Difference between revisions of "Radiators Temperature"

(→Al) |

|||

| (56 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | [http://wiki.iac.isu.edu/index.php/HRRL Go Back] | ||

| + | |||

| + | |||

=Calculating Radiators Equilibrium Temperature= | =Calculating Radiators Equilibrium Temperature= | ||

==1.Calculating number of particles per second == | ==1.Calculating number of particles per second == | ||

| Line 22: | Line 25: | ||

So, we have around 3.12075*1012 electrons hit radiator per second. | So, we have around 3.12075*1012 electrons hit radiator per second. | ||

| − | |||

| − | |||

==2.Calculating Energy deposited per second== | ==2.Calculating Energy deposited per second== | ||

| Line 67: | Line 68: | ||

|- | |- | ||

|Elements | |Elements | ||

| − | |<math>(dE/dx)_{coll}</math> | + | |<math>(dE/dx)_{coll} (MeV \; cm^2/g)</math> |

|t( <math> gcm^{-2}</math>) | |t( <math> gcm^{-2}</math>) | ||

|<math>E_{dep one}</math> (MeV) | |<math>E_{dep one}</math> (MeV) | ||

| Line 86: | Line 87: | ||

<math>P{dep}= E{dep/s} = ( E {dep by one})*(Number of electron per second)</math> | <math>P{dep}= E{dep/s} = ( E {dep by one})*(Number of electron per second)</math> | ||

| + | |||

==3.Calculating equilibrium temperature using Stefan–Boltzmann law== | ==3.Calculating equilibrium temperature using Stefan–Boltzmann law== | ||

If we assume that there is no energy conduction and total energy is just radiated from two surfaces of the radiators which are as big as beam spot,in our case beam spot is 2mm in diameter. According to Stefan–Boltzmann law, this total power radiated will be | If we assume that there is no energy conduction and total energy is just radiated from two surfaces of the radiators which are as big as beam spot,in our case beam spot is 2mm in diameter. According to Stefan–Boltzmann law, this total power radiated will be | ||

| Line 122: | Line 124: | ||

==4. Results for different Thicknesses and Spot sizes == | ==4. Results for different Thicknesses and Spot sizes == | ||

| − | We can calculate separately for Al, W and Ti for different thickness and different beam spot diameter. Following tables are temperature calculation for Al, W and | + | We can calculate separately for Al, W and Ti for different thickness and different beam spot diameter. Following tables are temperature calculation for Al, W Ti and Fe in thickness of 0.001, 0.005 and 0.01 times of Radiation Length, in beam spot of diameter of 2, 4, 6, 8, 10 mm. |

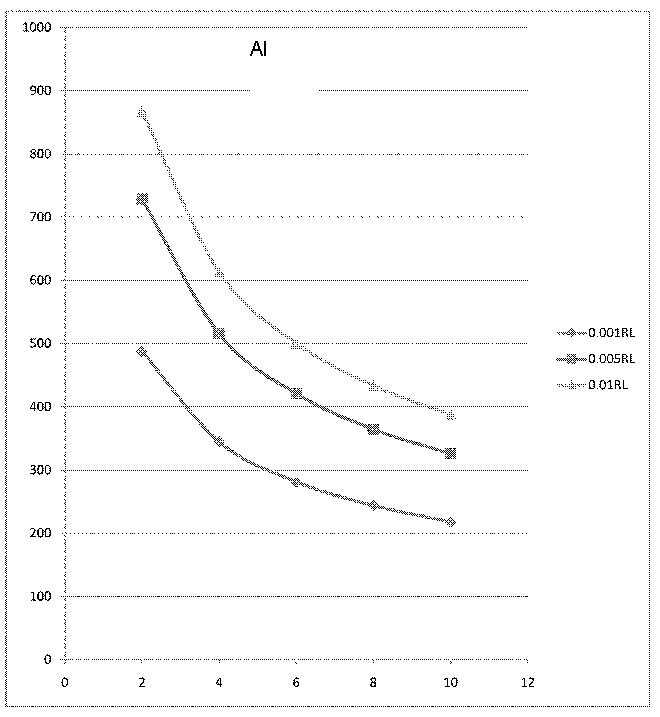

===Al=== | ===Al=== | ||

| Line 137: | Line 139: | ||

|10(mm) | |10(mm) | ||

|- | |- | ||

| − | |||

|- | |- | ||

| − | |0.001Rl || || || || || || | + | |0.001RlK || 487.5 K||344.7 K || 281.5 K|| 234.8 K|| 218.0 K |

| + | |- | ||

| + | |0.005Rl K|| 729.1 K||515.5 K||420.9 K||364.5 K|| 326.0 K | ||

| + | |- | ||

| + | |0.01Rl K || 867.0 K|| 613.1 K|| 550.6 K||433.5 K||387.7 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | [[Image:Equilibrium Temperature for Al .jpg]] | ||

