Difference between revisions of "PAS Shielding"

Jump to navigation

Jump to search

(Created page with "BorAl Various concentrations of Borated Polyethylene Polyethylene Lead ---- PAS_Experiment") |

|||

| (14 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | ='''Lead'''= | |

| − | + | =='''Lead Bricks'''== | |

| − | + | ===5/11/21=== | |

| − | + | Painted half size lead bricks (1"x4"x8") with red epoxy based paint for safer handling when building shielding arrays. Made the mistake of letting them dry on porous surface and now have to find way to remove cardboard that is sealed to the last unpainted side of bricks. | |

| + | [[File:PAS_Painted_Lead_Bricks_1.jpg|300px|thumb|left|Half of the first set of painted lead bricks on cardboard drying surface.]] | ||

| + | [[File:PAS_Painted_Lead_Bricks_2.jpg|300px|thumb|center|Half of the first set of painted lead bricks on cardboard drying surface.]] | ||

| + | |||

| + | |||

| + | |||

| + | ===5/27/21=== | ||

| + | |||

| + | Finished painting lead bricks which need to dry/cure for 24-48hrs | ||

| + | |||

| + | ===6/1/21=== | ||

| + | |||

| + | *Moved dried/cured painted lead bricks from painting area to clean room | ||

| + | |||

| + | *Cleaned each brick with a wet wipe before transition into clean room, will be allowed to air dry on steel table | ||

| + | |||

| + | *50 bricks total: 49 half bricks and 1 full brick | ||

| + | |||

| + | [[File:CH_Fully_Painted_Pb_Bricks.jpg|300px|thumb|none|Fully painted lead bricks air drying on steel table after wipe down]] | ||

| + | |||

| + | == '''Lead Sheet''' == | ||

| + | |||

| + | ===5/17/21 - 5/18/21=== | ||

| + | |||

| + | Sheared a lead sheet into 6 rough 3"x3" squares to be used for attenuation measurements with NaI detectors | ||

| + | |||

| + | Lead pieces were wiped down with a wet wipe, duct taped, rewiped, and hammered flat. | ||

| + | |||

| + | Thickness of the lead pieces is around 0.055". | ||

| + | |||

| + | |||

| + | [[File:PAS_Lead_Sheet_Full_Bare.jpg|300px|thumb|left|Half of the first set of painted lead bricks on cardboard drying surface.]] | ||

| + | |||

| + | |||

| + | [[File:PAS_Lead_Sheet_Edge_Bare.jpg|300px|thumb|center|Half of the first set of painted lead bricks on cardboard drying surface.]] | ||

| + | |||

| + | |||

| + | [[File:PAS_Lead_Sheet_Full_Taped.jpg|300px|thumb|left|Half of the first set of painted lead bricks on cardboard drying surface.]] | ||

| + | |||

| + | |||

| + | [[File:PAS_Lead_Sheet_Edge_Taped.jpg|300px|thumb|center|Half of the first set of painted lead bricks on cardboard drying surface.]] | ||

| + | |||

| + | ='''Borated Aluminum'''= | ||

| + | |||

| + | B12 and B4C structures in aluminum | ||

| + | |||

| + | * Might be possible to separate the aluminum with elemental mercury or could melt the aluminum | ||

| + | ** Aluminum oxide has a higher melting point (~2000C) than elemental aluminum which is still lower than B4C (~2700C) | ||

| + | |||

| + | ='''Polyethylene'''= | ||

| + | |||

| + | ==Borated Polyethylene== | ||

| + | |||

| + | ===Virgin Polyethylene=== | ||

| + | |||

| + | ===Green Borated Polyethylene=== | ||

| + | |||

| + | *The concentration of boron is unknown at the current time | ||

| + | |||

| + | ===Light Purple Borated Polyethylene=== | ||

| + | |||

| + | *The concentration of boron is unknown at the current time | ||

---- | ---- | ||

[[PAS_Experiment]] | [[PAS_Experiment]] | ||

Latest revision as of 19:33, 20 December 2022

Lead

Lead Bricks

5/11/21

Painted half size lead bricks (1"x4"x8") with red epoxy based paint for safer handling when building shielding arrays. Made the mistake of letting them dry on porous surface and now have to find way to remove cardboard that is sealed to the last unpainted side of bricks.

5/27/21

Finished painting lead bricks which need to dry/cure for 24-48hrs

6/1/21

- Moved dried/cured painted lead bricks from painting area to clean room

- Cleaned each brick with a wet wipe before transition into clean room, will be allowed to air dry on steel table

- 50 bricks total: 49 half bricks and 1 full brick

Lead Sheet

5/17/21 - 5/18/21

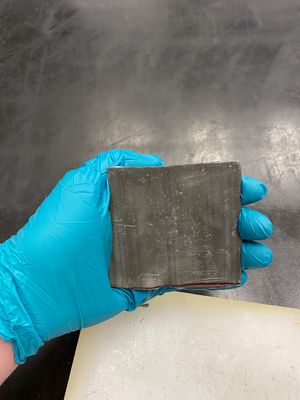

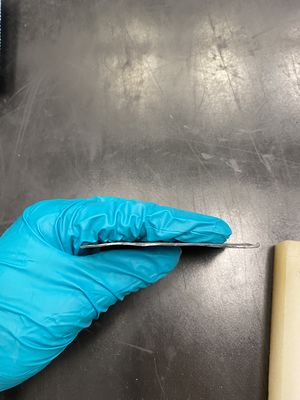

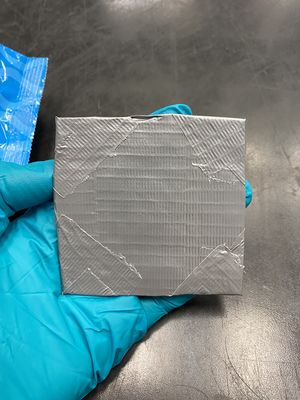

Sheared a lead sheet into 6 rough 3"x3" squares to be used for attenuation measurements with NaI detectors

Lead pieces were wiped down with a wet wipe, duct taped, rewiped, and hammered flat.

Thickness of the lead pieces is around 0.055".

Borated Aluminum

B12 and B4C structures in aluminum

- Might be possible to separate the aluminum with elemental mercury or could melt the aluminum

- Aluminum oxide has a higher melting point (~2000C) than elemental aluminum which is still lower than B4C (~2700C)

Polyethylene

Borated Polyethylene

Virgin Polyethylene

Green Borated Polyethylene

- The concentration of boron is unknown at the current time

Light Purple Borated Polyethylene

- The concentration of boron is unknown at the current time