Difference between revisions of "Qweak Installation"

| Line 18: | Line 18: | ||

|- | |- | ||

|5/12/10 || || Survey Region 1 Chamber | |5/12/10 || || Survey Region 1 Chamber | ||

| + | |- | ||

| + | |5/13/10 || || Install Region 1 Readout electronics | ||

|- | |- | ||

|5/25/10 || || Qweak Commission | |5/25/10 || || Qweak Commission | ||

Revision as of 15:20, 19 April 2010

Information for installing the R1 chambers into Hall C

Installation Dates

Qweak Install Schedule in DOCDB

| Date | Milestone | |

| Planned (11/08) | Completed | |

| 11/25/09 | Qweak Install begins with Qtor | |

| 5/3/10 | Install Rotator Back Assembly | |

| 5/10/10 | install Region 1 Chamber | |

| 5/12/10 | Survey Region 1 Chamber | |

| 5/13/10 | Install Region 1 Readout electronics | |

| 5/25/10 | Qweak Commission | |

| 10/29/10 | Qweak Run 1 | |

| 4/11/11 | Qweak Run 2 | |

Definitions

- Survey tolorance

- The accuracy in the absolute location of an object

- Alignment Tolerance

- The accuracy of an object relative some other known object.

- "Would like to"

- desired alignment accuracy

- "Must have"

- Required alignment accuracy

- "Known to"

- desired survey accuracy

Tolorances

The charge collector strips are less than 0.4 mm wide. The concentric strips can give you a direct measurement of the electron scattering angle if they are properly alignment with the beam line.

The numbers below are just a Guess with no justification from a simulation or hand calculation.

Tolorance for GEM relative to the PRIMARY COLLIMATOR (2nd collimator)

Survey can pretend to do 50 micron resolution 200 micron resolution is no problem.

Survey marker tooling balls need 1/4 inch rods to mount prisms on. Should have at least 3, 1/4 holes on detector.

| Coordinate | "Would like to" | "Must have" | Known to |

| (mm) | (mm) | (mm) | |

| X | 0.05 | 0.2 | 0.2 |

| Y | 0.05 | 0.2 | 0.2 |

| Z | 1 | 10 | 1 |

| Yaw(about Y) | |||

| Pitch (about X) | |||

| Roll(about Z) |

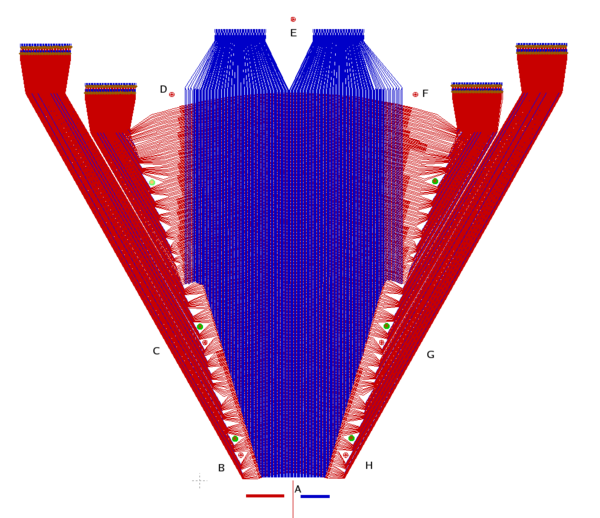

Survey marker locations

The coordinates given below are with respect to an arbitrary reference point identified by the cross hairs just below the label "B".

| Point | Design (x, y)(mm) | Hall-C (x', y') (mm) |

| A | 5.025; 60 | 7; 0 |

| B | 16.4858; 26.485 | 18.45658; -33.515 |

| C | 88.497; 3.492 | 90.477; -56.508 |

| D | 246.999; -18 | 248.979; -78 |

| E | 295.005; 60 | 296.985; 0 |

| F | 246.991; 138 | 248.971; 78 |

| G | 88.500; 116.493 | 90.48; 56.493 |

| H | 16.493; 93.488 | 18.473; 33.488 |

Chamber Gases

Region II and III wil use gas mixture:

| % Volume | Gas |

| 88 | Argon |

| 10 | CO2 |

| 2 | Methane |

Cables

GEM detectors : 4 SHV cables, 4 ribbon cables, 2 BNC trig out cables, 2 gas in lines, 2 gas out lines, 2 scan in lemos, 2 scan out lemos, 2 RJ45 cables.