| + | |||

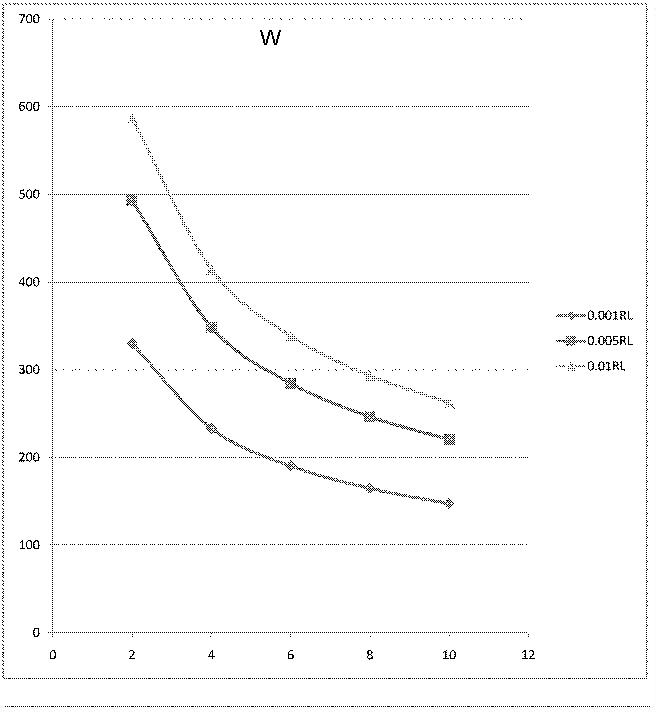

| + | ===W=== | ||

| + | Equilibrium temperature for W, unit is K. (Melting point of W is 3695K) | ||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |2(mm) | ||

| + | |4(mm) | ||

| + | |6(mm) | ||

| + | |8(mm) | ||

| + | |10(mm) | ||

| + | |- | ||

| + | |- | ||

| + | |0.001Rl || 239.8 K||233.2 K||190.4 K||164.9 K|| 147.5 K | ||

| + | |- | ||

| + | |0.005Rl ||493.2 K|| 348.7 K||248.7 K||246.6 K|| 220.6 K | ||

| + | |- | ||

| + | |0.01Rl ||586.5 K||414.7 K|| 338.6 K|| 293.3 K|| 262.3 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | [[Image:Equilibrium Temperature for W.jpg]] | ||

| + | |||

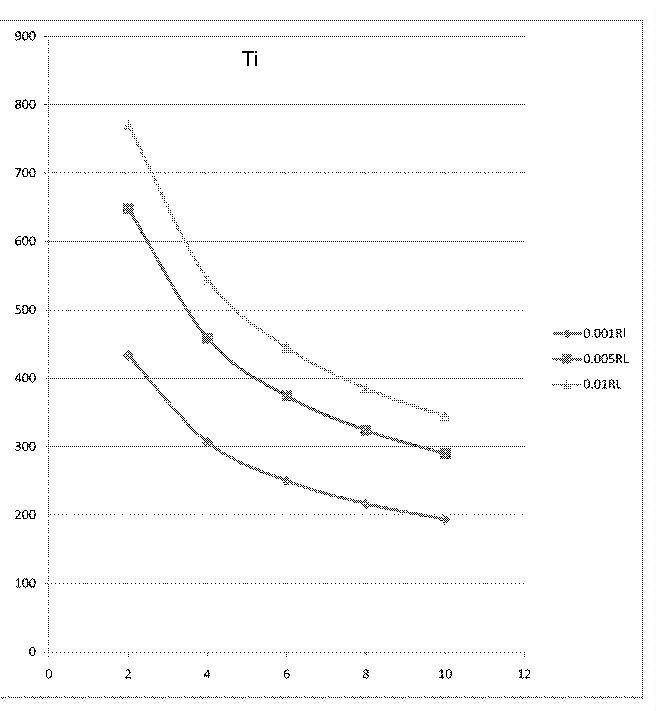

| + | ===Ti=== | ||

| + | Equilibrium temperature for Ti, unit is K. (Melting point of Ti is 1941K) | ||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |2(mm) | ||

| + | |4(mm) | ||

| + | |6(mm) | ||

| + | |8(mm) | ||

| + | |10(mm) | ||

| + | |- | ||

| + | |- | ||

| + | |0.001Rl || 433.4 K||306.5 K|| 250.2 K||216.7 K||193.8 K | ||

| + | |- | ||

| + | |0.005Rl || 648.1 K|| 458.3 K|| 374.2 K|| 324.0 K|| 289.8 K | ||

| + | |- | ||

| + | |0.01Rl ||770.7 K||545.0 K|| 445.0 K||385.4 K|| 344.7 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | [[Image:Equilibrium Temperature for Ti.jpg]] | ||

| + | |||

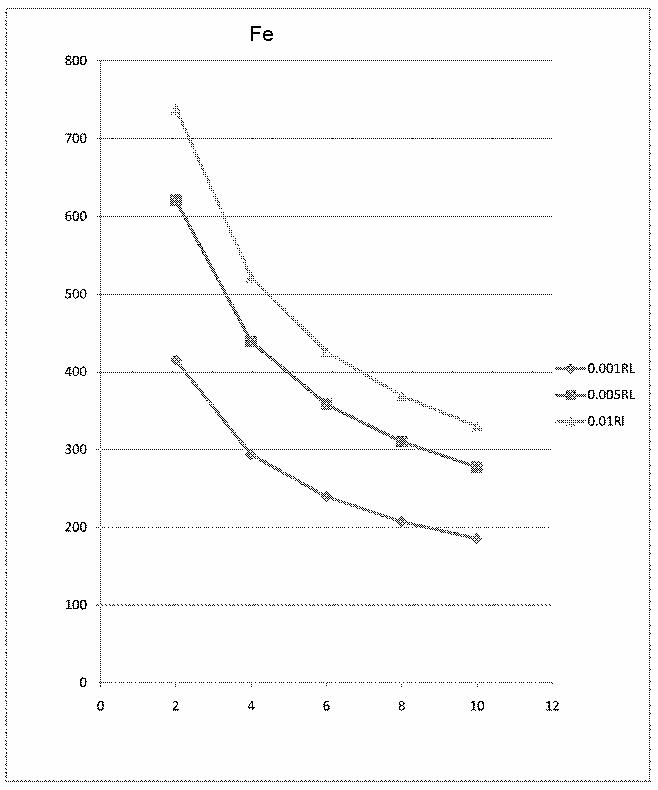

| + | ===Fe=== | ||

| + | Equilibrium temperature for Fe, unit is K. (Melting point of Fe is 1811 K) | ||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |2(mm) | ||

