmosphere. The purpose of sealant is to insulate the chamber's gas from the surrounding atmosphere gas components. Also, the chamber has a square window of kipton of dimension of 13x13cm.

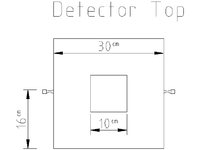

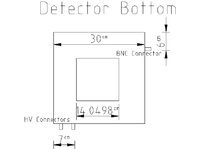

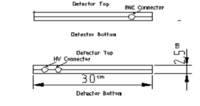

The figures below show top, bottom and side view of the detector design.

High voltage divider

GEM preamplifiers are connected with high voltage divider circuit. as shown in the figure below:

The ciruit provides the cathode with the highest voltage to drift most of the electrons primarily produced by ionization, then gradually the voltage decreases to have the least value on the bottom side of the third GEM card, which will help to guide all the electrons to the grounded readout plate.

Modifying the GEM detector as neutron sensitive detector

The GEM original design is modified to convert it to a neutron sensitive detector. One of changes is in the cathode design, it has a circular coating of U-233 with a diameter of 3 cm and 40-50 um thickness. Also the distance of the cathode from the first GEM becomes 8 mm instead of 3.5 mm. The kepton window's height increased to 2.5 mm, it helps to avoid any direct contact with the cathode when it is located to the new height. The figures below show the modified detector design. An FR4 shutter covers the coating area, if the shutter is close, it will stop the fission fragment ionization, when it is open, the ionization of the fission fragments will be cuase a signal that will be collected by the detector's trigout. The detector trigout is connected to a high pass filter to decrease the level of the detected noise as mentioned in details in the next section.

Go Back [1]