Rotator: 120 Volt for controller, RS232 serial cable between LabView computer and controller?

JLAB supplies

- 4 SHV cables from GEM Rotator to Counting House (unless remote control via CAENET then SHV goes to location of CEAN 4 channel HV)

- 4 BNC Coax cables from GEM detector to Alena's scintillator coincidence NIM modules located near quartz detector (2 GEM trig out signals into LOGIC module 2 signals from logic module to VFAT to latch data)

- 2 BNC coax from rotator to counting house

- 4 120 Volt power lines to dog house (power GUMstick, VME crate, maybe NIM for LVDS signal creation)

- 2 120 Volt power lines to GEM rotator ( do we still needs these?)

- cable from G0 32 MHz clock to V1495 in the dog house

- 2 lemo cables from doghouse to rotator (CLK for VFATs)

- 2 gas inlet lines to GEM detectors 2 gas vent lines

LaTech supplies

- 4 ribbon cables from V1495 in Doghouse to breakout box on rotator (2 ribbon cables for data I/O, 2 cables for trig/clock and DAC calibration) (Shielded twisted pair ribbon cable)

- 2 RJ45 I2C cables from dog house GUMstick upstream of target to breakout box on GEM rotator

- 6 (+2.5V) power lines from dog house to GEM rotator

Meeting Notes

3/5/09

1. Briefly review the current status of your system: is it

a) assembled

detector and rotator are assembled

b) tested

HV tested the detector. Rotator is tested and working

c) ready for shipping ? Not ready for shipping. If not, what are the remaining critical milestones and how will your group meet them?

Not ready for shipping. Remaining critical milestones are

i.)readout tests: The detector system (ionization chamber + DAQ readout) needs to be tested before installation into Hall C. The first test will use an electron beam at Idaho State University. The tests are on the schedule for the week of March 16. I believe this will slip by 1 month because of 3 problems which have occured with the accelerator. 6 VFAT readout cards are expected to be sent out the week of March 2, 2009.

ii.) Detector mounting system and signal cable holders: LaTech should provide input on this.

iii.) Slow Control GUI: LaTech Should provide input on this.

2. Briefly summarize the installation and integration issues when your system is installed at JLab. How will these be addressed?

i.) survey: the Detector has survey markers on the most downstream part which are visible outside the detector. Survey should be scheduled to prevent line of sight obstacles (ie, the 2nd collimator).

3. Describe the tests to be made with beam during the commissioning phase for your system. What analysis tasks will need to be done to confirm that it is ready for production mode?

a.) is the detector working test. You should see pulses on the trigger output signal. A BNC cable should be run from alenas electronics to the counting house.

b.) timing tests, Is the readout in sync with the JLAB RF

c.)Point target tracking test, does R1 and R2 reconstruct straight line tracks to the location of a solid target?

4. Briefly summarize the nature of the analysis software needed for your system and its current status. Who is in charge of this software for your group?

a.) Tracking software for a Q^2 straight track measurement.

5. Who is in charge of documentation (both hardware and software) for your system? How will general shift workers be trained to operate it?

a.) Documentation is needed to describe the Rotator control software (Klaus?), HV settings(?), and the VFAT setup procedure(Tony).

b.) a Tracking group member will be available during scheduled tracking shifts to operate the detectors and take data.

6. List the members of the team dedicated to installing, commissioning and running your system for Qweak. Indicate a schedule for who you plan to have at JLab and when.

My last version of the schedule has the following dates

3/18/10 Install rotator: K. Grimm

3/31/10 Install R1 Chamber: T. Forest: I am guessing that this means hook up power and the DAQ, I can put my name down.

4/21/10 Survey R1 chamber: Any want to sign up?

7/22/10: Qweak Commission: S. Wells + T. Forest?

7. Does your system require a dedicated expert on each shift? Do you need to recruit additional manpower from the collaboration at large?

Yes, see answer to #5 above.