| + | |4(mm) | ||

| + | |6(mm) | ||

| + | |8(mm) | ||

| + | |10(mm) | ||

| + | |- | ||

| + | |- | ||

| + | |0.001Rl || 415.2 K|| 293.6 K||239.7 K||207.6 K|| 185.7 K | ||

| + | |- | ||

| + | |0.005Rl || 620.8 K||439.0 K|| 358.4 K||310.4 K|| 277.6 K | ||

| + | |- | ||

| + | |0.01Rl ||738.3 K|| 522.1 K||426.3 K||369.2 K||330.2 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | [[Image:Equilibrium Temperature for Fe.jpg]] | ||

| + | |||

| + | |||

| + | |||

| + | ==5. Results for worst cases ( 80mA peak current,1000Hz frequency, 50ns pulse width ) == | ||

| + | |||

| + | Now we calculate temperature for Al, W, Ti and Fe for different thickness and different beam spot diameter in worst case . Following tables are temperature calculation for Al, W Ti and Fe in thickness of 0.00001, 0.0005 and 0.0001 times of Radiation Length, in beam spot of diameter of 2, 3, 4 mm. | ||

| + | |||

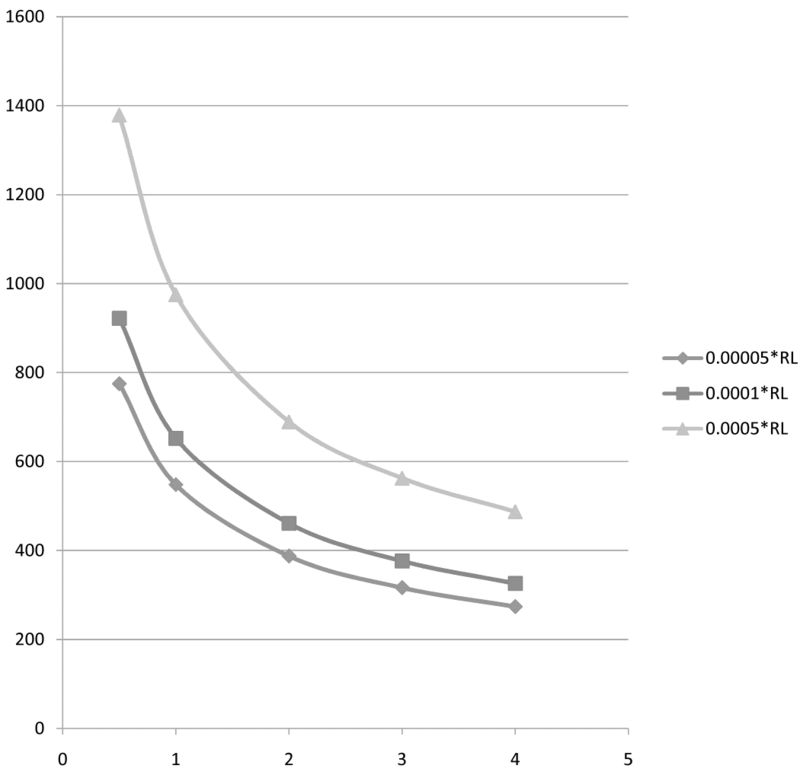

| + | ===Al=== | ||

| + | Equilibrium temperature for Al, unit is K. (Melting point of Al is 933K) | ||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |1(mm) | ||

| + | |2(mm) | ||

| + | |3(mm) | ||

| + | |4(mm) | ||

| + | |- | ||

| + | |- | ||

| + | |0.00005Rl || 548 K||387 K || 317 K||274 K | ||

| + | |- | ||

| + | |0.0001Rl || 652 K||461 K|| 376 K||326 K | ||

| + | |- | ||

| + | |0.0005Rl || 975 K|| 689 K||562 K|| 487 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | [[Image:Al_2.jpg|down|800px]] | ||

| + | |||

| + | |||

| + | ===W=== | ||

| + | Equilibrium temperature for W, unit is K. (Melting point of Al is 3695K) | ||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |1(mm) | ||

| + | |2(mm) | ||

| + | |3(mm) | ||

| + | |4(mm) | ||

| + | |- | ||

| + | |- | ||

| + | |0.00005Rl ||370 K||262 K || 214 K|| 158 K | ||

| + | |- | ||

| + | |0.0001Rl ||441 K||312 K||254 K||220 K | ||

| + | |- | ||

| + | |0.0005Rl ||660 K|| 446 K|| 381 K||330 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | [[Image:W_2.jpg|down|800px]] | ||

