Difference between revisions of "R3DC Report 2-08"

| Line 39: | Line 39: | ||

==Distributed Load Deflection== | ==Distributed Load Deflection== | ||

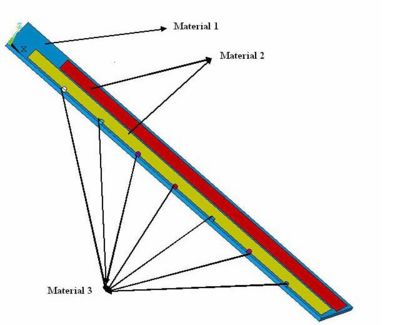

| − | The endplate deflection calculation was redone assuming a distributed load instead of a point load in order to determine how much the distribution of the load would help reduce the endplate deflection. The tension of the wires on the endplate was divided into three regions; W1,W2, and W3. . As shown in the Figure below, the load W3 corresponds to a region along the endplate in which wires from both super layers are creating a load on the endplate. Loads W1 and W2 represent regions in which only 1 super layer is causing a load. The endplate is "simply" supported in order to calculate the deflection. The "simple" support has a point support on the left side in which the endplate may rotate but not translate (move left or right). The right hand side of the plate is supported such that the endplate can both rotate and translate. The figure below labels the loads as well as distances over which the loads are applied on the end plate. | + | The endplate deflection calculation was redone assuming a distributed load instead of a point load in order to determine how much the distribution of the load would help reduce the endplate deflection. The tension of the wires on the endplate was divided into three regions; W1,W2, and W3. . As shown in the Figure below, the load W3 corresponds to a region along the endplate in which wires from both super layers are creating a load on the endplate. Loads W1 and W2 represent regions in which only 1 super layer is causing a load. The endplate is "simply" supported in order to calculate the deflection. The "simple" support has a point support on the left side in which the endplate may rotate but not translate (move left or right). The right hand side of the plate is supported such that the endplate can both rotate and translate. The figure below labels the loads as well as distances over which the loads are applied on the end plate. A wire tension of 340 lbs is decomposed into its components due to the angle made by the wire on the endplate. |

{| border="1" |cellpadding="20" cellspacing="0 | {| border="1" |cellpadding="20" cellspacing="0 | ||

Revision as of 00:50, 8 February 2008

Introduction

R3 Description

Geometry

Material Specifications

| Material | Youngs Modulus | Density |

| MPa | ||

| Polyeurethane Foam FR-3700 | 140 | 240 |

| Hexacell with holes | ||

| Carbon Fiber Rods | 210 | 580 |

Specific part Drawings

Endplate Deflection

Point Load Deflection

A simple calculation based on the definition of Young's modulus can yield an order of magnitude level estimate for the deflection of an endplate made from Aluminum. According to the definition of Young's modulus

where

- Young's Modulus for Aluminum

- point force/load

- width of the endplate

- deflection of endplate due to point force

- length of the endplate

- thickness of the endplate

A deflection of 6 mm is expected for a 5 cm thick Aluminum endplate, after solving the above equation for and inserting the given values. If a 5 cm thick stainless steel endplate were used, the deflection would drop a factor of 3 from 6 mm to 2 mm due to the linear dependence of the deflection on Young's Modulus. The previous work of Kevin Folkman led to a similar conclusion.

Distributed Load Deflection

The endplate deflection calculation was redone assuming a distributed load instead of a point load in order to determine how much the distribution of the load would help reduce the endplate deflection. The tension of the wires on the endplate was divided into three regions; W1,W2, and W3. . As shown in the Figure below, the load W3 corresponds to a region along the endplate in which wires from both super layers are creating a load on the endplate. Loads W1 and W2 represent regions in which only 1 super layer is causing a load. The endplate is "simply" supported in order to calculate the deflection. The "simple" support has a point support on the left side in which the endplate may rotate but not translate (move left or right). The right hand side of the plate is supported such that the endplate can both rotate and translate. The figure below labels the loads as well as distances over which the loads are applied on the end plate. A wire tension of 340 lbs is decomposed into its components due to the angle made by the wire on the endplate.

| Label | value |

| a | 99.02 mm |

| b | 96.22 mm |

| c | 4025.88 mm |

| d | 335.17 mm |

| e | 273.88 mm |

| 0.255 N/mm | |

| 0.59 N/mm | |

| 0.335 N/mm |

Distributed load FEA

In addition to validating the FEA analysis with hand calculations, the above results also reveal the challenge of reducing the endplate deflection using stiffer Materials due to an essentially linear dependence of the deflection to Young's Modulus. The cubic dependence of the deflection on the thickness of the endplate, however, can be used to reach the minimum endplate deflection criteria of 50 instead of using stiffer material. Increasing the endplate thickness comes at the cost of increasing the end plate mass. As a result, composite materials were considered in order to minimize weight.

Carbon Rod Buckling

Compression

Buckling Load Threshold

Buckling FEA

=3-D Analysis