Difference between revisions of "Old CLAS12"

(Created page with " CLAS12_R1") |

|||

| Line 1: | Line 1: | ||

| + | |||

| + | |||

| + | [[File:04062012_TwoChambersInCleanRoom.png| 100 px]] | ||

| + | |||

| + | [[File:A10272011_CLAS12R1C1_Wires.jpg | 100 px]][[File:B10272011_CLAS12R1C1_Wires.jpg | 100 px]] | ||

| + | |||

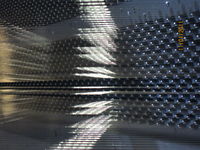

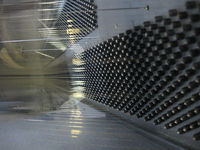

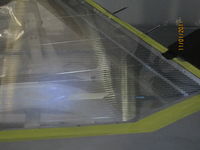

| + | The Field wires look like Idaho icicles when you turn off the lights to the clean room and shine a light through the entrance window | ||

| + | |||

| + | [[File:A11012011_CLAS12R1C1_Wires.jpg | 200 px]][[File:B11012011_CLAS12R1C1_Wires.jpg | 200 px]][[File:C11012011_CLAS12R1C1_Wires.jpg | 200 px]][[File:D11012011_CLAS12R1C1_Wires.jpg | 200 px]][[File:E11012011_CLAS12R1C1_Wires.jpg | 200 px]] | ||

| + | |||

| + | |||

| + | =ISU Clean Room Facility= | ||

| + | |||

| + | |||

| + | ;The chamber's longest wire should be lifted 4 ft off the floor. | ||

| + | |||

| + | ;Need a hand rail system so people don't fall off the ledge because they mistake the clean room wall for a solid structure. | ||

| + | |||

| + | [[File:BasementRenovationDrawing_6-16-10.pdf]] | ||

| + | |||

| + | [[File:BasementRenovationDrawing_6-28-10.pdf]] Changes to machine shop door | ||

| + | |||

| + | [[File:BasementRenovationDrawing_7-26-10.pdf]] Maybe the Final design with 8' hallways and 8' doors to the clean room | ||

| + | |||

| + | |||

| + | [[Media:Series575_CleanRoom_InstallManual.pdf]] | ||

| + | |||

| + | Ed cash : 242-8192 (manages electricians, call to be sure work order is in place for ) | ||

| + | |||

| + | ==CLAS 10,000== | ||

| + | Definition | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! rowspan="2" | Class | ||

| + | | colspan="6" align="center" | '''maximum particles/m³''' | ||

| + | ! rowspan="2" | FED STD 209E<br>equivalent | ||

| + | |- | ||

| + | ! ≥0.1 µm | ||

| + | ! ≥0.2 µm | ||

| + | ! ≥0.3 µm | ||

| + | ! ≥0.5 µm | ||

| + | ! ≥1 µm | ||

| + | ! ≥5 µm | ||

| + | |- | ||

| + | ! ISO 7 | ||

| + | | align="right" | | ||

| + | | align="right" | | ||

| + | | align="right" | | ||

| + | | align="right" | 352,000 | ||

| + | | align="right" | 83,200 | ||

| + | | align="right" | 2,930 | ||

| + | | align="center"| Class 10,000 | ||

| + | |- | ||

| + | ! ISO 9 | ||

| + | | align="right" | | ||

| + | | align="right" | | ||

| + | | align="right" | | ||

| + | | align="right" | 35,200,000 | ||

| + | | align="right" | 8,320,000 | ||

| + | | align="right" | 293,000 | ||

| + | | align="center"| Room air | ||

| + | |} | ||

| + | |||

| + | |||

| + | = JLab job posting for lead stringer= | ||

| + | |||

| + | add should be available at | ||

| + | |||

| + | https://isujobs.net/applicants/jsp/shared/Welcome_css.jsp | ||

| + | |||

| + | CLAS Wire Chamber Technician | ||

| + | Requisition Number 10534 | ||

| + | Job Category Technician/Drafter | ||

| + | Percentage of Travel No Travel | ||

| + | Job Responsibilities (TERM POSITION ENDING TWO YEARS FROM HIRE DATE) | ||

| + | |||

| + | DATE POSTED: FEBRUARY 11, 2010 | ||

| + | |||

| + | SALARY RANGE: $45,500 - $61,900 (TD II) | ||

| + | |||

| + | DUTIES: | ||

| + | Technician will be responsible for the fabrication of very large and very precise particle detection units called "wire chambers" in support of the CLAS 12 GEV project. These "wire chambers" will be built in a clean room by teams. Incumbent is expected to lead these fabrication teams. Specifically, individual will be responsible for leading a team in building these detectors and maintaining strict quality controls. Will be required to learn all aspects of detector fabrication, stringing and testing. Will fabricate and string the detectors maintaining high precision and quality. Will receive, clean and inspect parts for compliance with technical specifications. | ||