| + | |||

| + | |||

| + | |||

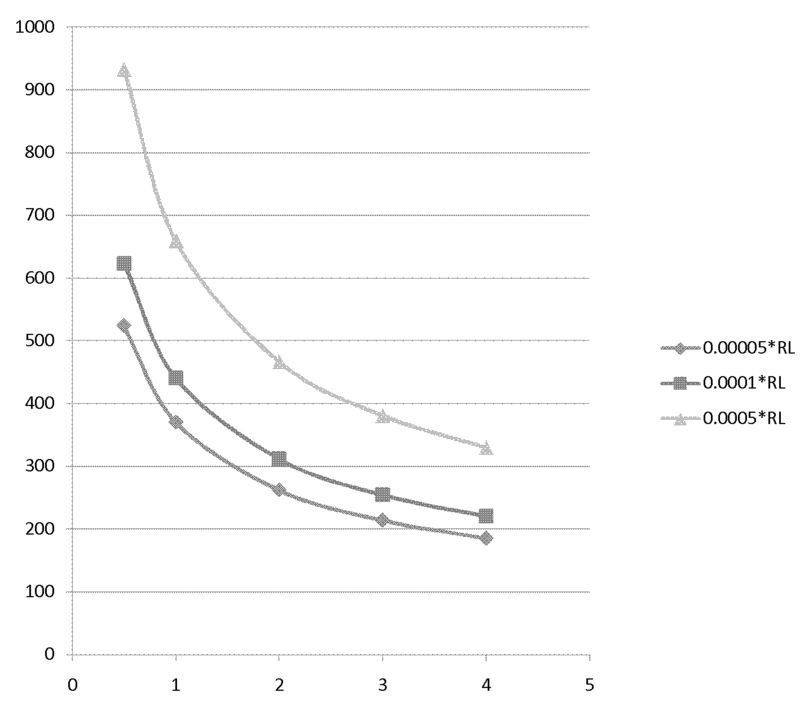

| + | ===Ti=== | ||

| + | Equilibrium temperature for Ti, unit is K. (Melting point of Ti is 1941K) | ||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |1(mm) | ||

| + | |2(mm) | ||

| + | |3(mm) | ||

| + | |4(mm) | ||

| + | |- | ||

| + | |- | ||

| + | |0.00005Rl || 487 K||334 K || 281 K|| 244 K | ||

| + | |- | ||

| + | |0.0001Rl || 597 K||410 K||335 K|| 290 K | ||

| + | |- | ||

| + | |0.0005Rl || 1226 K|| 867 K|| 500 K|| 433 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | [[Image:Ti_2.jpg|down|800px]] | ||

| + | |||

| + | |||

| + | |||

| + | ===Fe=== | ||

| + | Equilibrium temperature for Fe, unit is K. (Melting point of Fe is 1811 K) | ||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |1(mm) | ||

| + | |2(mm) | ||

| + | |3(mm) | ||

| + | |4(mm) | ||

| + | |- | ||

| + | |- | ||

| + | |0.00005Rl || 467 K||330 K || 270 K|| 233 K | ||

| + | |- | ||

| + | |0.0001Rl || 555 K||393 K||321 K||278 K | ||

| + | |- | ||

| + | |0.0005Rl ||830 K|| 587 K|| 479 K||415 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | [[Image:Fe_2.jpg|down|800px]] | ||

| + | |||

| + | |||

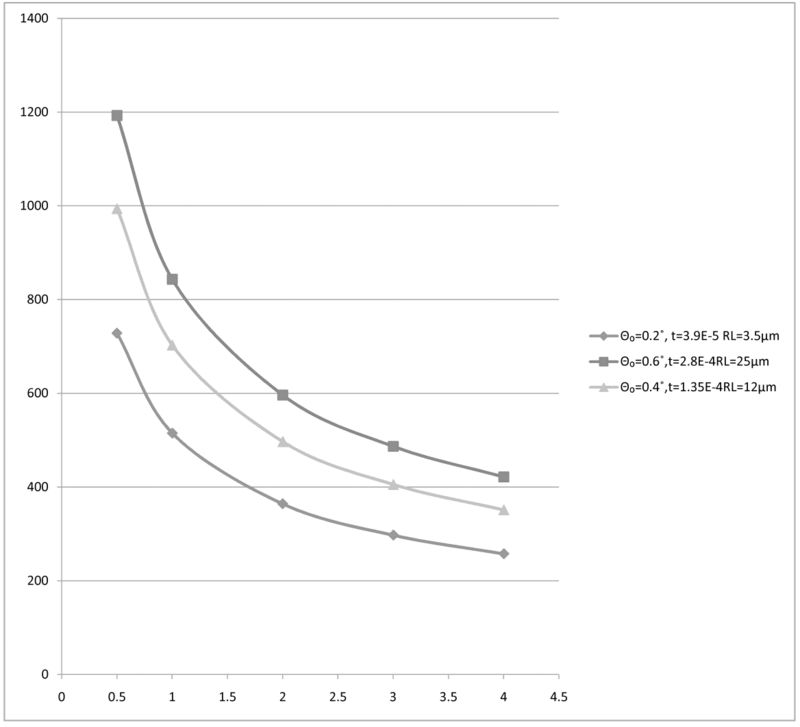

| + | ==6. More results for worst cases ( 80mA peak current,1000Hz frequency, 50ns pulse width for Θ₀ = 0.2,0.4,0.6 dgrees) == | ||

| + | |||

| + | Now we calculate temperature for Al, W, Ti and Fe for different thickness and different beam spot diameter in worst case . Following tables are temperature calculation for Al, W Ti and Fe in thickness of <math>3.9*10^{-5}</math> (Θ₀ = <math>0.2^{o}</math>), <math>1.35*10^{-4}</math>(Θ₀= <math>0.4^{o}</math>) and <math>2.8*10^{-4}</math>(Θ₀ = <math>0.6^{o}</math>) times of Radiation Length, in beam spot of diameter of 2, 3, 4 mm. | ||

| + | |||

| + | ===Al=== | ||

| + | Equilibrium temperature for Al, unit is K. (Melting point of Al is 933K) | ||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |2(mm) | ||

| + | |3(mm) | ||

| + | |4(mm) | ||

| + | |- | ||

| + | |- | ||

| + | |Θ₀=0.2˚, t=3.9E-5 RL=3.5μm|| 364 K|| 298 K|| 258 K | ||

| + | |- | ||

| + | |Θ₀=0.4˚,t=1.35E-4RL=12μm || 497 K|| 406 K|| 351 K | ||

| + | |- | ||

| + | |Θ₀=0.6˚,t=2.8E-4RL=25μm || 596 K|| 487 K|| 422 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | [[Image:Al_3.jpg|down|800px]] | ||

| + | |||

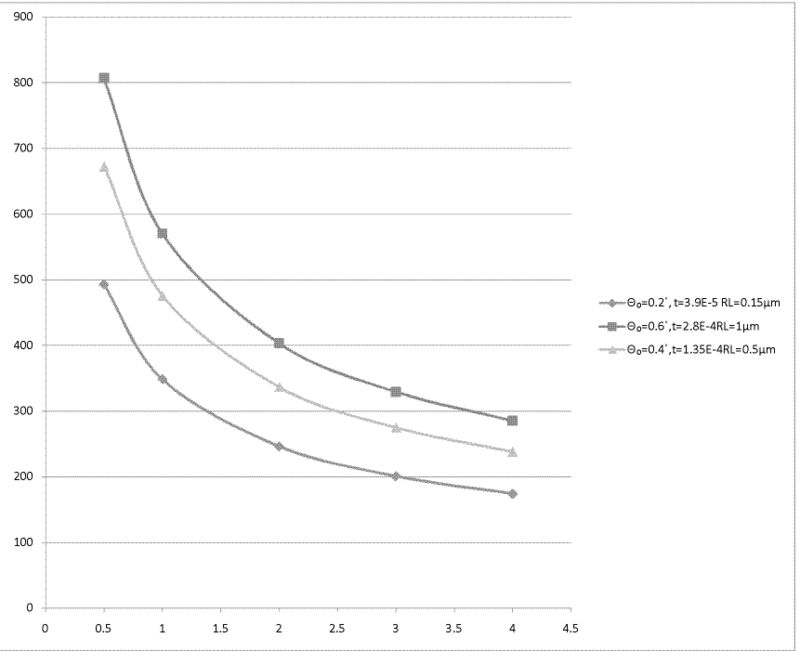

| + | ===W=== | ||

| + | Equilibrium temperature for W, unit is K. (Melting point of Al is 3695K) | ||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |2(mm) | ||

| + | |3(mm) | ||

| + | |4(mm) | ||

| + | |- | ||

| + | |- | ||

| + | | Θ₀=0.2˚, t=3.9E-5 RL=0.15μm|| 246 K|| 201 K|| 174 K | ||

| + | |- | ||

| + | | Θ₀=0.4˚,t=1.35E-4RL=0.5μm || 336 K|| 275 K|| 237 K | ||

| + | |- | ||

| + | | Θ₀=0.6˚,t=2.8E-4RL=1μm || 404 K|| 329 K|| 285 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | |||