| + | Experience/Education Required MINIMUM QUALIFICATIONS: | ||

| + | Associates Degree plus 3 years of applicable experience or equivalent combination of education and relevant experience. Knowledge of basic electricity and/or electronics required. Knowledge and experience in the proper use of hand and power tools as well as ability to follow written procedures in operating and technical manuals also required. Basic computer skills such as Excel and/or CAD experience is a plus. Ability to work in a team environment. A background in quality control as well as experience supervising and motivating others in a team setting preferred. | ||

| + | |||

| + | Physical Requirements: | ||

| + | - Pass all medical requirements for the following qualifications: Rad Worker, ODH, Crane Operator, Forklift Operator, Aerial Platform Operator, etc. | ||

| + | - Cannot have a fear of heights or confined spaces. | ||

| + | - Must be able to climb stairs, ladders, vertical escape ladders and work in close quarters with others. | ||

| + | - Steady hands and eyes for delicate close-up work. | ||

| + | |||

| + | |||

| + | During interview have them try to crimp a wire. | ||

| + | |||

| + | |||

| + | Master rigger, to manipulate the chamber onto the stringing platform. | ||

| + | |||

| + | Master rigger class at JLab on November 2-4, 2010. Overhead training class pre-req. contact kelley | ||

| + | |||

| + | Overhead crane class, | ||

| + | |||

| + | |||

| + | [[TimeCLAS12R1_LeadStringer2]] | ||

[[CLAS12_R1]] | [[CLAS12_R1]] | ||

Revision as of 17:33, 1 March 2013

The Field wires look like Idaho icicles when you turn off the lights to the clean room and shine a light through the entrance window

ISU Clean Room Facility

- The chamber's longest wire should be lifted 4 ft off the floor.

- Need a hand rail system so people don't fall off the ledge because they mistake the clean room wall for a solid structure.

File:BasementRenovationDrawing 6-16-10.pdf

File:BasementRenovationDrawing 6-28-10.pdf Changes to machine shop door

File:BasementRenovationDrawing 7-26-10.pdf Maybe the Final design with 8' hallways and 8' doors to the clean room

Media:Series575_CleanRoom_InstallManual.pdf

Ed cash : 242-8192 (manages electricians, call to be sure work order is in place for )

CLAS 10,000

Definition

| Class | maximum particles/m³ | FED STD 209E equivalent | |||||

|---|---|---|---|---|---|---|---|

| ≥0.1 µm | ≥0.2 µm | ≥0.3 µm | ≥0.5 µm | ≥1 µm | ≥5 µm | ||

| ISO 7 | 352,000 | 83,200 | 2,930 | Class 10,000 | |||

| ISO 9 | 35,200,000 | 8,320,000 | 293,000 | Room air | |||

JLab job posting for lead stringer

add should be available at

https://isujobs.net/applicants/jsp/shared/Welcome_css.jsp

CLAS Wire Chamber Technician

Requisition Number 10534 Job Category Technician/Drafter Percentage of Travel No Travel Job Responsibilities (TERM POSITION ENDING TWO YEARS FROM HIRE DATE)

DATE POSTED: FEBRUARY 11, 2010

SALARY RANGE: $45,500 - $61,900 (TD II)

DUTIES: Technician will be responsible for the fabrication of very large and very precise particle detection units called "wire chambers" in support of the CLAS 12 GEV project. These "wire chambers" will be built in a clean room by teams. Incumbent is expected to lead these fabrication teams. Specifically, individual will be responsible for leading a team in building these detectors and maintaining strict quality controls. Will be required to learn all aspects of detector fabrication, stringing and testing. Will fabricate and string the detectors maintaining high precision and quality. Will receive, clean and inspect parts for compliance with technical specifications.

Experience/Education Required MINIMUM QUALIFICATIONS:

Associates Degree plus 3 years of applicable experience or equivalent combination of education and relevant experience. Knowledge of basic electricity and/or electronics required. Knowledge and experience in the proper use of hand and power tools as well as ability to follow written procedures in operating and technical manuals also required. Basic computer skills such as Excel and/or CAD experience is a plus. Ability to work in a team environment. A background in quality control as well as experience supervising and motivating others in a team setting preferred.

Physical Requirements: - Pass all medical requirements for the following qualifications: Rad Worker, ODH, Crane Operator, Forklift Operator, Aerial Platform Operator, etc. - Cannot have a fear of heights or confined spaces. - Must be able to climb stairs, ladders, vertical escape ladders and work in close quarters with others. - Steady hands and eyes for delicate close-up work.

During interview have them try to crimp a wire.

Master rigger, to manipulate the chamber onto the stringing platform.

Master rigger class at JLab on November 2-4, 2010. Overhead training class pre-req. contact kelley

Overhead crane class,