| + | [[Image:W_3.jpg|down|800px]] | ||

| + | |||

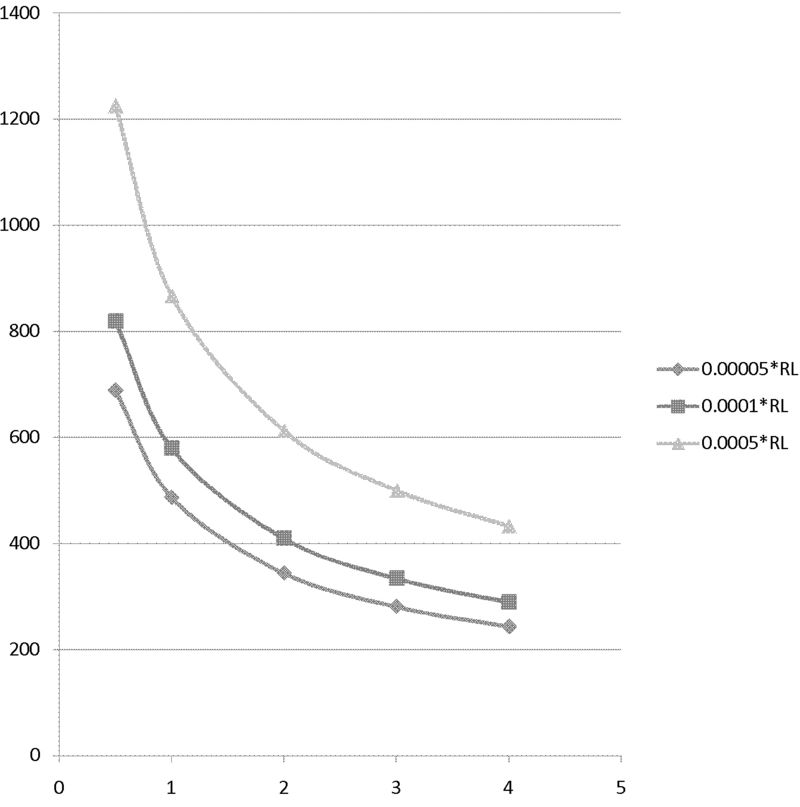

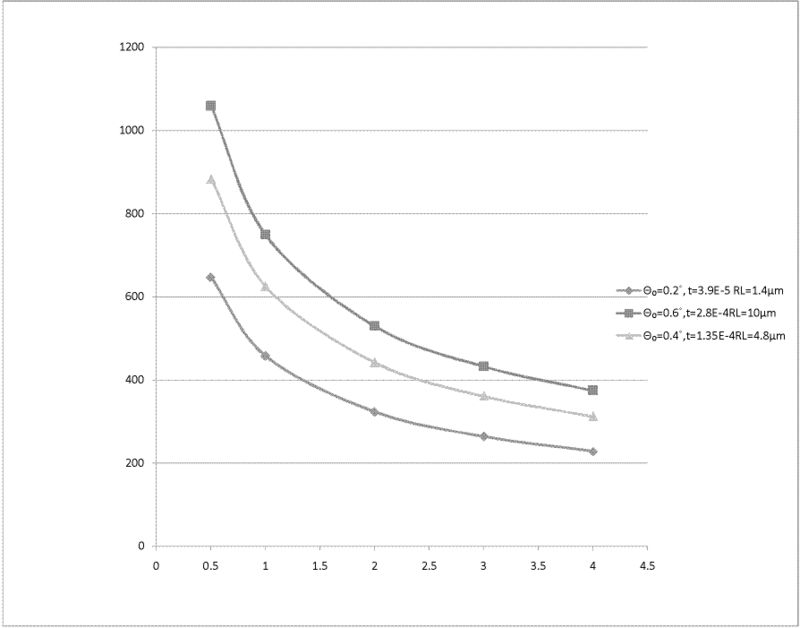

| + | ===Ti=== | ||

| + | Equilibrium temperature for Ti, unit is K. (Melting point of Ti is 1941K) | ||

| + | |||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |2(mm) | ||

| + | |3(mm) | ||

| + | |4(mm) | ||

| + | |- | ||

| + | |- | ||

| + | | Θ₀=0.2˚, t=3.9E-5 RL=1.4μm|| 329 K|| 264 K|| 229 K | ||

|- | |- | ||

| − | |0. | + | | Θ₀=0.4˚,t=1.35E-4RL=4.8μm || 442 K|| 360 K|| 312 K |

|- | |- | ||

| − | |0. | + | | Θ₀=0.6˚,t=2.8E-4RL=10μm || 530 K|| 432 K|| 375 K |

|- | |- | ||

|} | |} | ||

| + | |||

| + | [[Image:Ti_3.jpg|down|800px]] | ||

| + | |||

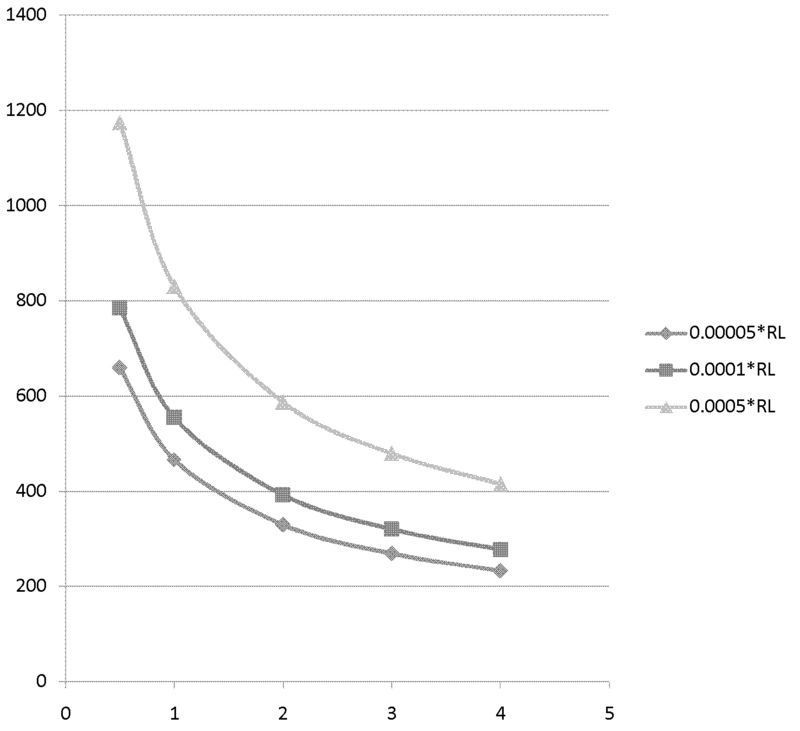

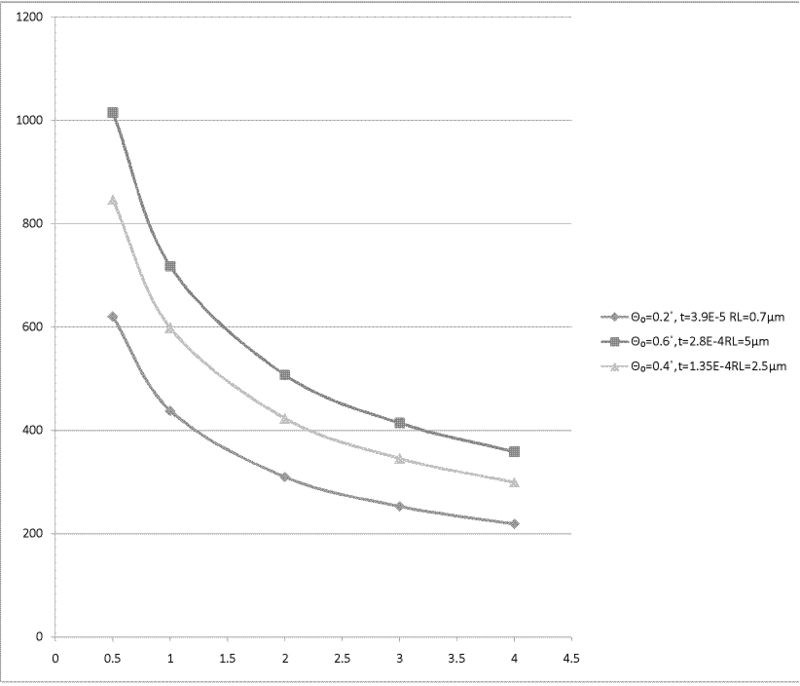

| + | ===Fe=== | ||

| + | Equilibrium temperature for Fe, unit is K. (Melting point of Fe is 1811 K) | ||

| + | |||

| + | |||

| + | {| border="1" cellpadding="20" cellspacing="0" | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | |2(mm) | ||

| + | |3(mm) | ||

| + | |4(mm) | ||

| + | |- | ||

| + | |- | ||

| + | | Θ₀=0.2˚, t=3.9E-5 RL=0.7μm|| 310 K|| 253 K|| 219 K | ||

| + | |- | ||

| + | | Θ₀=0.4˚,t=1.35E-4RL=2.5μm || 423 K|| 346 K|| 299 K | ||

| + | |- | ||

| + | | Θ₀=0.6˚,t=2.8E-4RL=5μm || 508 K|| 415 K|| 359 K | ||

| + | |- | ||

| + | |} | ||

| + | |||

| + | [[Image:Fe_3.jpg|down|800px]] | ||

| + | |||

| + | [http://wiki.iac.isu.edu/index.php/HRRL Go Back] | ||

Latest revision as of 06:34, 5 February 2009

Calculating Radiators Equilibrium Temperature

1.Calculating number of particles per second

We have electron beam of:

Frequency: f=1000Hz

Peak current: I=10mAmp=0.01 Amp

Pulse width: ∆t= 50 ns=5*10-8 seconds

So, how many electrons we have in each second?

By Q=It, we have

N*e=f*I*∆t

Where Ne is the total electron numbers hits target per second, e is electron charge and f, I and ∆t are given above. So

N= f*I*∆t/e=1000*0.01*5*10-8/(1.6*10-19)=3.12075*1012

So, we have around 3.12075*1012 electrons hit radiator per second.

2.Calculating Energy deposited per second

If we find the energy deposited by each electron and multiply to the total number of electrons in each second, we will find the total energy per second deposited in radiator.

To find energy deposited by each electron, we need to use formula

Where is is energy deposited by one electron, is mean energy loss (also stopping power) by collision of electron and t is thickness of the radiator.

Actually, energy loss of electron comes from two parts: the emission of electromagnetic radiation arising from scattering in the electric field of a nucleus (bremsstrahlung) and collisional energy loss when passing through matter. But bremsstrahlung will not contribute to the temperature, since it is radiation.

Stopping power can be found from nuclear data tables and thickness is 0.001 times of radiation length. From Particle Data group we got radiation length and average total stopping powers around 15MeV for electrons in these materials from National Institute of Standards and Technology

Table of Radiation Lengths

Note:These data is from Particle Data group,Link: [1].

| Elements | Radiation Lengths |

| Al | 24.01 |

| W | 6.76 |

| Ti | 16.16 |

| Fe | 13.84 |

Table of energy calculations

For the thickness of 0.001 Radiation Length (0.0001RL) of radiators. Note: is from National Institute of Standards and Technology. Link: [[2]])

| Elements | t( ) | (MeV) | (MeV/s) | (J/s) | |

| Al | 1.676 | 0.02401 | 0.00402076 | ||

| W | 1.247 | 0.00676 | 0.00842972 | ||

| Ti | 1.555 | 0.01616 | 0.0251288 | ||

| Fe | 1.529 | 0.01384 | 0.02116136 |

In above table,we took the total numbers of electrons per second and multiply it to Energy deposited by one electron,get total energy deposited per second (which is power).

3.Calculating equilibrium temperature using Stefan–Boltzmann law

If we assume that there is no energy conduction and total energy is just radiated from two surfaces of the radiators which are as big as beam spot,in our case beam spot is 2mm in diameter. According to Stefan–Boltzmann law, this total power radiated will be

= 2Aσ

Where T is radiating temperature P is the radiating power, A is surface area that beam incident and σ is Stefan–Boltzmann constant or Stefan's constant. To reach equilibrium temperature, Power deposited in and power radiated should be. So

so

T =[/(2Aσ)]^{1/4}

Table of equilibrium temperatures

For 2mm diameter spot size and 0.001 time Radiation Length thickness

| Elements | d (m) | 2A( ) | Stefan-Boltzmann Constant | (K) |

| Al | 0.002 | 0.00000628 | 487.5 | |

| W | 0.002 | 0.00000628 | 329.8 | |

| Ti | 0.002 | 0.00000628 | 433.4 | |

| Fe | 0.002 | 0.00000628 | 415.2 |

4. Results for different Thicknesses and Spot sizes

We can calculate separately for Al, W and Ti for different thickness and different beam spot diameter. Following tables are temperature calculation for Al, W Ti and Fe in thickness of 0.001, 0.005 and 0.01 times of Radiation Length, in beam spot of diameter of 2, 4, 6, 8, 10 mm.

Al

Equilibrium temperature for Al, unit is K. (Melting point of Al is 933K)

| 2(mm) | 4(mm) | 6(mm) | 8(mm) | 10(mm) | |

| 0.001RlK | 487.5 K | 344.7 K | 281.5 K | 234.8 K | 218.0 K |

| 0.005Rl K | 729.1 K | 515.5 K | 420.9 K | 364.5 K | 326.0 K |

| 0.01Rl K | 867.0 K | 613.1 K | 550.6 K | 433.5 K | 387.7 K |

W

Equilibrium temperature for W, unit is K. (Melting point of W is 3695K)

| 2(mm) | 4(mm) | 6(mm) | 8(mm) | 10(mm) | |

| 0.001Rl | 239.8 K | 233.2 K | 190.4 K | 164.9 K | 147.5 K |

| 0.005Rl | 493.2 K | 348.7 K | 248.7 K | 246.6 K | 220.6 K |

| 0.01Rl | 586.5 K | 414.7 K | 338.6 K | 293.3 K | 262.3 K |

Ti

Equilibrium temperature for Ti, unit is K. (Melting point of Ti is 1941K)

| 2(mm) | 4(mm) | 6(mm) | 8(mm) | 10(mm) | |

| 0.001Rl | 433.4 K | 306.5 K | 250.2 K | 216.7 K | 193.8 K |

| 0.005Rl | 648.1 K | 458.3 K | 374.2 K | 324.0 K | 289.8 K |

| 0.01Rl | 770.7 K | 545.0 K | 445.0 K | 385.4 K | 344.7 K |

Fe

Equilibrium temperature for Fe, unit is K. (Melting point of Fe is 1811 K)

| 2(mm) | 4(mm) | 6(mm) | 8(mm) | 10(mm) | |

| 0.001Rl | 415.2 K | 293.6 K | 239.7 K | 207.6 K | 185.7 K |

| 0.005Rl | 620.8 K | 439.0 K | 358.4 K | 310.4 K | 277.6 K |

| 0.01Rl | 738.3 K | 522.1 K | 426.3 K | 369.2 K | 330.2 K |

5. Results for worst cases ( 80mA peak current,1000Hz frequency, 50ns pulse width )

Now we calculate temperature for Al, W, Ti and Fe for different thickness and different beam spot diameter in worst case . Following tables are temperature calculation for Al, W Ti and Fe in thickness of 0.00001, 0.0005 and 0.0001 times of Radiation Length, in beam spot of diameter of 2, 3, 4 mm.

Al

Equilibrium temperature for Al, unit is K. (Melting point of Al is 933K)

| 1(mm) | 2(mm) | 3(mm) | 4(mm) | |

| 0.00005Rl | 548 K | 387 K | 317 K | 274 K |

| 0.0001Rl | 652 K | 461 K | 376 K | 326 K |

| 0.0005Rl | 975 K | 689 K | 562 K | 487 K |

W

Equilibrium temperature for W, unit is K. (Melting point of Al is 3695K)

| 1(mm) | 2(mm) | 3(mm) | 4(mm) | |

| 0.00005Rl | 370 K | 262 K | 214 K | 158 K |

| 0.0001Rl | 441 K | 312 K | 254 K | 220 K |

| 0.0005Rl | 660 K | 446 K | 381 K | 330 K |

Ti

Equilibrium temperature for Ti, unit is K. (Melting point of Ti is 1941K)

| 1(mm) | 2(mm) | 3(mm) | 4(mm) | |

| 0.00005Rl | 487 K | 334 K | 281 K | 244 K |

| 0.0001Rl | 597 K | 410 K | 335 K | 290 K |

| 0.0005Rl | 1226 K | 867 K | 500 K | 433 K |

Fe

Equilibrium temperature for Fe, unit is K. (Melting point of Fe is 1811 K)

| 1(mm) | 2(mm) | 3(mm) | 4(mm) | |

| 0.00005Rl | 467 K | 330 K | 270 K | 233 K |

| 0.0001Rl | 555 K | 393 K | 321 K | 278 K |

| 0.0005Rl | 830 K | 587 K | 479 K | 415 K |

6. More results for worst cases ( 80mA peak current,1000Hz frequency, 50ns pulse width for Θ₀ = 0.2,0.4,0.6 dgrees)

Now we calculate temperature for Al, W, Ti and Fe for different thickness and different beam spot diameter in worst case . Following tables are temperature calculation for Al, W Ti and Fe in thickness of (Θ₀ = ), (Θ₀= ) and (Θ₀ = ) times of Radiation Length, in beam spot of diameter of 2, 3, 4 mm.

Al

Equilibrium temperature for Al, unit is K. (Melting point of Al is 933K)

| 2(mm) | 3(mm) | 4(mm) | |

| Θ₀=0.2˚, t=3.9E-5 RL=3.5μm | 364 K | 298 K | 258 K |

| Θ₀=0.4˚,t=1.35E-4RL=12μm | 497 K | 406 K | 351 K |

| Θ₀=0.6˚,t=2.8E-4RL=25μm | 596 K | 487 K | 422 K |

W

Equilibrium temperature for W, unit is K. (Melting point of Al is 3695K)

| 2(mm) | 3(mm) | 4(mm) | |

| Θ₀=0.2˚, t=3.9E-5 RL=0.15μm | 246 K | 201 K | 174 K |

| Θ₀=0.4˚,t=1.35E-4RL=0.5μm | 336 K | 275 K | 237 K |

| Θ₀=0.6˚,t=2.8E-4RL=1μm | 404 K | 329 K | 285 K |

Ti

Equilibrium temperature for Ti, unit is K. (Melting point of Ti is 1941K)

| 2(mm) | 3(mm) | 4(mm) | |

| Θ₀=0.2˚, t=3.9E-5 RL=1.4μm | 329 K | 264 K | 229 K |

| Θ₀=0.4˚,t=1.35E-4RL=4.8μm | 442 K | 360 K | 312 K |

| Θ₀=0.6˚,t=2.8E-4RL=10μm | 530 K | 432 K | 375 K |

Fe

Equilibrium temperature for Fe, unit is K. (Melting point of Fe is 1811 K)

| 2(mm) | 3(mm) | 4(mm) | |

| Θ₀=0.2˚, t=3.9E-5 RL=0.7μm | 310 K | 253 K | 219 K |

| Θ₀=0.4˚,t=1.35E-4RL=2.5μm | 423 K | 346 K | 299 K |

| Θ₀=0.6˚,t=2.8E-4RL=5μm | 508 K | 415 K | 359 K |